Printed wiring board including power supply layer and ground layer

a technology of printed wiring and ground layer, which is applied in the incorporation of printed electric components, cross-talk/noise/interference reduction, printed circuit aspects, etc., can solve the problem that the noise of power supply is forced to inevitably pass through the electrically-conductive pieces, and the electric current is forced to be qui

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

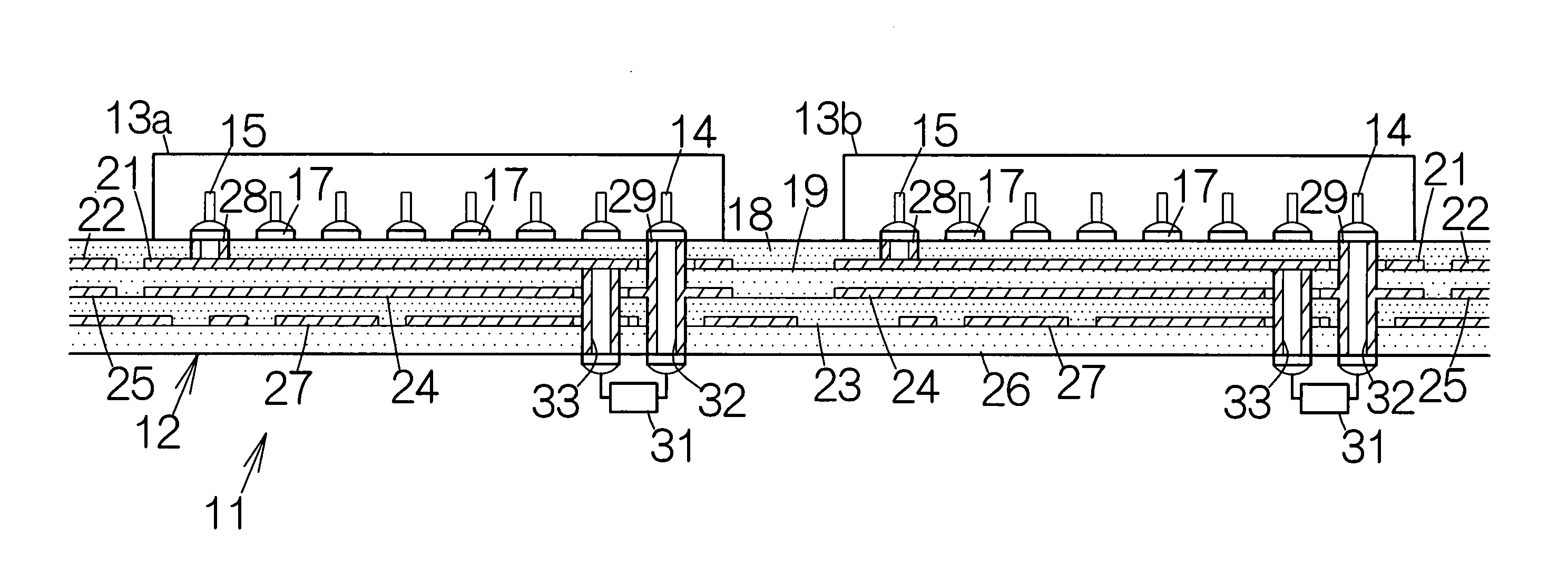

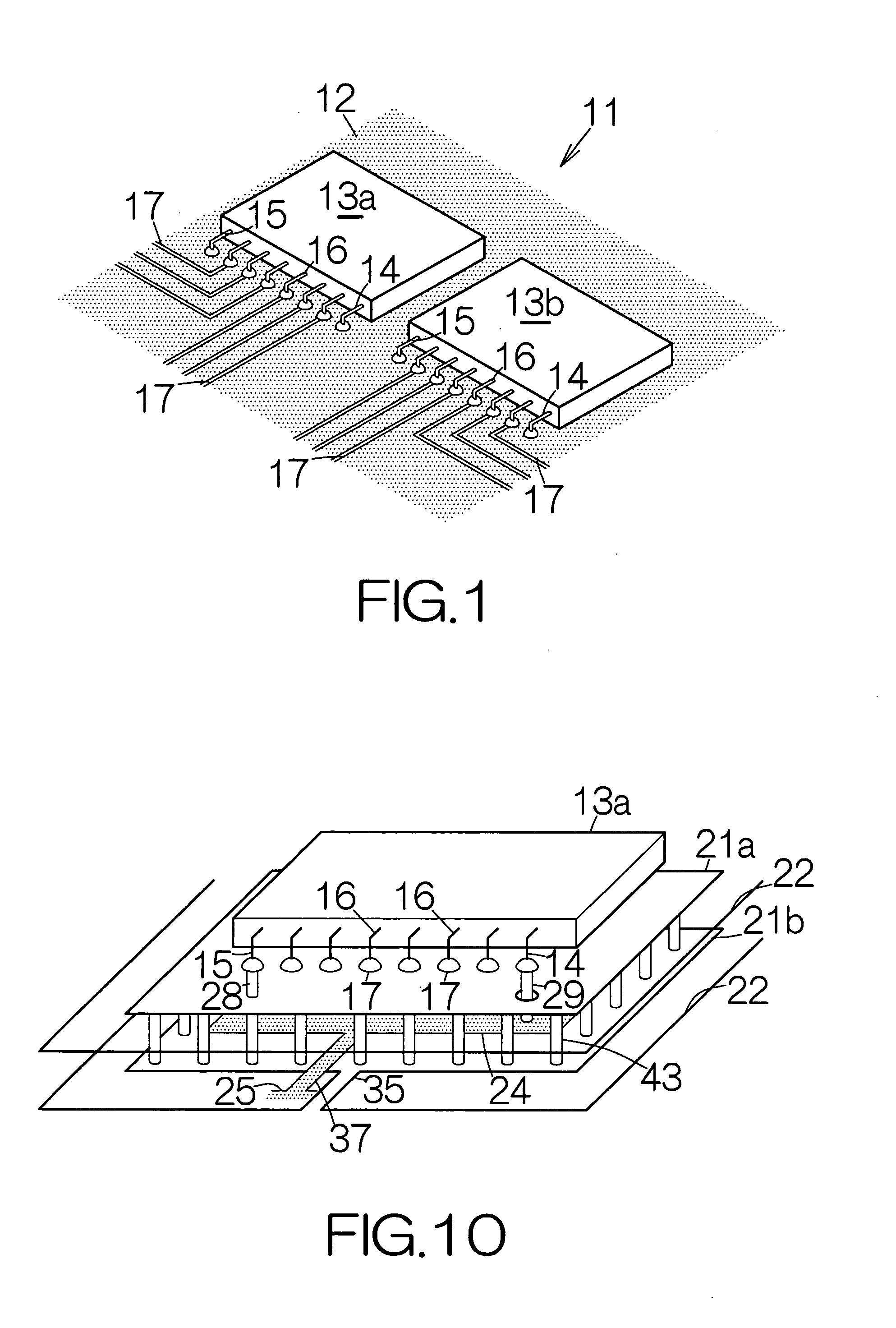

[0027]FIG. 1 schematically illustrates a printed circuit board unit 11 according to an embodiment of the present invention. The printed circuit board unit 11 includes a printed wiring board 12. One or more LSI (Large-Scale Integrated circuit) chip or chips 13a, 