High efficiency peptide production in plant cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production of Antigenic Peptides in CCMV Virus Particles in Whole Cowpea Plants Inoculated with CCMV RNA1, RNA2, and Chimeric RNA3

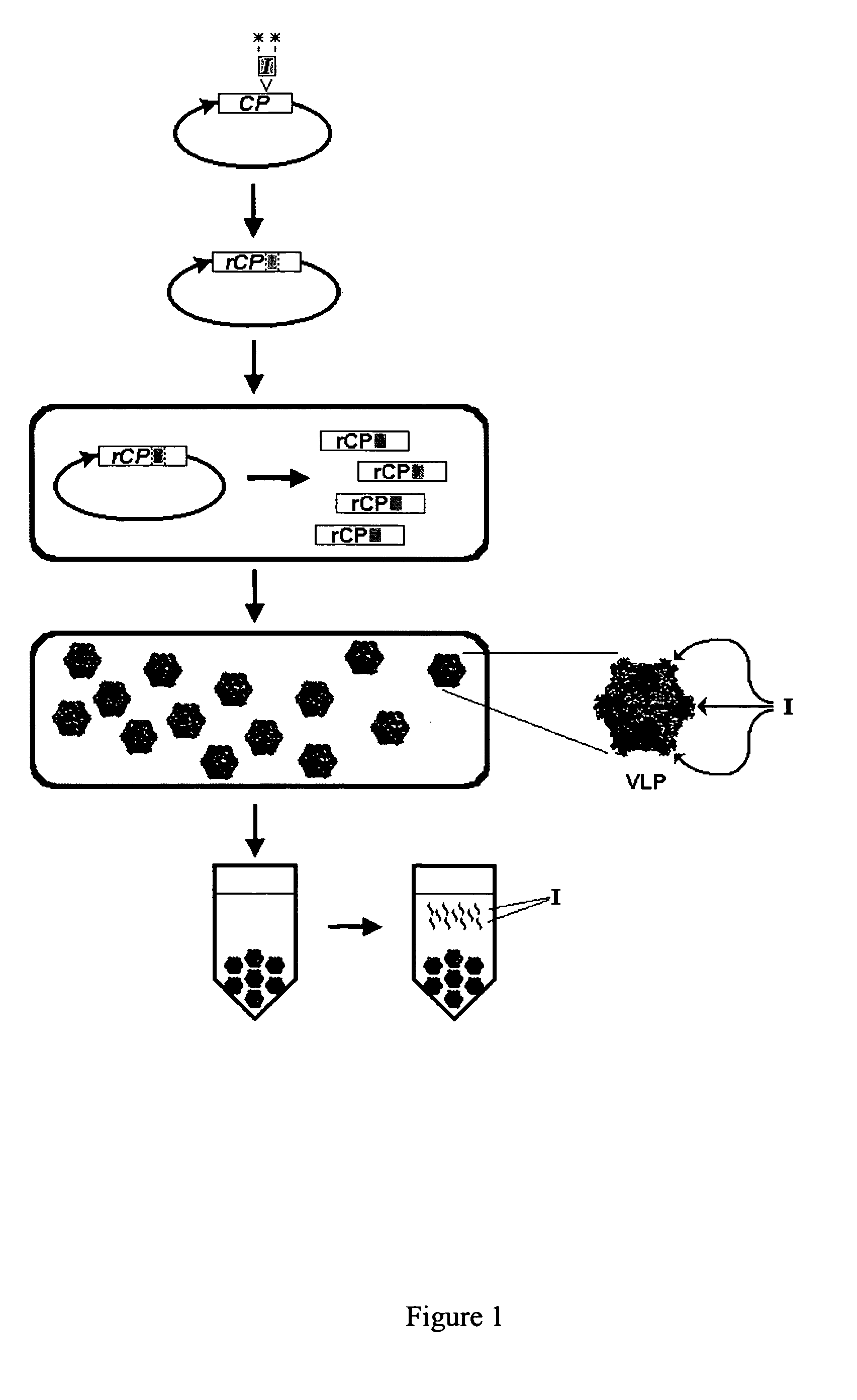

[0211] Expression of Bacillus anthracis antigenic peptides was performed in whole plants, using cowpea chlorotic mottle virus (CCMV) with capsid proteins (CP) engineered to contain one of four different antigenic peptides.

[0212] DNA having the nucleotide sequence of CCMV RNA 1 and DNA having the nucleotide sequence of CCMV RNA 2 were each separately subcloned in the cloning vector pUC19 downstream from, and under the control of, a T7 promoter and upstream from a unique Xba I site. This produced plasmids pDOW2122 (CCMV RNA1) and pDOW2123 (CCMV RNA2).

[0213] DNA having the nucleotide sequence of CCMV RNA 3, engineered to contain five BamH I restriction enzyme cleavage sites, was further engineered for production of the recombinant capsid protein-encoding nucleic acid. Four DNA molecules, each encoding a different one of four exogenous peptides (four diffe...

example 2

Production of Antigenic Peptides in CCMV Virus Particles in Tobacco Suspension Culture Inoculated with CCMV RNA1, RNA2, and Chimeric RNA3

[0220] Expression of the same CCMV-peptide-encoding constructs was performed in plant cell suspension culture. Nicotiana tabacum NT1 cells were transfected by electroporation with RNA transcripts of CCMV RNA 3 coding for the chimeric CCMV coat proteins and CCMV RNA 1 and 2 coding for the replicase genes. Wild-type CCMV coat protein-encoding RNA 3 and engineered CCMV coat protein-encoding RNA 3 containing the appropriate BamHI restriction site but no inserts were used as controls.

