Multilayer ceramic substrate and its production method

a technology of ceramic substrate and production method, applied in the field of multi-layer ceramic substrate, can solve the problems of difficult to put molded body blocks into the spaces in the laminated body with high accuracy, and low degree of flexibility in design, so as to prevent the occurrence of separation between the substrates, increase the degree of flexibility in circuit design, and achieve the same pressing compressibility level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

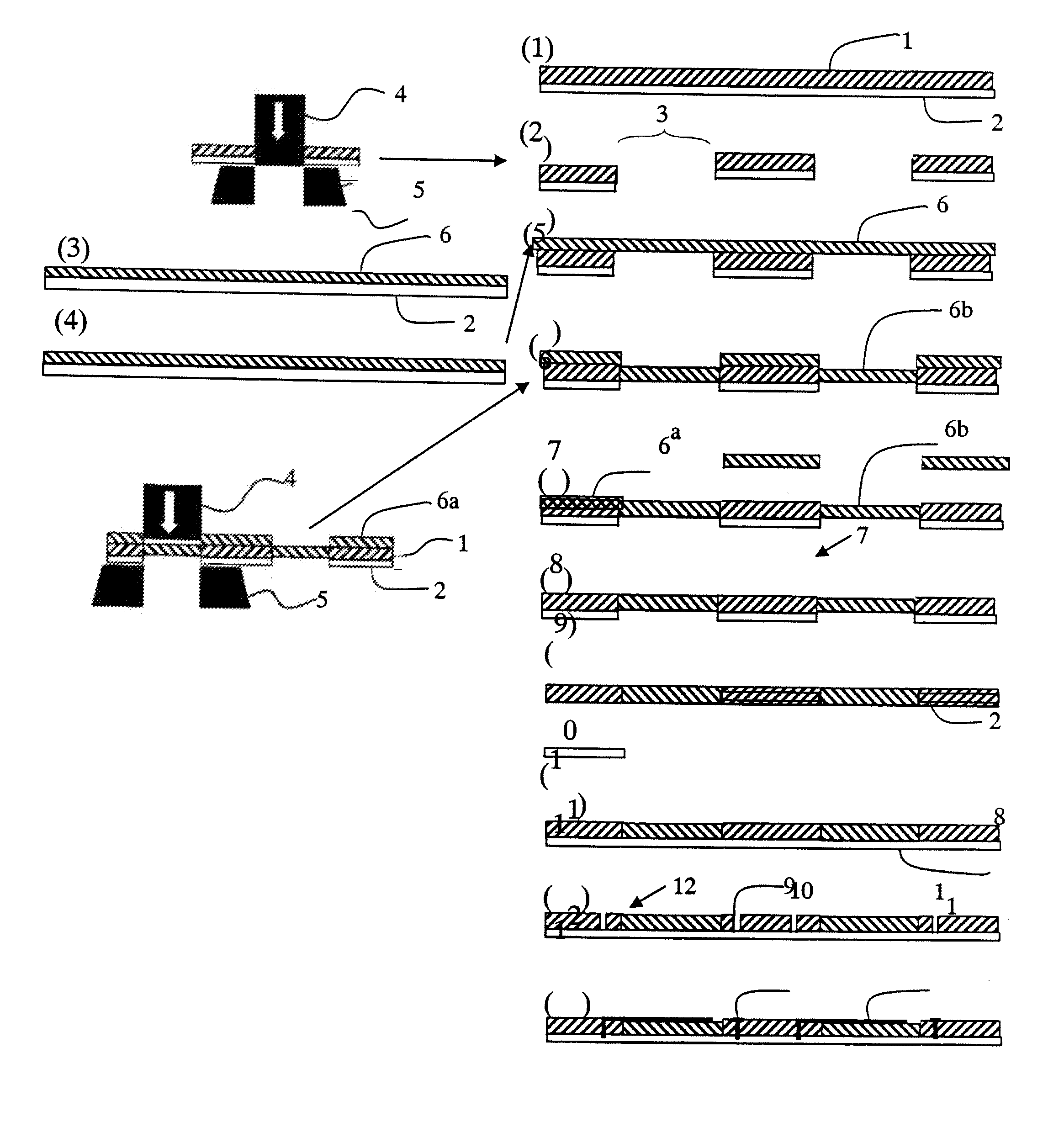

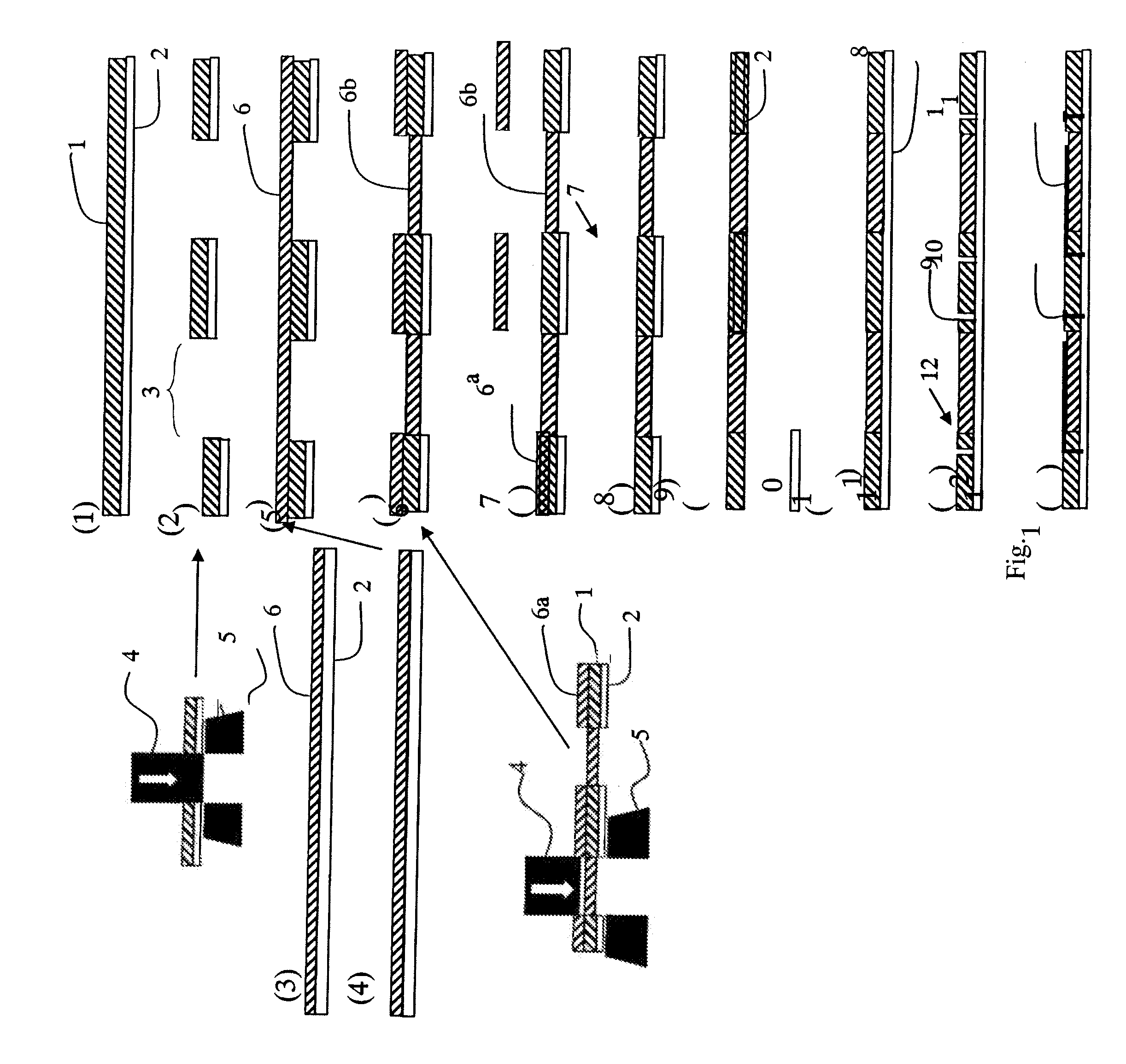

Method used

Image

Examples

example 1

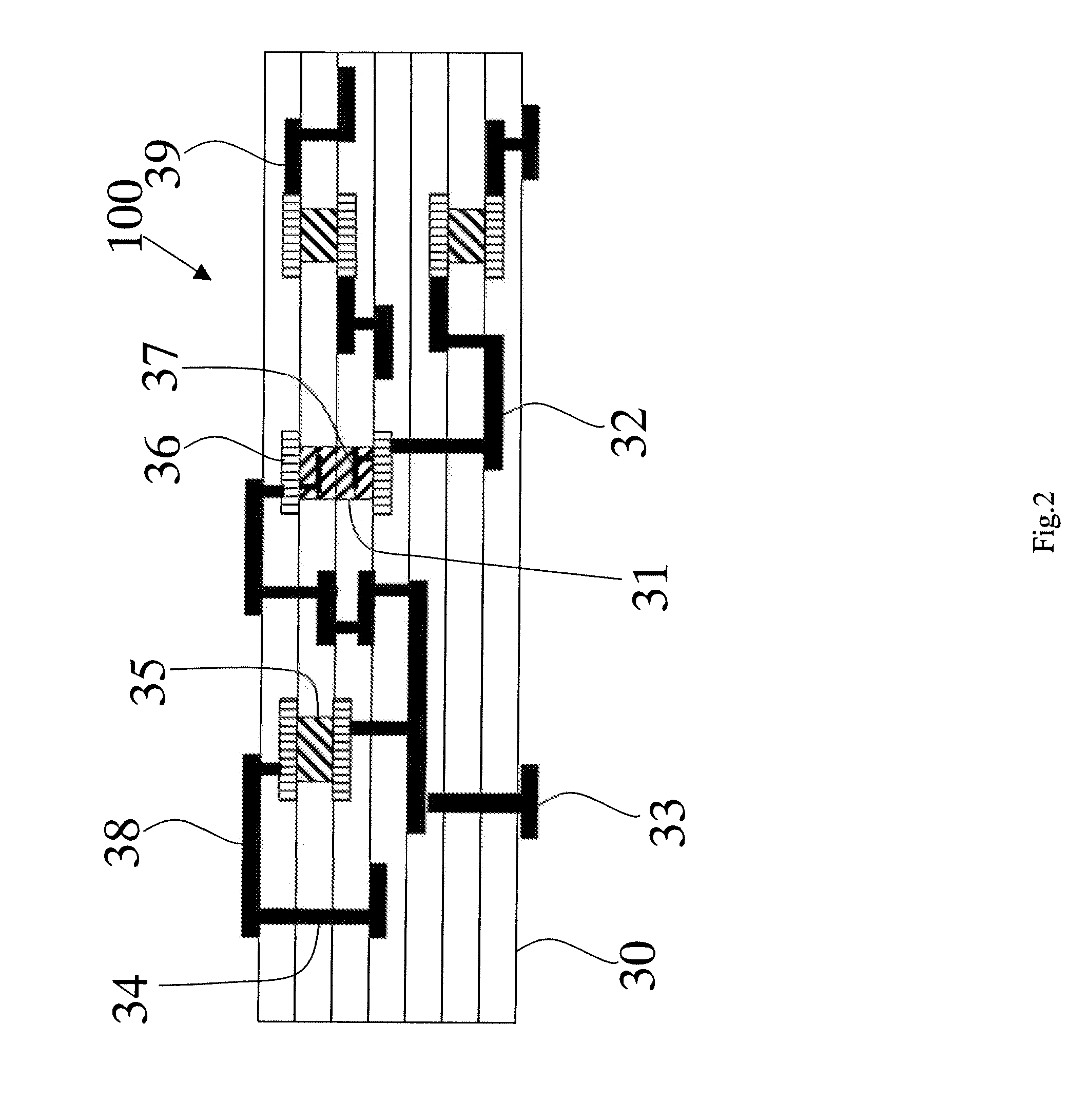

