Semiconductor device comprising light-emitting element and light-receiving element, and manufacturing method therefor

a technology of light-emitting elements and semiconductor devices, which is applied in the direction of basic electric elements, color television, television systems, etc., can solve the problems of increasing the thickness of the packaged semiconductor device, difficult to achieve a reduction in size, and the packaging method using ceramic headers is also problematic, so as to prevent short circuiting of the wiring pattern due to external shocks and the like, reduce the size, and reduce the effect of siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0087] [Structure]

[0088] The structure of a semiconductor device according to a second embodiment of the present invention will now be described using FIGS. 11 and 12.

[0089]FIG. 11 is a plan view of the semiconductor device according to the second embodiment of the present invention, and FIG. 12 is a sectional view along A-A in FIG. 11.

[0090] As shown in FIGS. 11 and 12, the semiconductor device according to the second embodiment of the present invention includes a transparent substrate 1210, a wiring layer 1220, a bump electrode 1230, a semiconductor chip 1240, a columnar electrode 1250, a sealant 1260, an external connection terminal 1270, a lens portion 1280, and a cut surface 1290. Detailed description of constitutional parts that are identical to the first embodiment has been omitted.

[0091] The transparent substrate 1210 comprises a rectangular first face 1211 having a first central region 1211a and a first peripheral region 1211b surrounding the first central region 1211a, ...

third embodiment

[0108] [Structure]

[0109] The structure of a semiconductor device according to a third embodiment of the present invention will now be described using FIGS. 19 and 20.

