Sample mounts for microcrystal crystallography

a microcrystal and crystallography technology, applied in the direction of radiation beam directing means, optical radiation measurement, supporters, etc., can solve the problems of reducing the total area of polyimide, reducing fluid resistance and flow disturbance, etc., and achieves excellent mechanical properties, low density, and low atomic number elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

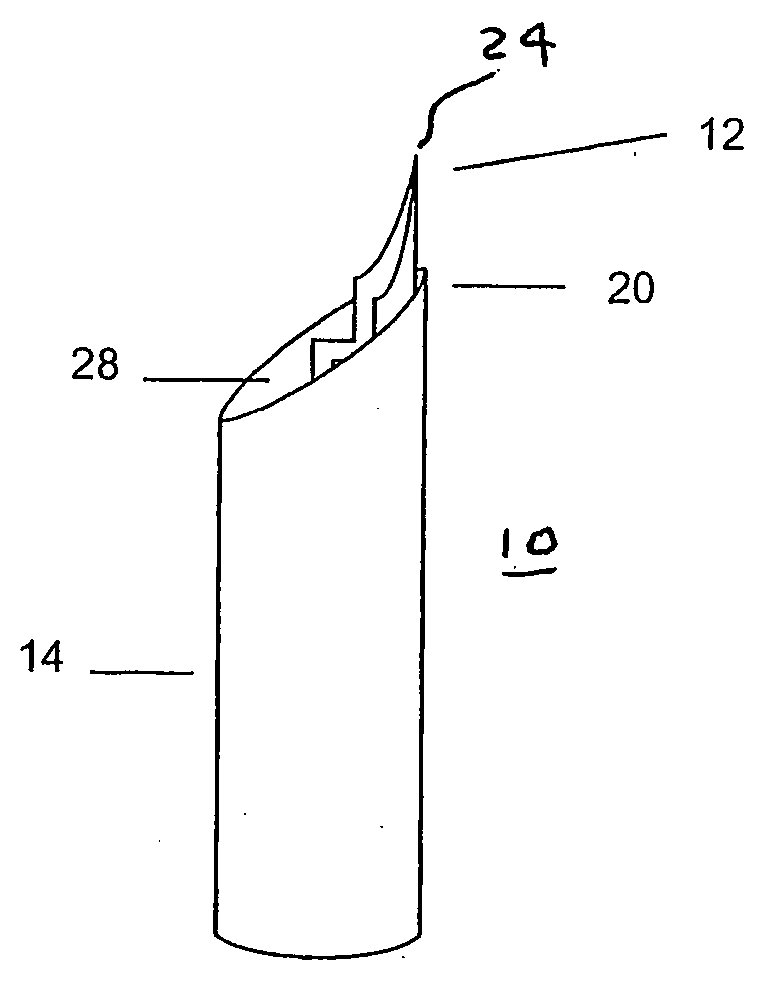

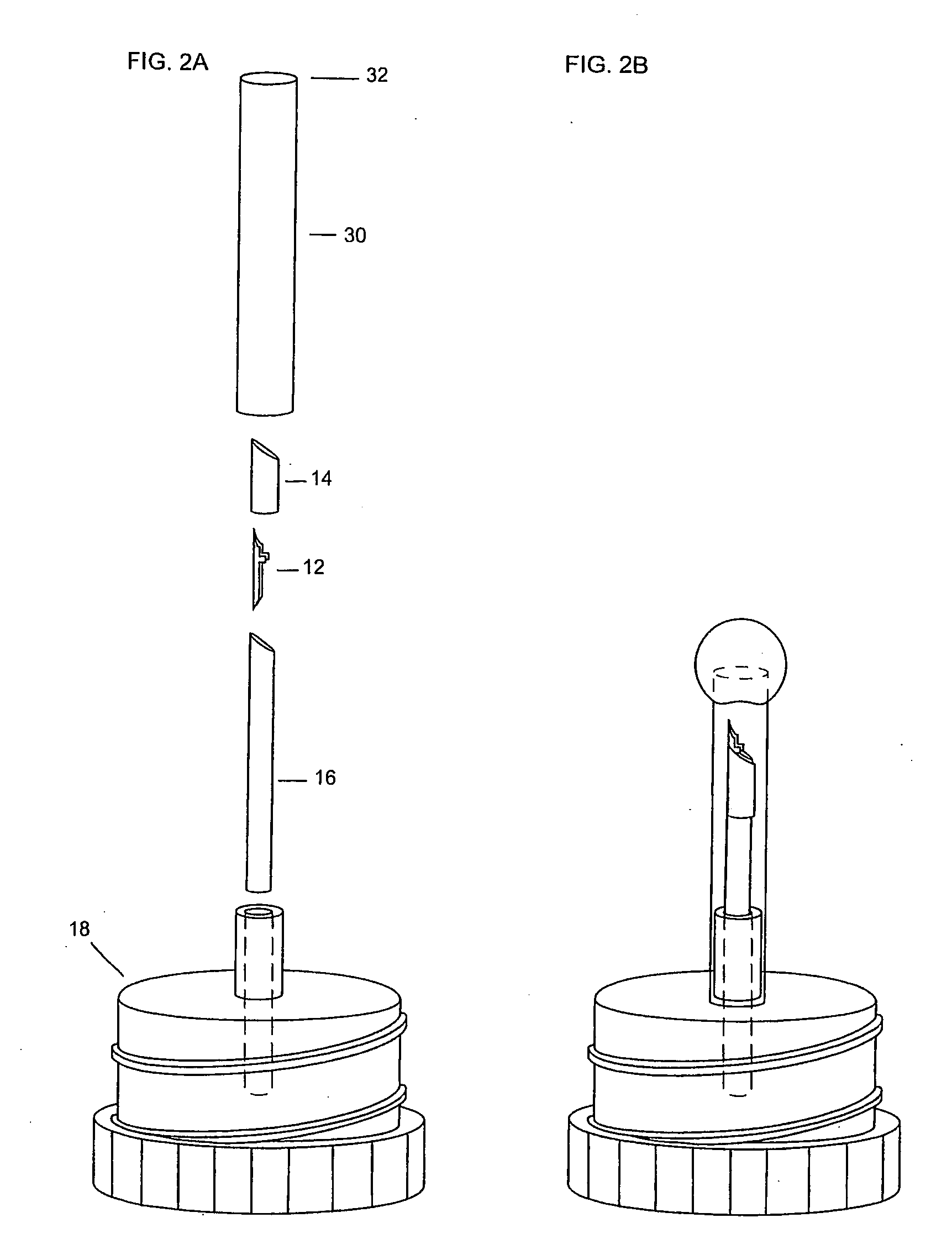

[0029] With reference to FIGS. 1A-1D, several variations of a microcrystal mount 10 are illustrated that are constructed in accordance with four preferred embodiments of the invention and are each designed particularly for use with a goniometer or other standard sample holder / positioner used in X-ray crystallography. In each embodiment, the mount 10 includes a microfabricated plastic film 12 that is attached to a structure having a curved surface such that curvature is imparted to the film 12. In the embodiment of FIG. 1A, the film 12 is attached by any suitable means, such as adhesive, tape, thermal bonding or the like, to a small diameter cylindrical plastic or metal post 16. As illustrated in FIG. 2A, the post 16 is sized to be inserted into standard plastic or metal magnetic goniometer head mount 18, such as those sold by Hampton Research or being developed by the macromolecular crystallography community for high-throughput automated crystallography, or into keyed variants of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com