Semiconductor Module with Serial Bus Connection to Multiple Dies

a technology of serial bus and semiconductors, applied in the direction of printed circuit manufacturing, printed circuit aspects, electrical apparatus construction details, etc., can solve the problems of increasing the weight of the module, requiring separate heat spreaders to be placed, and adding significant weight to the module, so as to reduce the need for additional circuit board space, and reduce the complexity of circuit board layout and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

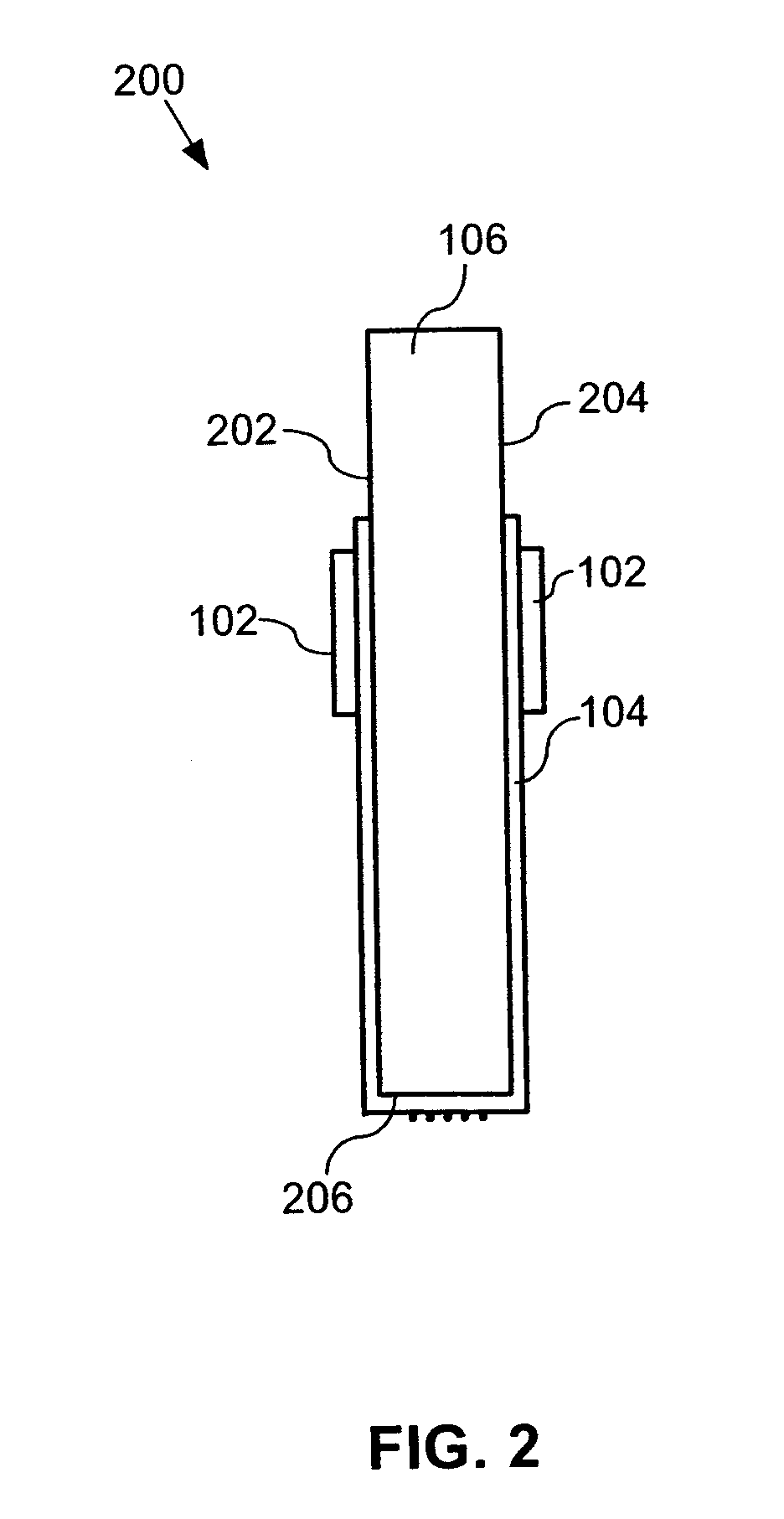

[0032]FIG. 1 is a front view of a semiconductor module 100 according to an embodiment of the invention. A semiconductor 102 is electrically connected to a plurality of traces or electrically conductive leads 108 by any conventional method such as wire bonding or thermocompression bonding. The electrically conductive leads 108 may be incorporated into flexible circuitry or tape 104, which preferably consists of copper traces within a thin dielectric substrate (such as polyimide, epoxy, etc.).

[0033] As shown in FIG. 1, the flexible circuitry 104 may be bonded, with an epoxy or the like, directly onto the side of the heat spreader 106. The heat spreader 106 is preferably made from a material with good heat dissipation properties, such as a metal.

[0034] In a preferred embodiment, two semiconductors 102 are positioned on opposing sides of the heat spreader 106. The leads 108 preferably run the length of each sides of the heat spreader 106, culminating at electrical contact points 110 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com