[0055] A multilayer ceramic substrate having a capacitor element shown in FIG. 3 was formed, and capacitance and IR were measured. A fired layer 21 of the first green sheet was made to have a composition (SiO2—B2O3—Al2O3—MgO—CaO—SrO) whose dielectric constant E was 7.3 after firing. A fired layer 22 of the second green sheet was made to have a composition (SiO2—Al2O3—La2O3—B2O3—BaO—TiO2—Bi2O3—Nd2O3—SrO) whose dielectric constant E was 21.1 after firing. The size after firing of the second green sheet inserted in the first green sheet was made 2.57 mm×2.57 mm×40 μm. The size of an internal electrode was 2.13 mm×2.13 mm. An external electrode is denoted by a reference numeral 23. This was Example 1.

example 2

[0056] Similarly, the fired layer 21 of the first green sheet was made to have a composition (BaO—Al2O3—SiO2—B2O3) whose dielectric constant E was 5.9 after firing. The fired layer 22 of the second green sheet was made to have a composition (BaO—Nd2O3—TiO2—B2O3—CaO—ZnO) whose dielectric constant E was 72.3 after firing. The size after firing of the second green sheet 22 inserted in the first green sheet 21 was made 2.57 mm×2.57 mm×40 μm. The size of the internal electrode was made 1.71 mm×1.71 mm. This was Example 2.

[0057] The relationship between capacitor capacity and insulation resistance of Example 1, which was measured under conditions that a frequency for capacity measurement was 1 kHz and a voltage for IR measurement was 10 V, is shown in FIG. 4. The relationship between capacitor capacity and insulation resistance of Example 2, which was measured under conditions that a frequency for capacity measurement was 1 kHz and a voltage for IR measurement was 10 V. is shown in FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com