[0009] An object of the present invention is to provide a control apparatus or the like for an internal

combustion engine that can restrain occurrence of nonuniformity of cylinders with respect to each other in terms of intake air quantity and internal EGR quantity.

[0011] In accordance with the present invention, in the case where the torque acts in the opposite direction to the camshaft rotational direction, the phase in which the valve is closed is advanced and, in the case where the torque acts in the camshaft rotational direction, the phase is retarded. Thus, for a cylinder, in the case where the torque acting in the opposite direction to the camshaft rotational direction could cause

delay of the phase (timing) in (at) which the intake valve or

exhaust valve is closed, the phase in which the intake valve or

exhaust valve is closed can be advanced. Accordingly, occurrence of

delay of the phase in which the intake valve or exhaust valve is closed can be restrained. Further, for a cylinder, in the case where the torque acting in the camshaft rotational direction could cause advance of the phase in which the intake valve or exhaust valve is closed, the phase in which the intake or exhaust valve is closed can be retarded. Accordingly, occurrence of advance of the phase in which the intake valve or exhaust valve is closed can be restrained. Thus, the control apparatus for the internal

combustion engine can be provided that can restrain occurrence of displacement of the phase in which the intake valve or exhaust valve of each cylinder is actually closed with respect to a phase determined under control, and can restrain occurrence of nonuniformity of cylinders with respect to each other in terms of quantity of air taken into the cylinder and internal EGR quantity.

