Measuring chip for surface plasmon resonance biosensor and method for producing the same

a surface plasmon resonance and biosensor technology, applied in the field of surface plasmon resonance biosensors, can solve the problems of lb membrane binds poorly to a metal thin film, peels off together, and conventional methods are known to be complicated, so as to achieve the effect of improving the sensitivity of the measuring chip for the surface plasmon resonance sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

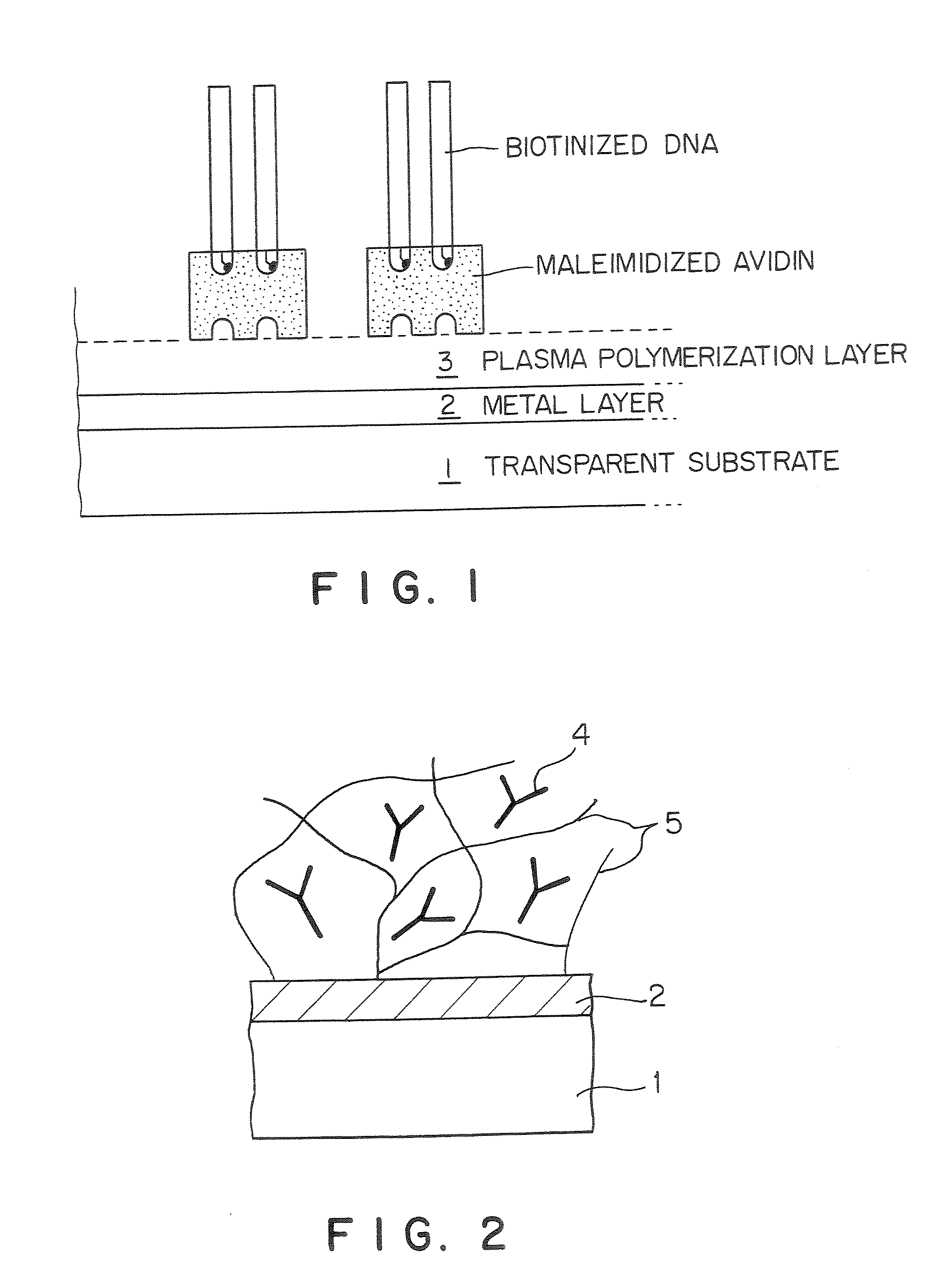

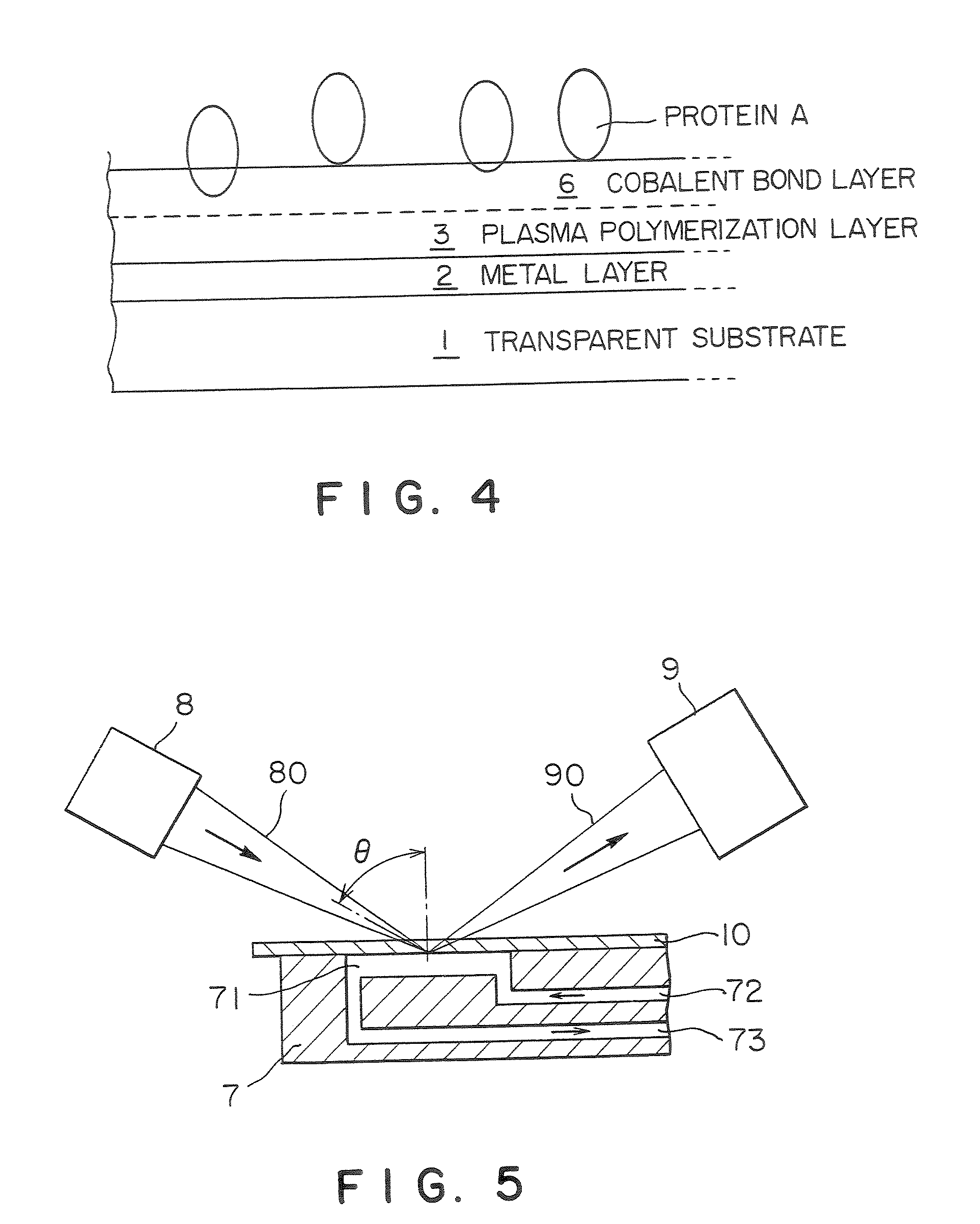

[0119] A measuring chip having layers shown in FIG. 1 on an optical recognition part was constructed.

[0120] A glass plate with a thickness of 0.15 mm (18 mm×18 mm) was used for a transparent substrate. A chrome layer and then a gold layer were deposited on this transparent substrate by sputtering. The sputtering was carried out at 100 W for 40 seconds for the chrome layer and at 100 W for 2 minutes and 30 seconds for the gold layer. The resulting chrome layer was 40 angstroms thick and the resulting gold layer was 500 angstroms thick.

[0121] A plasma polymerization layer was formed on the metal layers. An apparatus as shown in FIG. 7 was used for plasma polymerization. Ethanedithiol was used as a monomer material for the plasma polymerization layer to introduce a thiol group. Conditions for plasma polymerization were as follows:

[0122] Flow volume of monomer material: 15 sccm

[0123] Temperature: 15° C.

[0124] Pressure: 4.7 Pa

[0125] Discharge electric power: 20 W

[0126] Discharge f...

example 2

[0131] The same apparatus and method as in Example 1 were used.

[0132] Acetonitrile was used as a monomer material for the plasma polymerization layer. Conditions for plasma polymerization were as follows:

[0133] Flow volume of monomer material: 1.5 sccm+Ar dilution 15 (sccm)

[0134] Temperature: room temperature

[0135] Pressure: 4.7 Pa

[0136] Discharge electric power: 80 W

[0137] Discharge frequency: 13.56 MHz

[0138] Duration of discharge: 15 seconds.

