Polyester compositions comprising minimal amounts of cyclobutanediol

a technology of cyclobutanediol and composition, which is applied in the field of polymer compositions, can solve the problems of insufficient equipment used in the industry to manufacture or post-polymerization process these materials, and the difficulty of forming amorphous articles by methods known in the art such as extrusion, injection molding, etc., and achieves the effect of low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

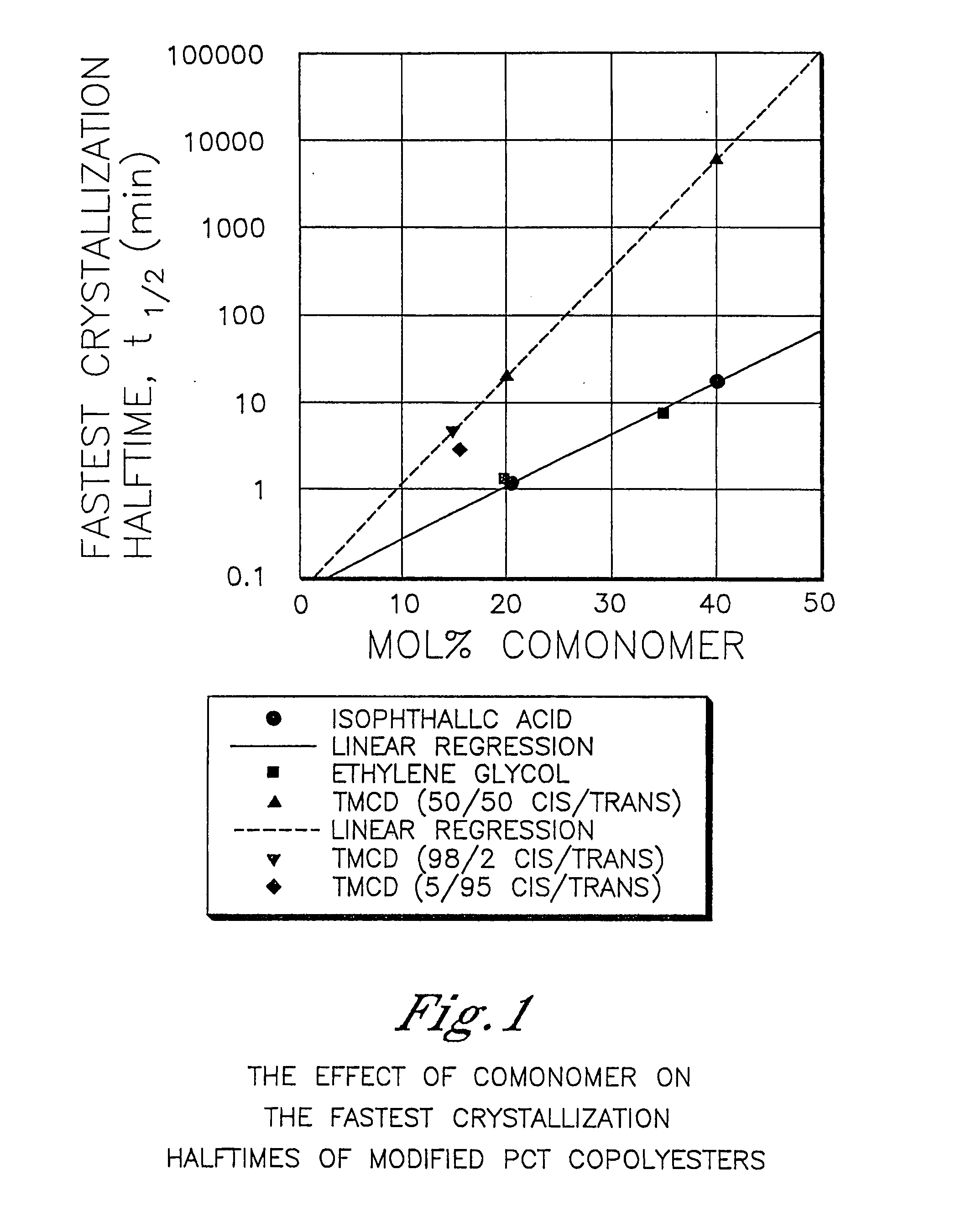

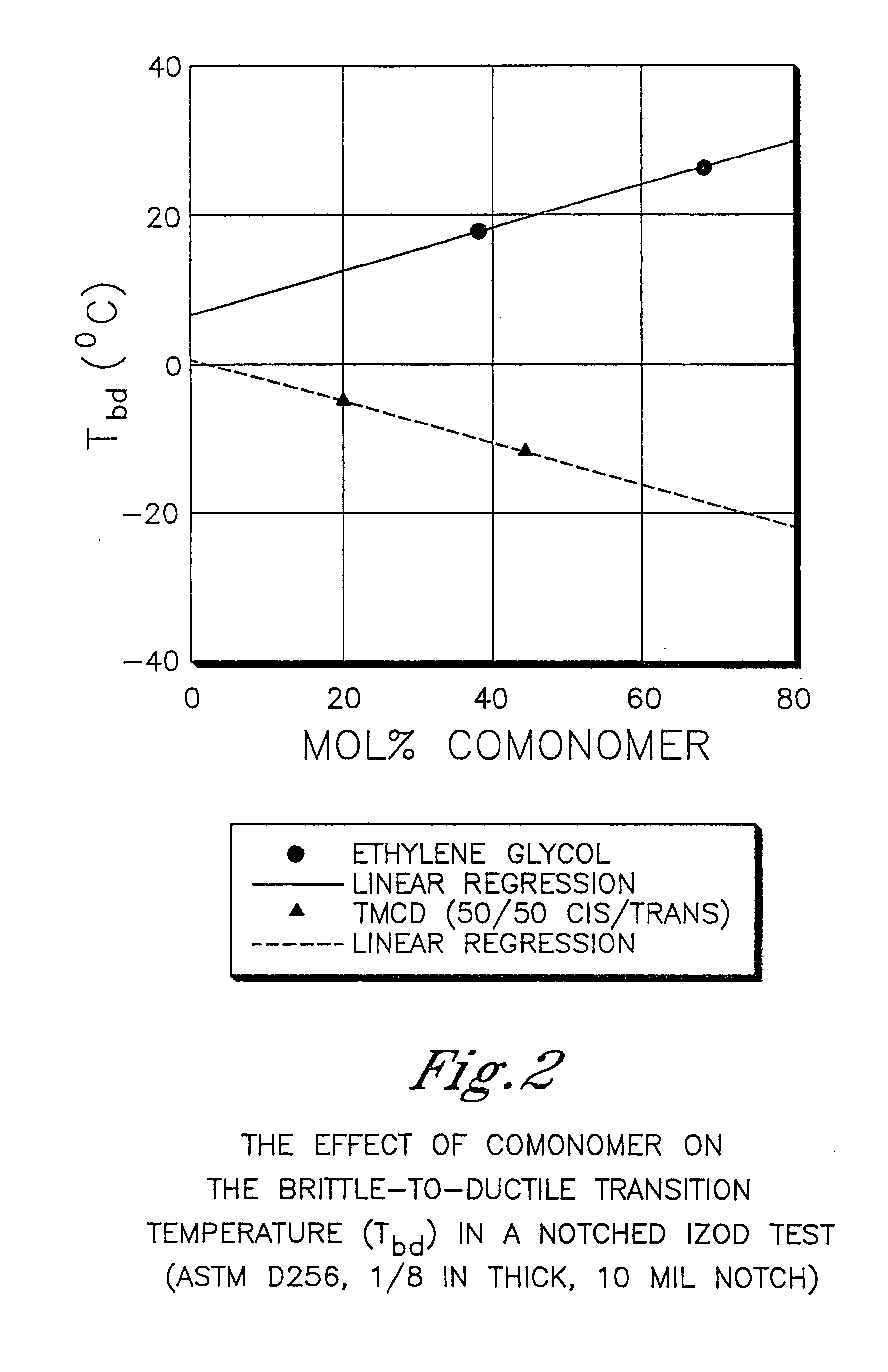

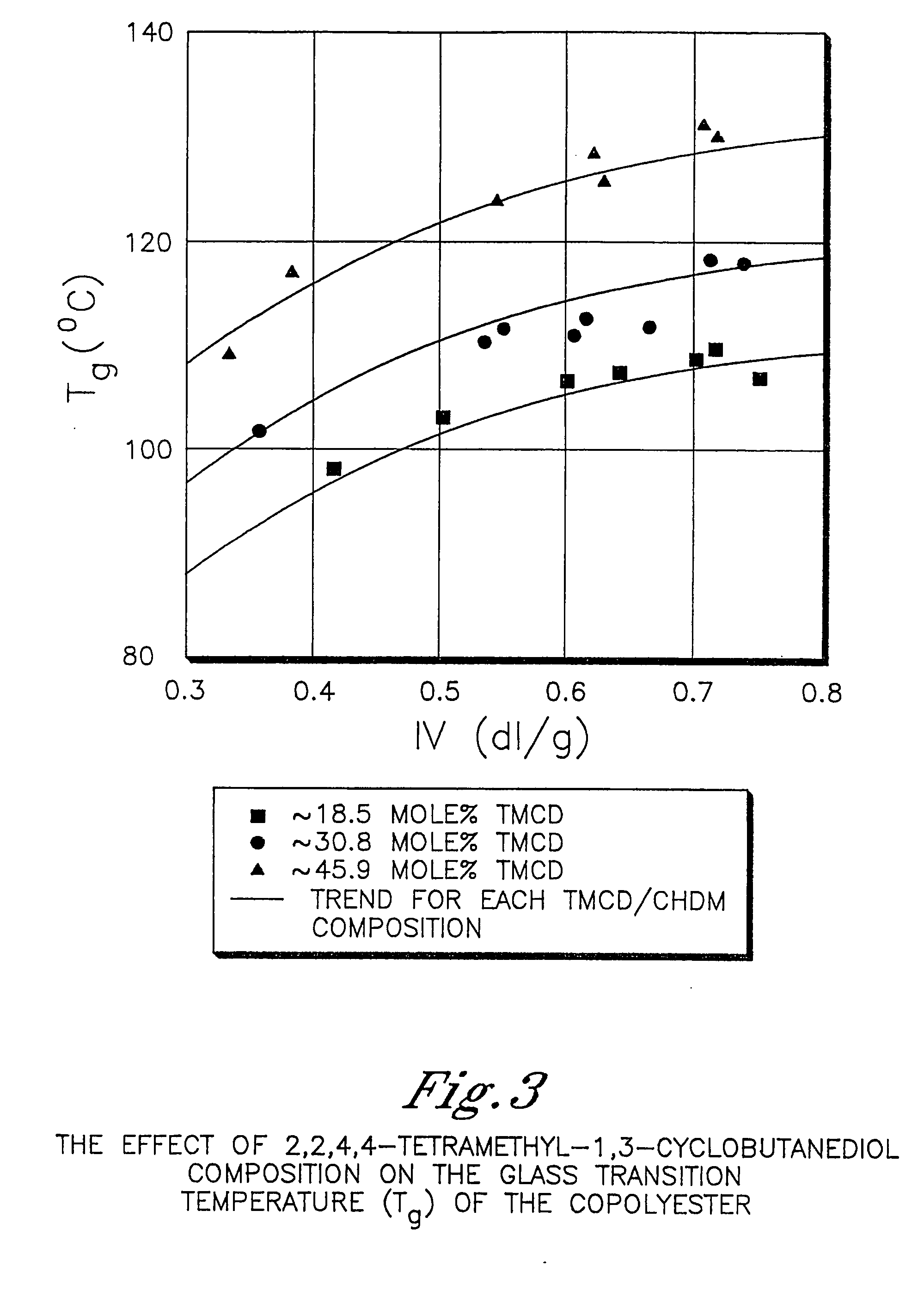

[0192] This example illustrates that 2,2,4,4-tetramethyl-1,3-cyclobutanediol is more effective at reducing the crystallization rate of PCT than ethylene glycol or isophthalic acid. In addition, this example illustrates the benefits of 2,2,4,4-tetramethyl-1,3-cyclobutanediol on the glass transition temperature and density.

[0193] A variety of copolyesters were prepared as described below. These copolyesters were all made with 200 ppm dibutyl tin oxide as the catalyst in order to minimize the effect of catalyst type and concentration on nucleation during crystallization studies. The cis / trans ratio of the 1,4-cyclohexanedimethanol was 31 / 69 while the cis / trans ratio of the 2,2,4,4-tetramethyl-1,3-cyclobutanediol is reported in Table 1.