13b, . . . are mounted on the front surface of the printed wiring board 12, for example. A power supply pin 14, a ground pin 15 and signal pins 16 are connected to each of the LSI chips 13a, 13b.

[0028] Wiring patterns 17 are formed on the surface of the printed wiring board 12. The wiring patterns 17 may be made of an electrically-conductive material such as copper, for example. The signal pins 16 are soldered to the corresponding wiring patterns 17, respectively.

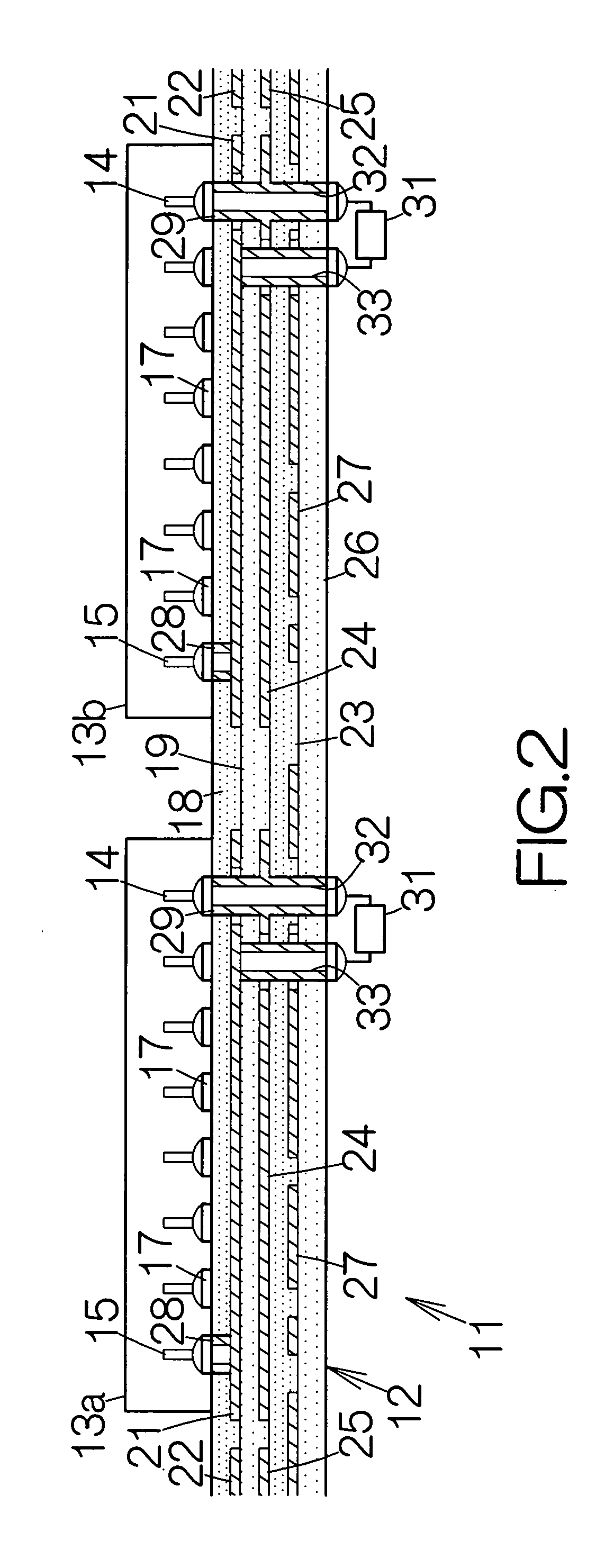

[0029] As shown in FIG. 2, the wiring patterns 17 are received on the uppermost layer of the printed wiring board 12, namely the upper surface of a first insulating layer 18. The first insulating layer 18 is received on the upper surface of a second insulating laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com