[0221] 24 different RNA varieties were obtained by in vitro RNA transcription as described in the Example 1: one for RNA1, one for RNA2, 20 for chimeric RNA3, and two for RNA3 controls. In 22 different groups, two micrograms of each of three resulting RNAs (RNA1, RNA2, and one of the RNA3s) were transformed into tobacco cells by electroporation.

The Following Protocol wa...

example 3

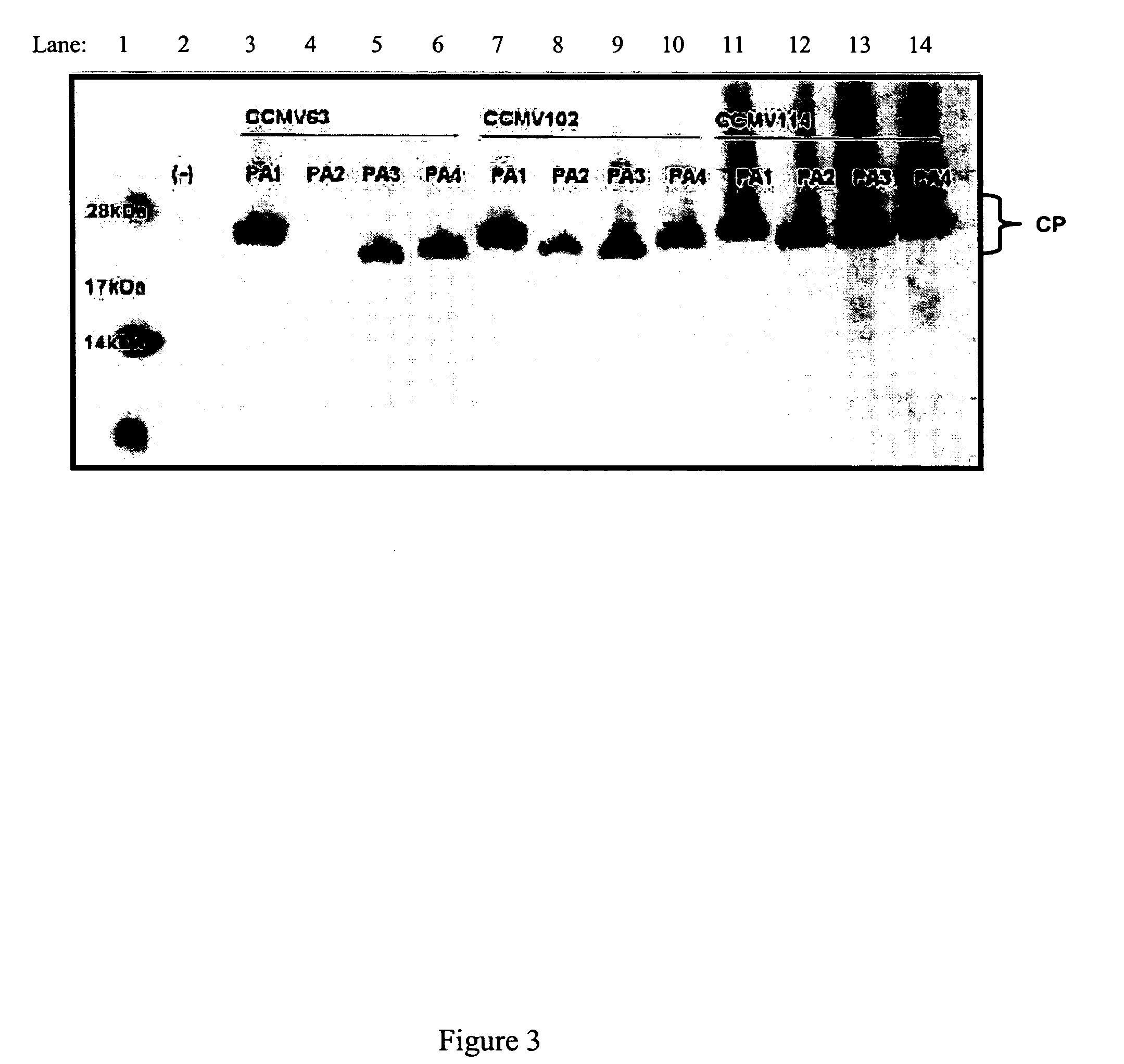

Production of 4 Antigenic Peptides in CCMV Virus-like Particles in Tobacco Suspension Culture Transfected with Plant Expression Plasmids Encoding the Chimeric CCMV CPs

[0239] 1) Vector Construction:

[0240] Plasmid pIL-Tab358 was used as the plant expression vector. Restriction sites chosen for CCMV CP insertion were XbaI and EcoRI. This plasmid contains the Cassava Vein Mosaic Virus promoter upstream of the XbaI site and a Nos terminator downstream of the EcoRI site. The vector was prepared by digestion with XbaI and EcoRI and dephosphorylated before litigation with the inserts.

[0241] 2) Insert Construction:

[0242] CCMV CP-PA fusions were amplified by PCR out of pDOW2147 (PUC-CCMV-RNA3-CP129BamHI-PA1), pDOW2148 (pUC-CCMV-RNA3-CP129BamHI-PA2), pDOW2149 (pUC-CCMV-RNA3-CP 129BamHI-PA3), pDOW2150 (pUC-CCMV-RNA3-CP 129BamHI-PA4) using primers CCMV-CP-XbaI (SEQ ID NO:22) and CCMV-CP-EcoRI (SEQ ID NO: 23) to create pDOW2160 (pIL-Tab-CCMV129BamHI-PA1) (SEQ ID NO: 5), pDOW2161 (pIL-Tab-CCMV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Antigenicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com