High-speed machining tool

a high-speed machining and tool technology, applied in the field of components, can solve the problems of affecting the work environment, corrosion of tools, and complicated processes, and achieve the effects of high speed, improved cutting resistance, heat resistance, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Cutting Resistance Test of the Uncoated Tool

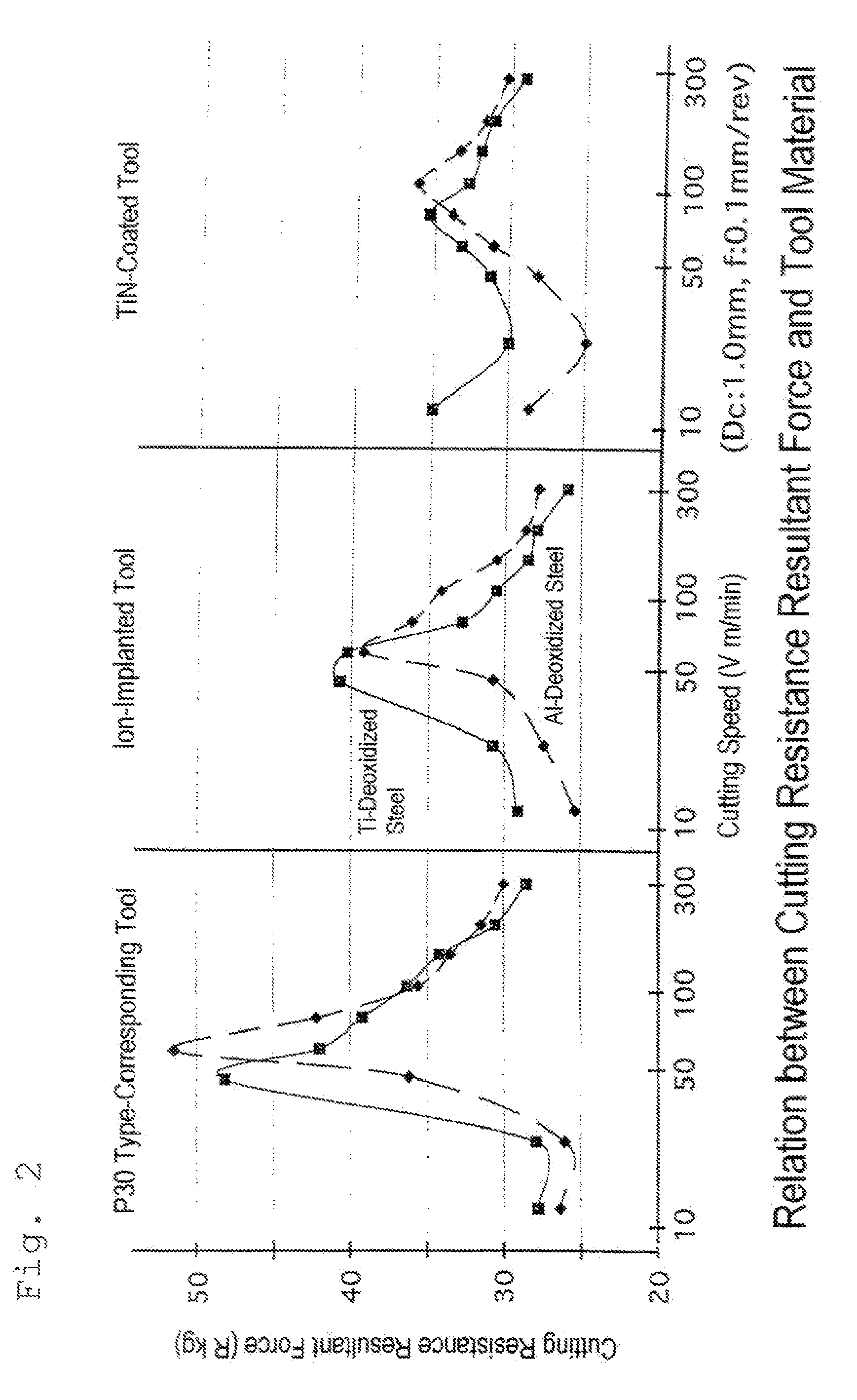

[0059] The ion-implanted P10 tool, and an ion-unimplanted TiN-coated P10 tool were subjected to a dry cutting test in a low speed to a high speed region to measure cutting resistance. As a control, a P30 tool (an untreated product which has not been ion-implanted or coated, composition WC-TiC (TaC) 8%-Co 10%, MITSUBISHI MATERIALS CORP., shape: comparable to P10 tool, model: UT20T) was also subjected to the test. The cutting conditions were as follows: [0060] Depth of cut Dc: 1.0 mm [0061] Feed rate f: 0.1 mm / rev [0062] Work materials: Al-deoxidized steel and Ti-deoxidized steel of Table 1 [0063] Cutting speed: Increased from 10 m / min to 300 m / min with the same tool