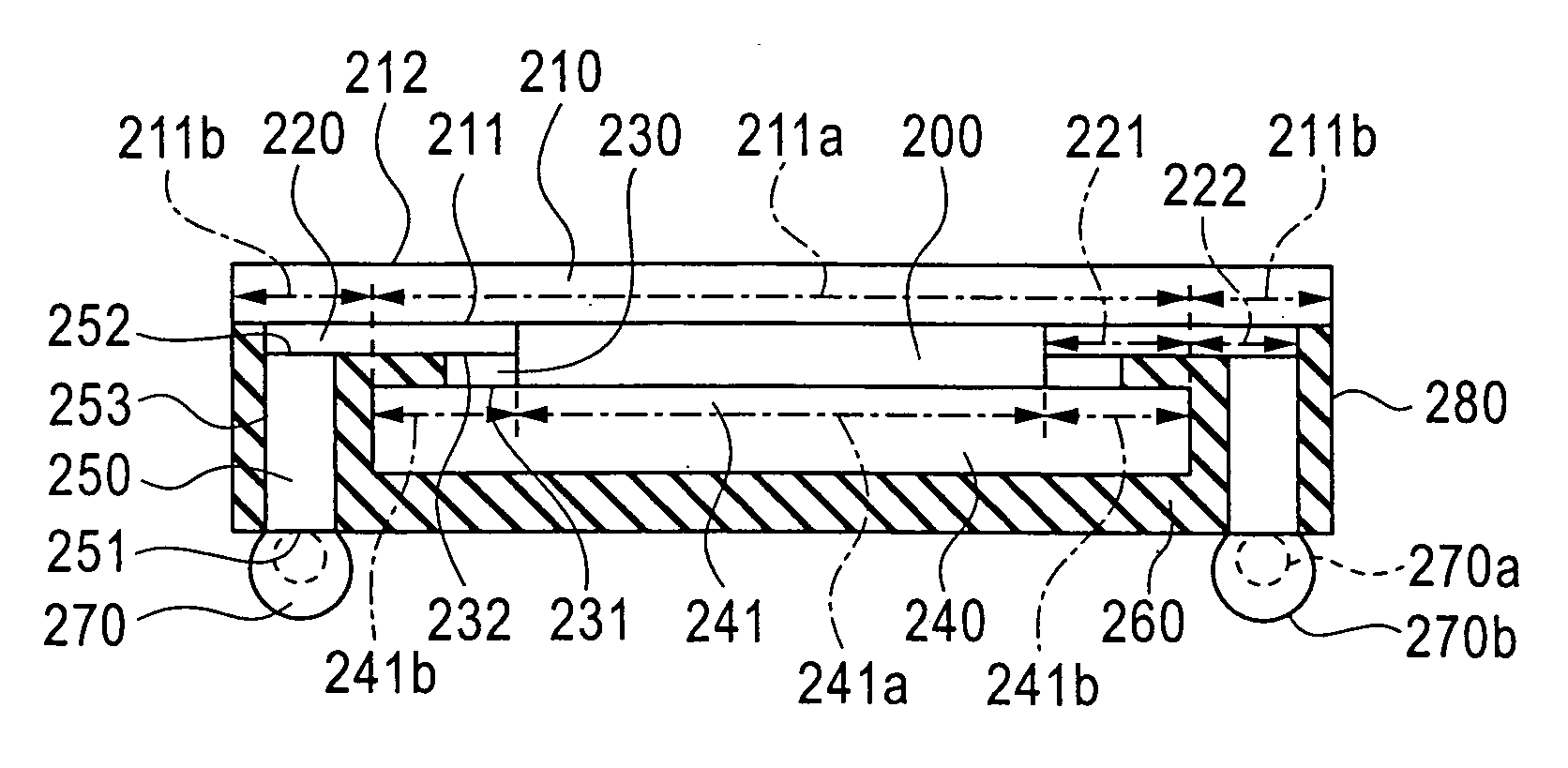

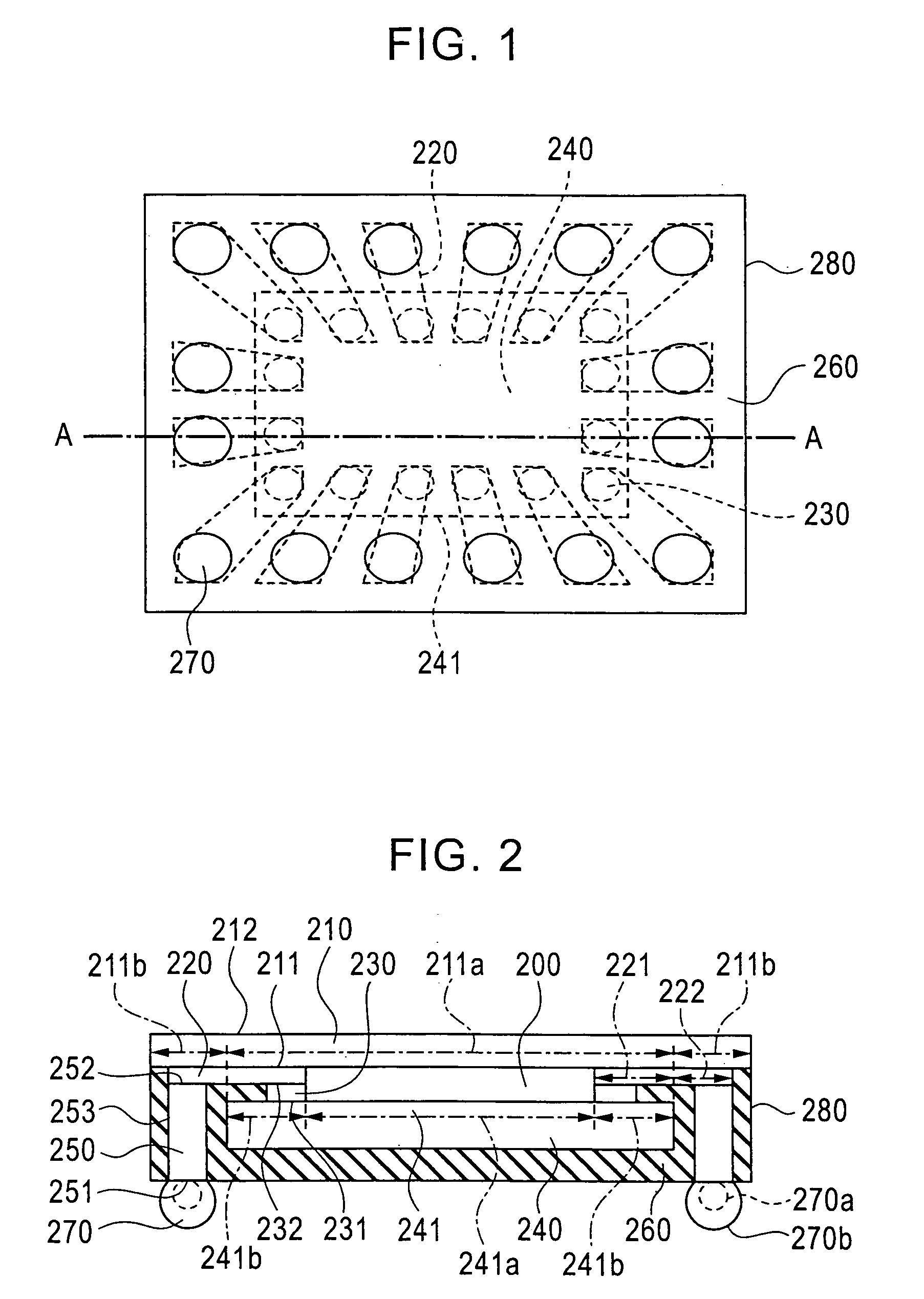

[0110]FIG. 19 is a plan view of the semiconductor device according to the third embodiment of the present invention, and FIG. 20 is a sectional view along A-A in FIG. 19.

[0111] As shown in FIGS. 19 and 20, the semiconductor device according to the third embodiment of the present invention includes a transparent substrate 2010, a wiring layer 2020, a bump electrode 2030, a semiconductor chip 2040, a columnar electrode 2050, a sealant 2060, an external connection terminal 2070, a lens portion 2080 formed on the transparent substrate 2010, and a cut surface 2090. Detailed description of constitutional parts that are identical to the first embodiment has been omitted.