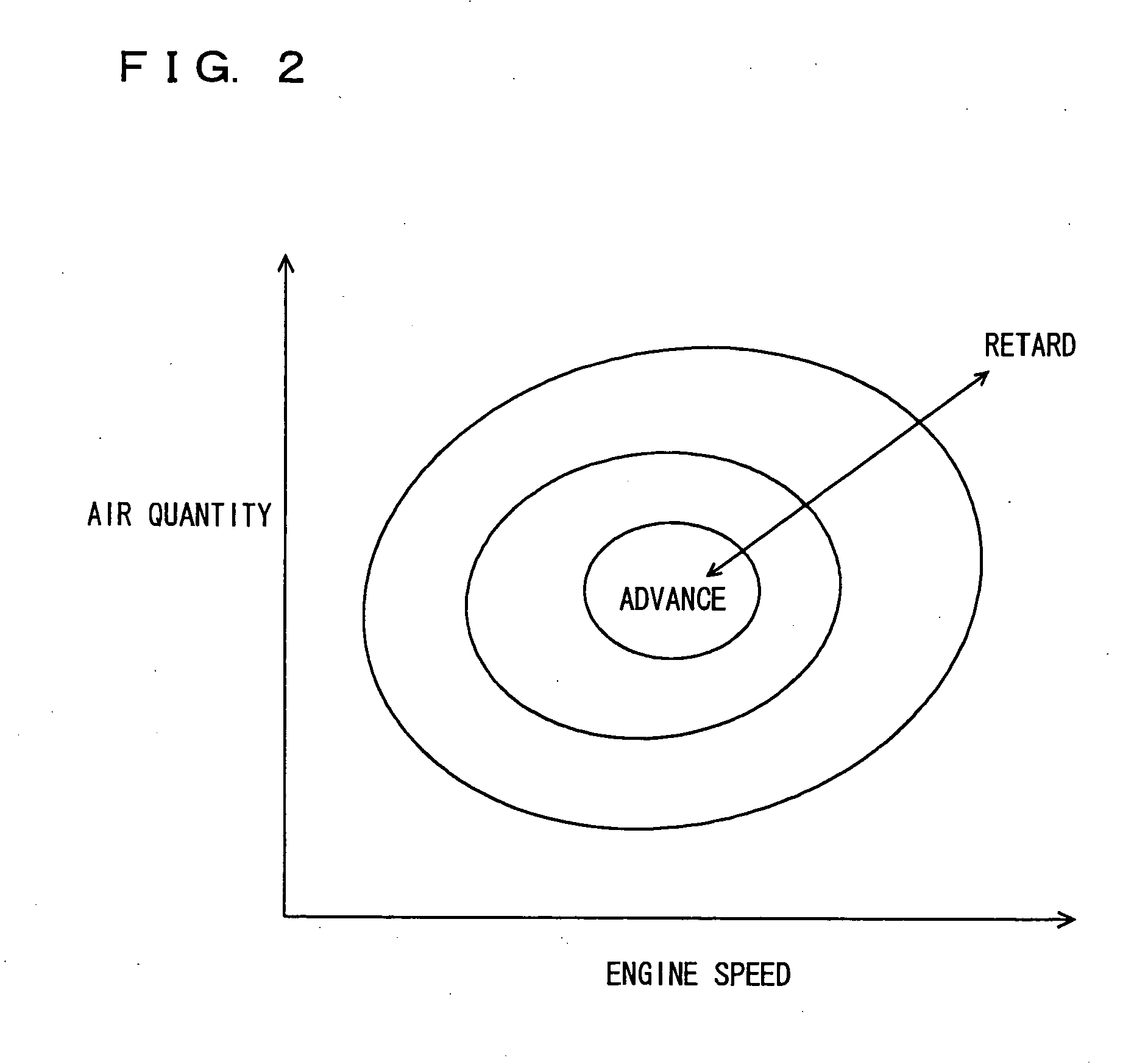

[0013] In accordance with the present invention, as the torque acting in the opposite direction to the camshaft rotational direction is larger, the phase of the intake valve or exhaust valve is advanced to a greater extent. Further, as the torque acting in the camshaft rotational direction is larger, the phase of the intake valve or the exhaust valve is retarded to a grater extent. Accordingly, as

delay in phase in which the intake valve or exhaust valve is closed is larger, the phase in which the intake valve or exhaust valve is closed can be advanced to a greater extent. Further, as advance in phase in which the intake valve or exhaust valve is closed is larger, the phase in which the intake valve or exhaust valve is closed can be retarded to a greater extent. Thus, for each cylinder, occurrence of displacement of the phase in which the intake valve or exhaust valve is actually closed with respect to a phase determined under control can be restrained, and occurrence of nonuniformity of cylinders with respect to each other in terms of intake air quantity and internal EGR quantity can be restrained.

[0015] In accordance with the present invention, as a higher camshaft rotational speed causes a larger torque acting in the opposite direction to the camshaft rotational direction, the phase of the intake valve or exhaust valve is advanced to a greater extent. Further, as a higher camshaft rotational speed causes a larger torque acting in the camshaft rotational direction, the phase of the intake valve or exhaust valve is retarded to a greater extent. Accordingly, as delay in phase in which the intake valve or exhaust valve is closed is larger, the phase in which the intake valve or exhaust valve is closed can be advanced to a greater extent. Further, as advance in phase in which the intake valve or exhaust valve is closed is larger, the phase in which the intake valve or exhaust valve is closed can be retarded to a greater extent. Thus, for each cylinder, occurrence of displacement of the phase in which the intake valve or exhaust valve is actually closed with respect to a phase determined under control can be restrained, and occurrence of nonuniformity of cylinders with respect to each other in terms of intake air quantity and internal EGR quantity can be restrained.

[0017] In accordance with the present invention, as a higher load of the internal

combustion engine causes a larger torque acting in the opposite direction to the camshaft rotational direction, the phase of the intake valve or exhaust valve is advanced to a greater extent. Further, as a higher load of the internal combustion engine causes a larger torque acting in the camshaft rotational direction, the phase in which the intake valve or exhaust valve is closed can be retarded to a greater extent. Accordingly, as delay in phase in which the intake valve or exhaust valve is closed is larger, the phase in which the intake valve or exhaust valve is closed can be advanced to a greater extent. Further, as advance in phase in which the intake valve or exhaust valve is closed is larger, the phase in which the intake valve or exhaust valve is closed can be retarded to a greater extent. Thus, for each cylinder, occurrence of displacement of the phase in which the intake valve or exhaust valve is actually closed with respect to a phase determined under control can be restrained, and nonuniformity of cylinders with respect to each other in terms of intake air quantity and internal EGR quantity can be restrained.

Login to View More

Login to View More  Login to View More

Login to View More