RFID tag and RFID tag production method

a technology of rfid tags and production methods, applied in the direction of mechanical actuation of burglar alarms, instruments, and mechanical details of semiconductor/solid-state devices, can solve problems such as failures in which rfid tags break, and achieve the effect of suppressing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Embodiments of the present invention will be described below with reference to the drawings.

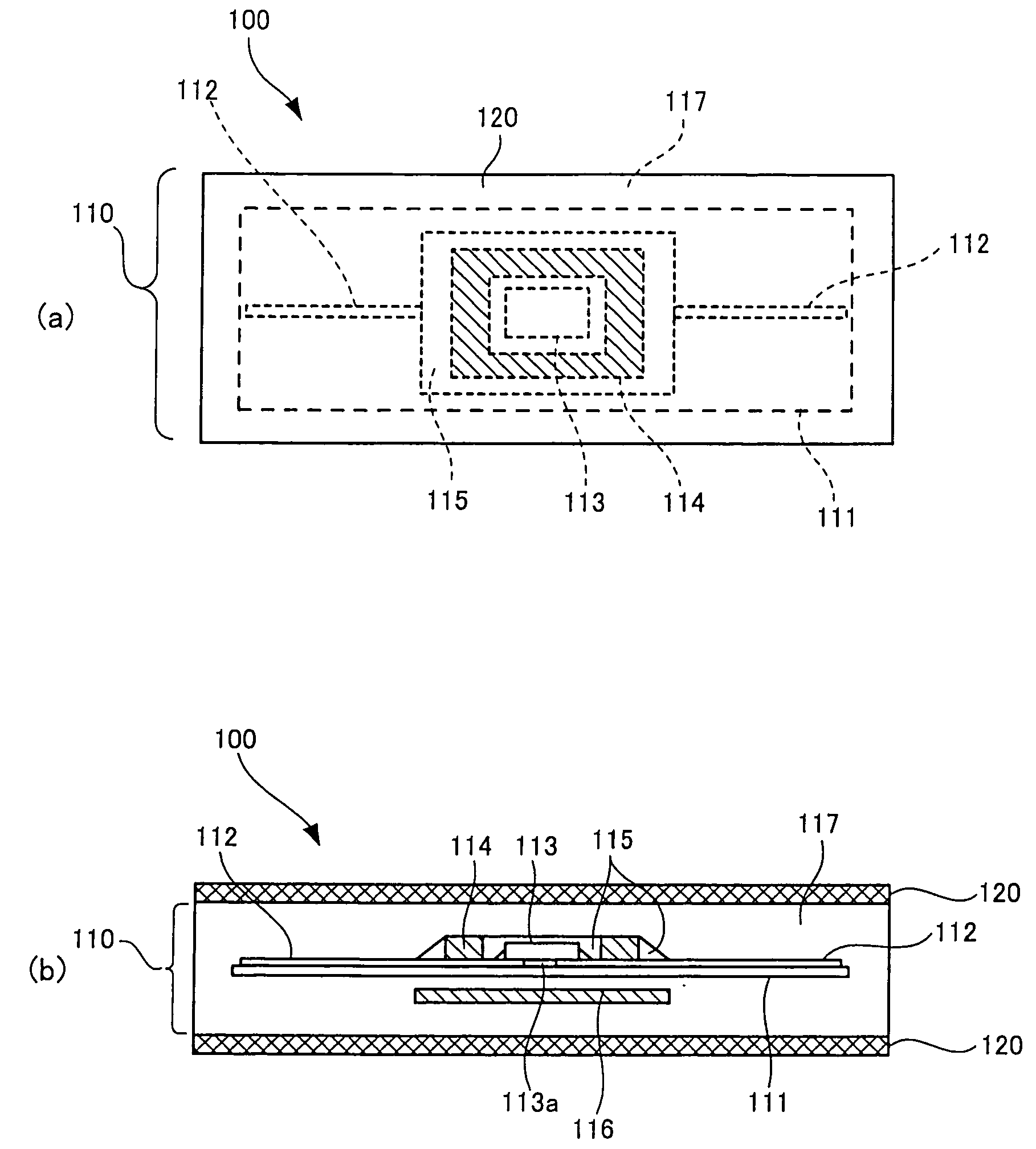

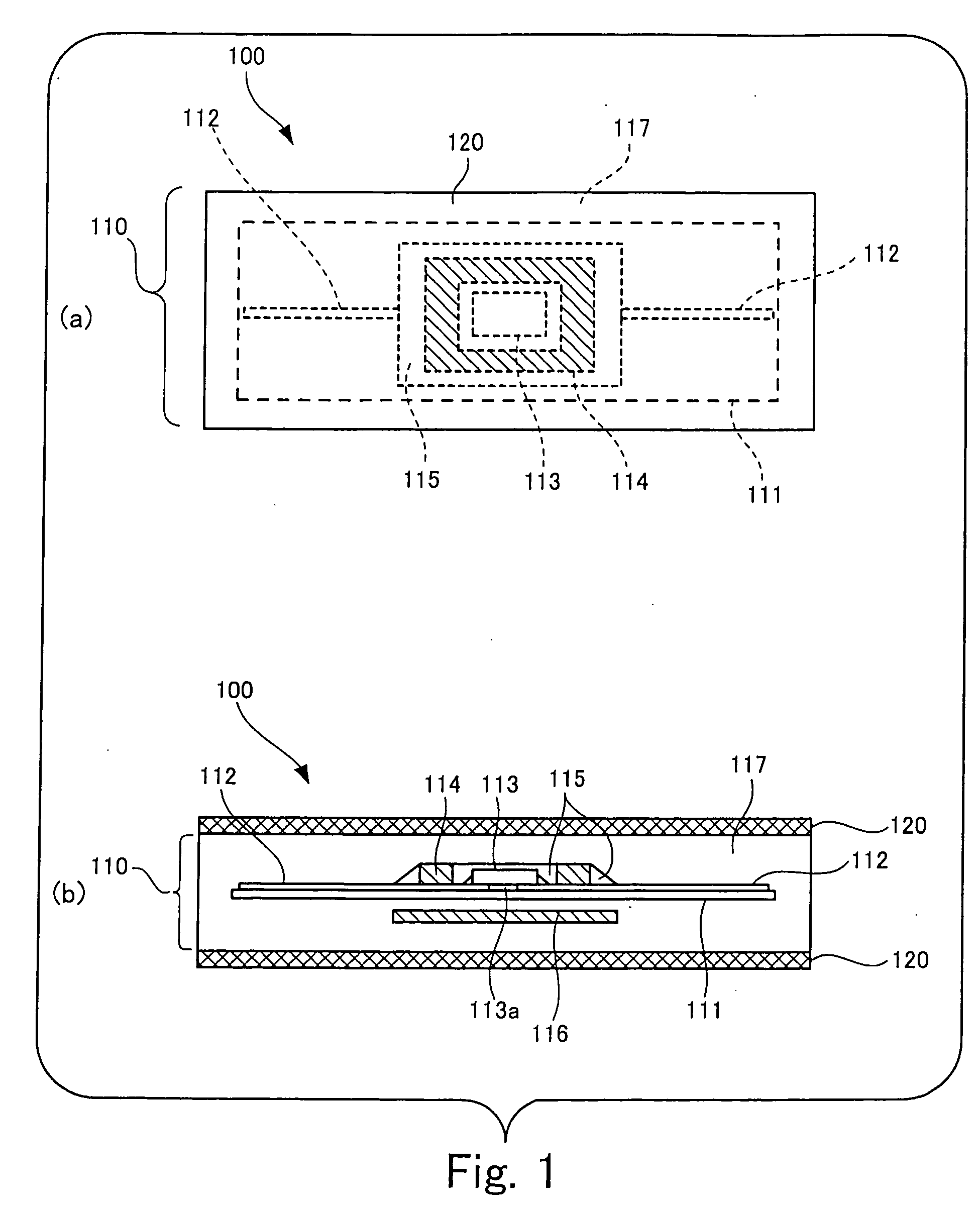

