Metal salts of quinolinols and quinolinol derivatives as corrosion inhibitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

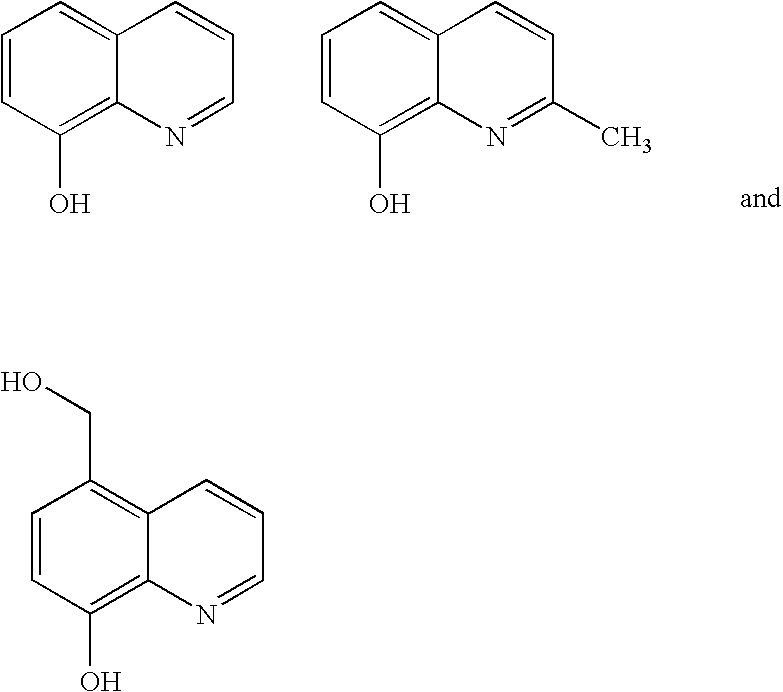

[0041] Preparation of Bis-quinolinol

According to the procedure described by Donald. S. Noyce and Lloyd J. Dolby, Amino- and Chloromethylation of 8-Quinolinol. Mechanism of Preponderant ortho Substitution in Phenols under Mannich Conditions, in The Journal of Organic Chemistry, Volume 26, number 10, Oct. 24, 1961, at pages 4078 to 4083, bis-quinolinol was prepared via the reaction of 8-quinolinol and an excess of formaldehyde in an aqueous hydrochloric acid solution. 8-Quinolinol (29.0 grams, 0.2000 mol) and hydrochloric acid (37%, 85 mL) were combined in a four-neck, 250 mL, round bottom flask equipped with a magnetic stir bar, reflux condenser and hot oil bath. Initially, an exotherm of ˜25° C. was observed upon mixing these reagents. Formaldehyde (37%, 9 mL), was then added which resulted in a change from a clear yellow solution to a gold solution. The mixture was heated at reflux for 90 minutes. During this time heavy acidic fumes were generated. After mixing for 15 minutes at...

example 2

[0045] Preparation of Quinolinol / piperidine

Quinolinol can be volatile, and in this example, a quinolinol / piperidine derivative was prepared in order to increase the bulk and reduce the volatility of quinolinol. The asymmetry of this derivative promoted a lower melting point than that found for the bis-quinolinol. Quinolinol / piperidine was prepared in a melt by the reaction of equimolar amounts of 8-quinolinol, piperidine and paraformaldehyde.

[0046] 8-Quinolinol (29.0 grams, 0.2000 mol), piperidine (17.0 grams, 0.2000 mol) and paraformaldehyde (6.0 grams, 0.2000 mol) were charged to a 100 mL 3-neck round bottom flask equipped with a mechanical mixer, thermometer and reflux condenser. With mixing, the solids partially dissolved to an opaque gold liquid and the reaction temperature rose from room temperature to 71° C. within five minutes. Mixing was continued until the reaction temperature dropped to ˜60° C. At this point, the flask was placed in a hot oil bath preheated to 100° C....

example 3

[0048] Preparation of Hydroxy-functionalized Quinolinol

An hydroxy functionalized quinolinol intermediate was prepared via the reaction of equimolar amounts of 8-quinolinol and formaldehyde in an aqueous hydrochloric acid solution. (Note that quinolinol was synthesized similarly but with a molar excess of formaldehyde relative to 8-quinolinol). The product of this reaction showed improved solubility over bis-quinolinol and was more easily characterized. The synthesis procedure was obtained from Donald. S. Noyce and Lloyd J. Dolby, Amino- and Chloromethylation of 8-Quinolinol. Mechanism of Preponderant ortho Substitution in Phenols under Mannich Conditions, in The Journal of Organic Chemistry, Volume 26, number 10, Oct. 24, 1961, at pages 4078 to 4083.

[0049] 8-Quinolinol (120.0 grams, 0.8267 mol), hydrochloric acid (37%, 352 mL) and formaldehyde (37%, 67.7 grams), were combined in a four-neck one liter round bottom flask equipped with a magnetic stir bar, thermometer, reflux conde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com