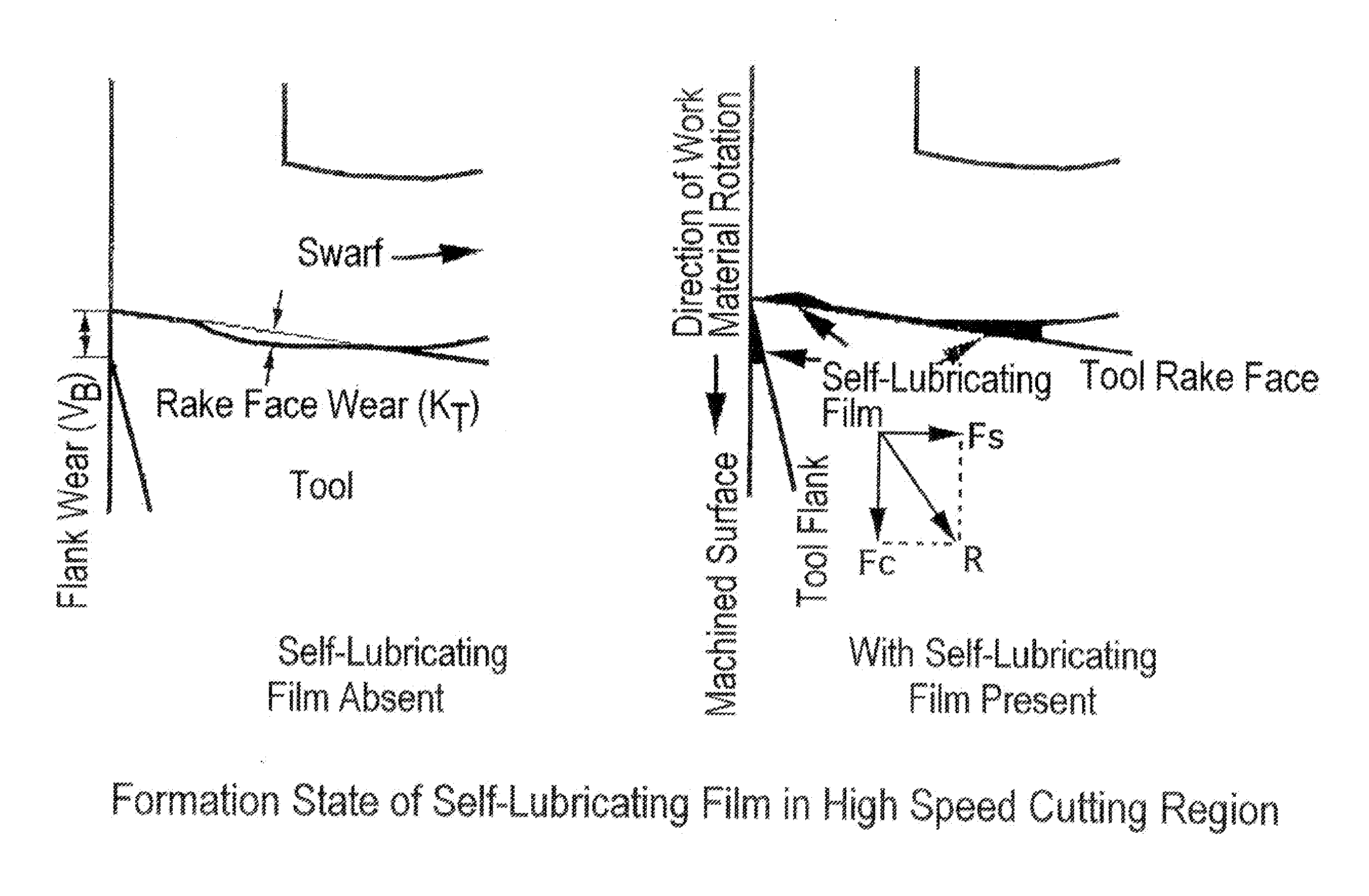

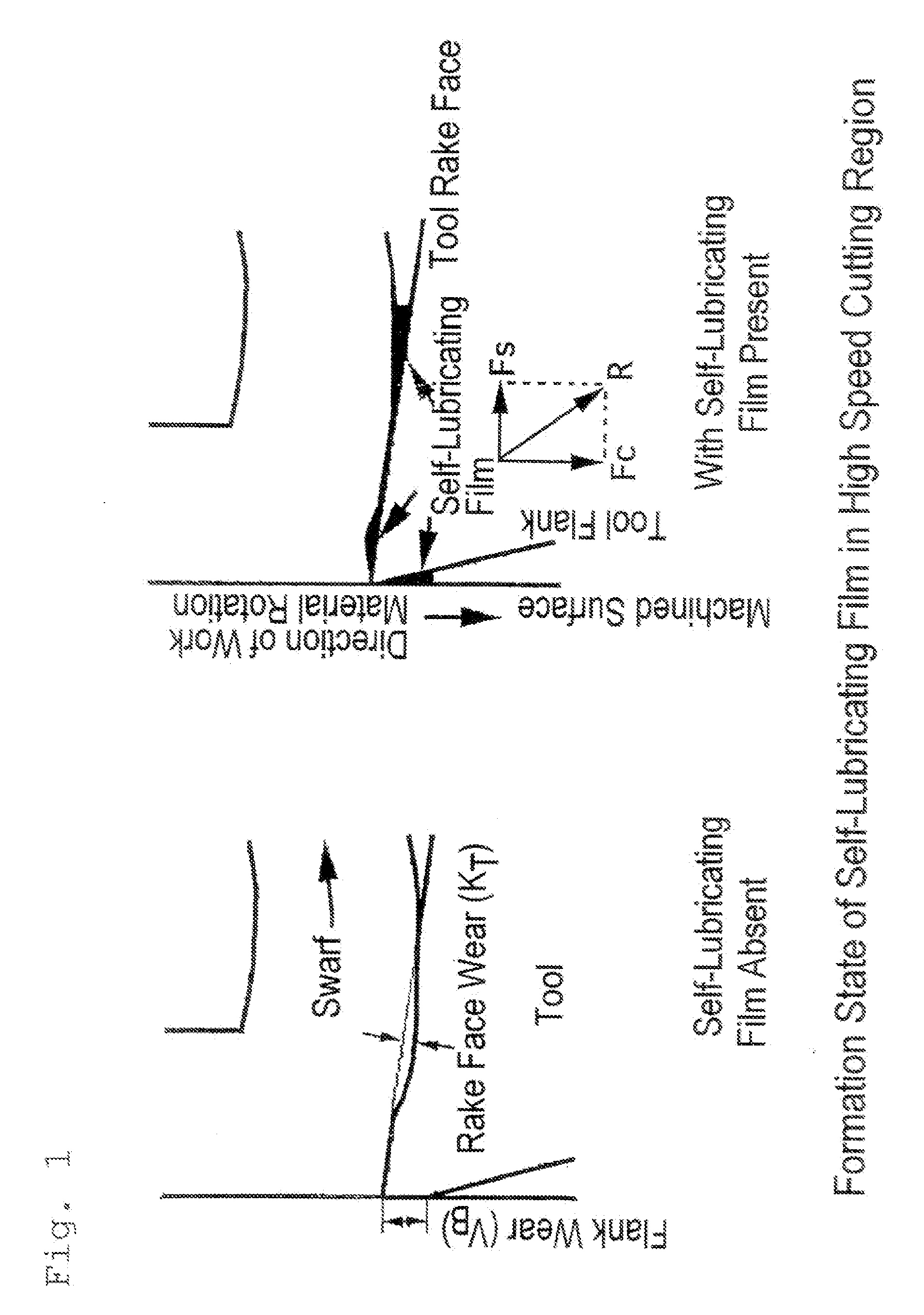

[0064] A force exerted on the tool during cutting, and the formation of a self-lubricating film are shown in FIG. 1.

[0065]FIG. 2 shows the cutting speed dependence of a cutting resistance resultant force (R). All of the tools had maximum values in the medium speed region (40 ...

example 2

Wear Characteristics of Ion-Implanted Uncoated Tool

[0071] A wear test, by dry cutting, of the P10 ion-implanted tool was conducted. The conditions for the test are as follows: [0072] Cutting speed V: 50-250 m / min [0073] Cutting length: 500 m [0074] (Cutting time depends on the cutting speed: for example, it is 10 minutes at V=50 m / min, and 2 minutes at B=250 m / min) [0075] Work materials: Al-deoxidized steel and Ti-deoxidized steel described above

[0076] Other conditions were the same as those in Example 1.

[0077] The rake face wear depth (kT) and flank wear width (VB) of the tool after the test were measured to evaluate wear (FIG. 5). As shown in FIG. 5, when the Ti-deoxidized steel is used as the work material, kT and VB are smaller, and thus wear characteristics are improved.

example 3

Analysis of Self-Lubricating Film of Ion-Implanted Uncoated Tool

[0078] In connection with the ion-implanted P10 tool used in the same cutting as in Example 1, the resulting self-lubricating film was observed with an optical microscope (FIG. 6). As a result, the formation of the film on the surface of contact with the work material was noted.

[0079] The composition of the film was measured by XAM (FIGS. 7(a) to 7(d). As shown in FIGS. 7(a) to 7(d), Ti—Mn—Si compound oxides are formed in the vicinity of the surface of contact with the work material.

[0080] In FIGS. 7(a) to 7(d), W, Si, Mn, Al and Ti were measured in the film region, and their masses were calculated on the assumption that they would exist as WC, SiO2, MnO, Al2O3 and TiO2, respectively, and the sum of these masses was taken as 100%. The values of the mass % obtained for each compound based on this assumption were indicated for the respective elements in FIGS. 7(a) to 7(d). In regard to Ti, for example, the mass ration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com