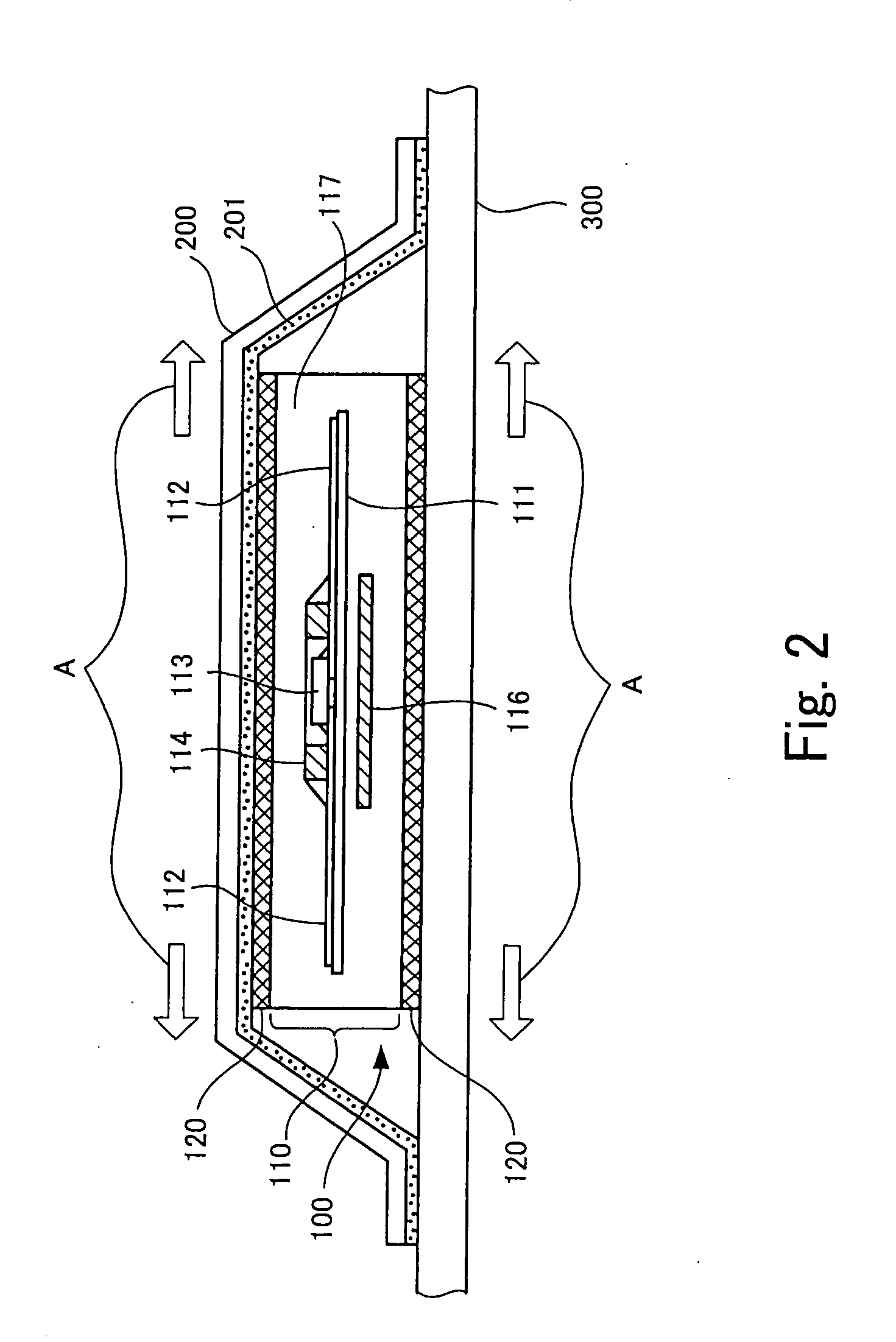

[0040]FIG. 1 is a schematic diagram that illustrates an embodiment of an RFID tag according to the present invention.

[0041]Part (a) of FIG. 1 is a top view of an RFID tag 100 as an embodiment of the RFID tag according to the present invention, in which the inner structure of the RFID tag is shown in a transparent state and part (b) of FIG. 1 shows a cross section in the longitudinal direction of the RFID tag 100.

[0042]The RFID tag 100 shown in FIG. 1 is an RFID tag which it is assumed will be attached to an article that changes shape easily, such as clothing. The RFID tag 100 has a main unit 110 that consists of a base 111 that is formed with PET film; a communication antenna 112 that is wired on the base 111; a circuit chip 113 that is electrically connected to the antenna 112 and is adhered and fixed to the base 111 by an adhesive 113a and carries out radio communication via the anten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| degree of adhesiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com