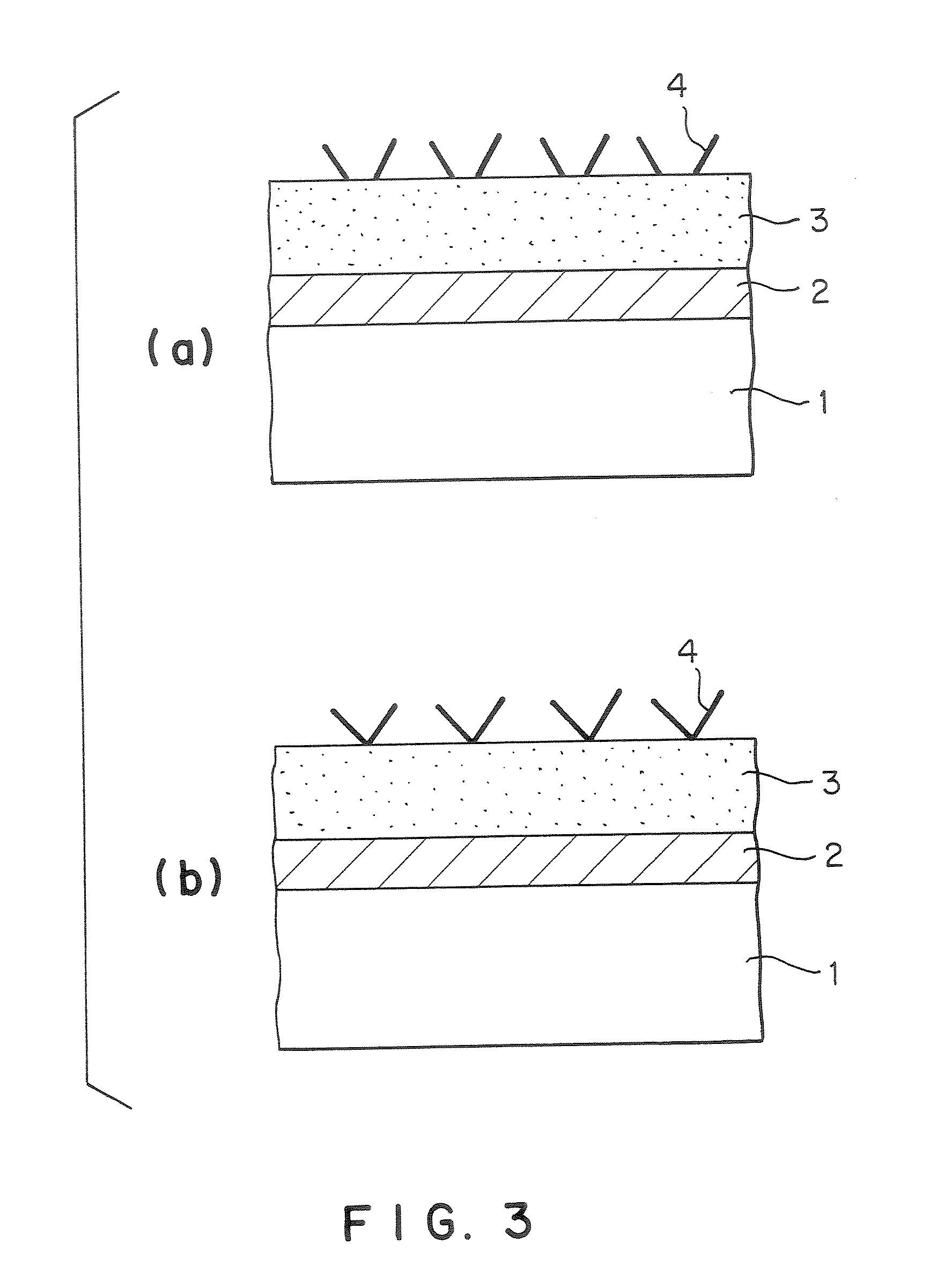

[0139] Under the conditions described above, a plasma polymerization layer was formed. The sensor chip was mounted on the cartridge block of the surface plasmon resonance biosensor, 5% glutaraldehyde was poured through a flow route into the measuring cell at a flow rate of 5 μl / min for 10 minutes and avidin (concentration: 20 μg / ml) was also poured at a flow rate of 5 μl / min to immobilize for 60 minutes. 10 μM biotin-labeled probe RNA were then poured at a flow rate of 1 μl / min to immobilize the probe RNA for 10 minutes. DNA (7.5×10−7 ...

example 3

[0141] The same apparatus and method as in Example 1 were used.

[0142] Conditions for plasma polymerization layer formation were the same as in Example 2.

[0143] Under the conditions described above, a plasma polymerization layer was formed.

[0144] The sensor chip was mounted on the cartridge block of the surface plasmon resonance biosensor, 5% glutaraldehyde was poured through a flow route into the measuring cell at a flow rate of 5 μl / min for 10 minutes and streptoavidin (concentration: 20 82 g / ml) was also poured at a flow rate of 5 μl / min to immobilize for 60 minutes. 10 μM biotin-labeled probe RNA was then poured at a flow rate of 1 μl / min for 10 minutes to immobilize the probe RNA. DNA (7.5×10−7 M) having a DNA sequence complementary to this probe RNA was introduced and after the reaction, a signal of about 375 RU was obtained.

Concentration ofComplementaryDNA (μM)0.000750.00750.0750.757.575RU7.518.7575375750825

[0145] It was confirmed by the XPS analysis that the resulting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com