[0112] The transparent substrate 2010 comprises a rectangular first face 2011 having a central region 2011a and a peripheral region 2011b surrounding the ce...

fourth embodiment

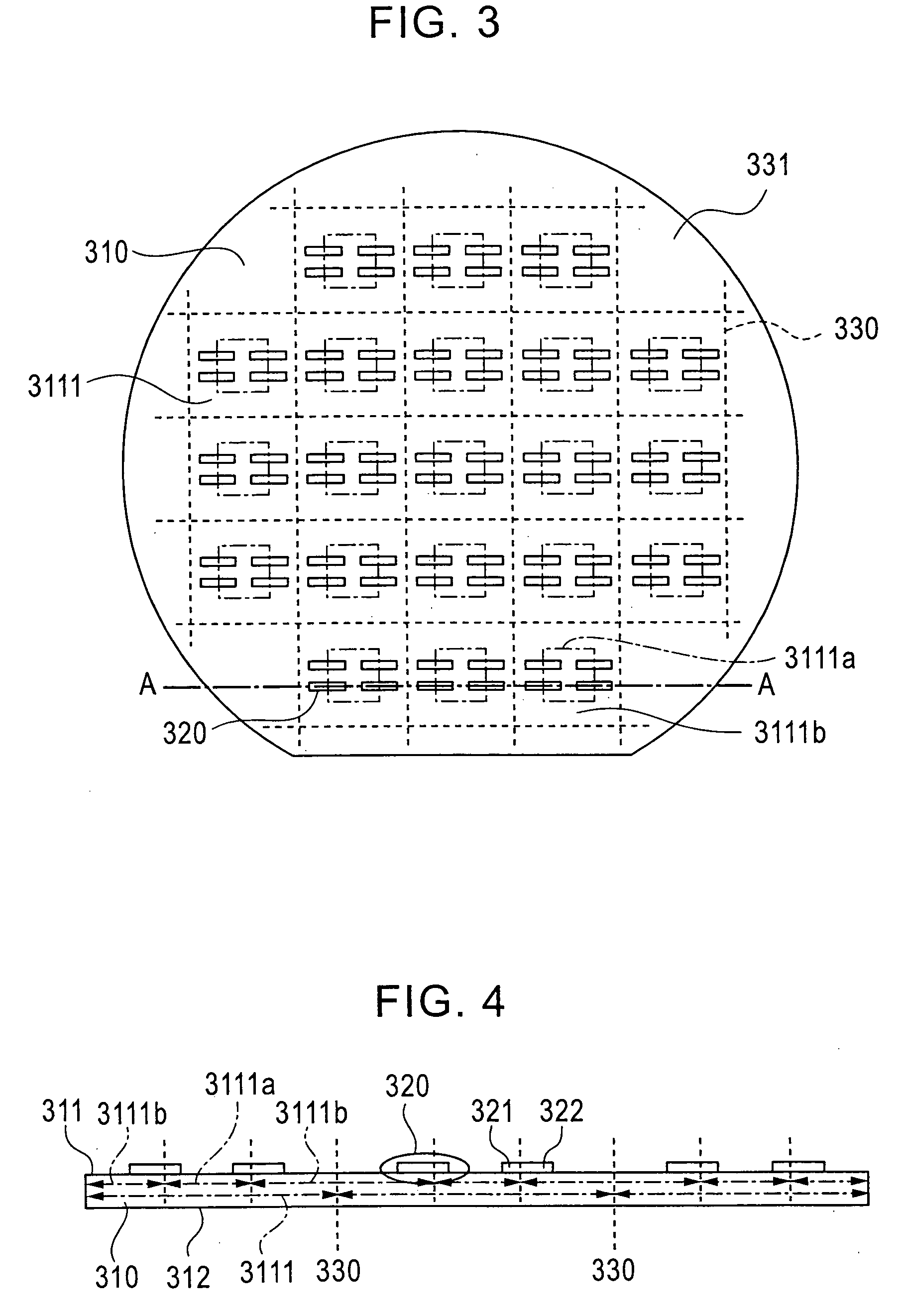

[0122] The structure of a semiconductor device according to a fourth embodiment of the present invention will now be described using FIGS. 25 and 26.

[0123]FIG. 25 is a plan view of the semiconductor device according to the fourth embodiment of the present invention, and FIG. 26 is a sectional view along A-A in FIG. 25.

[0124] As shown in FIGS. 25 and 26, the semiconductor device according to the fourth embodiment of the present invention includes a transparent substrate 2610, a first wiring layer 2620, a second wiring layer 2621, a third wiring layer 2622, a first bump electrode 2630, a second bump electrode 2631, a third bump electrode 2632, a fourth bump electrode 2633, a first semiconductor chip 2640, a second semiconductor chip 2650, a first columnar electrode 2660, a second columnar electrode 2670, a sealant 2680, a first external connection terminal 2690, a second external connection terminal 2691, and a cut surface 2510.

[0125] The transparent substrate 2610 comprises a rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com