[0194] For purposes of this example, the samples had sufficiently similar inherent viscosities thereby effectively eliminating this as a variable in the crystallization rate measurements.

[0195] Crystallization half-time measurements from the melt were ...

example 1a

[0199] This example illustrates the preparation of a copolyester with a target composition of 80 mol % dimethyl terephthalate residues, 20 mol % dimethyl isophthalate residues, and 100 mol % 1,4-cyclohexanedimethanol residues (28 / 72 cis / trans).

[0200] A mixture of 56.63 g of dimethyl terephthalate, 55.2 g of 1,4-cyclohexanedimethanol, 14.16 g of dimethyl isophthalate, and 0.0419 g of dibutyl tin oxide was placed in a 500-milliliter flask equipped with an inlet for nitrogen, a metal stirrer, and a short distillation column. The flask was placed in a Wood's metal bath already heated to 210° C. The stirring speed was set to 200 RPM throughout the experiment. The contents of the flask were heated at 210° C. for 5 minutes and then the temperature was gradually increased to 290° C. over 30 minutes. The reaction mixture was held at 290° C. for 60 minutes and then vacuum was gradually applied over the next 5 minutes until the pressure inside the flask reached 100 mm of Hg. The pressure insi...

example 1b

[0201] This example illustrates the preparation of a copolyester with a target composition of 100 mol % dimethyl terephthalate residues, 20 mol % ethylene glycol residues, and 80 mol % 1,4-cyclohexanedimethanol residues (32 / 68 cis / trans).

[0202] A mixture of 77.68 g of dimethyl terephthalate, 50.77 g of 1,4-cyclohexanedimethanol, 27.81 g of ethylene glycol, and 0.0433 g of dibutyl tin oxide was placed in a 500-milliliter flask equipped with an inlet for nitrogen, a metal stirrer, and a short distillation column. The flask was placed in a Wood's metal bath already heated to 200° C. The stirring speed was set to 200 RPM throughout the experiment. The contents of the flask were heated at 200° C. for 60 minutes and then the temperature was gradually increased to 210° C. over 5 minutes. The reaction mixture was held at 210° C. for 120 minutes and then heated up to 280° C. in 30 minutes. Once at 280° C., vacuum was gradually applied over the next 5 minutes until the pressure inside the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com