Droplet ejecting apparatus, electro-optic device, electronic apparatus, and droplet ejecting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0060] A droplet ejecting apparatus, an electro-optic device, and an electronic apparatus according to preferred embodiments of the present invention will be described in detail below.

(Droplet Ejecting Apparatus)

[0061] A droplet ejecting apparatus according an embodiment of the present invention will be described in detail below in the order of “Whole configuration of droplet ejecting apparatus”, “Carriage”, “Head”, “Head group”, “Control unit”, “Ejection method”, “Modified example of ejection method”, and “Modified example of head arrangement”.

(Whole Configuration of Droplet Ejecting Apparatus)

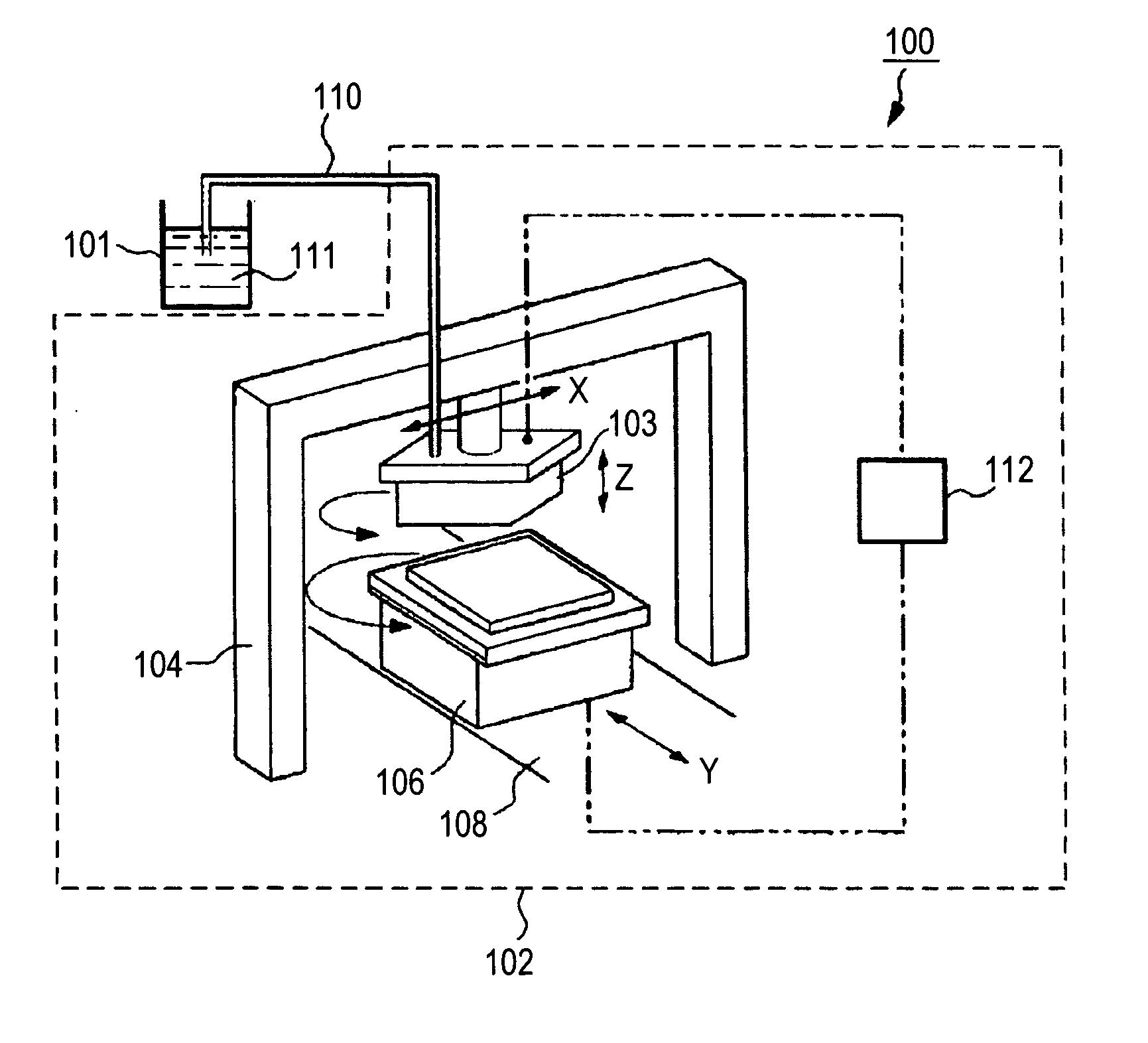

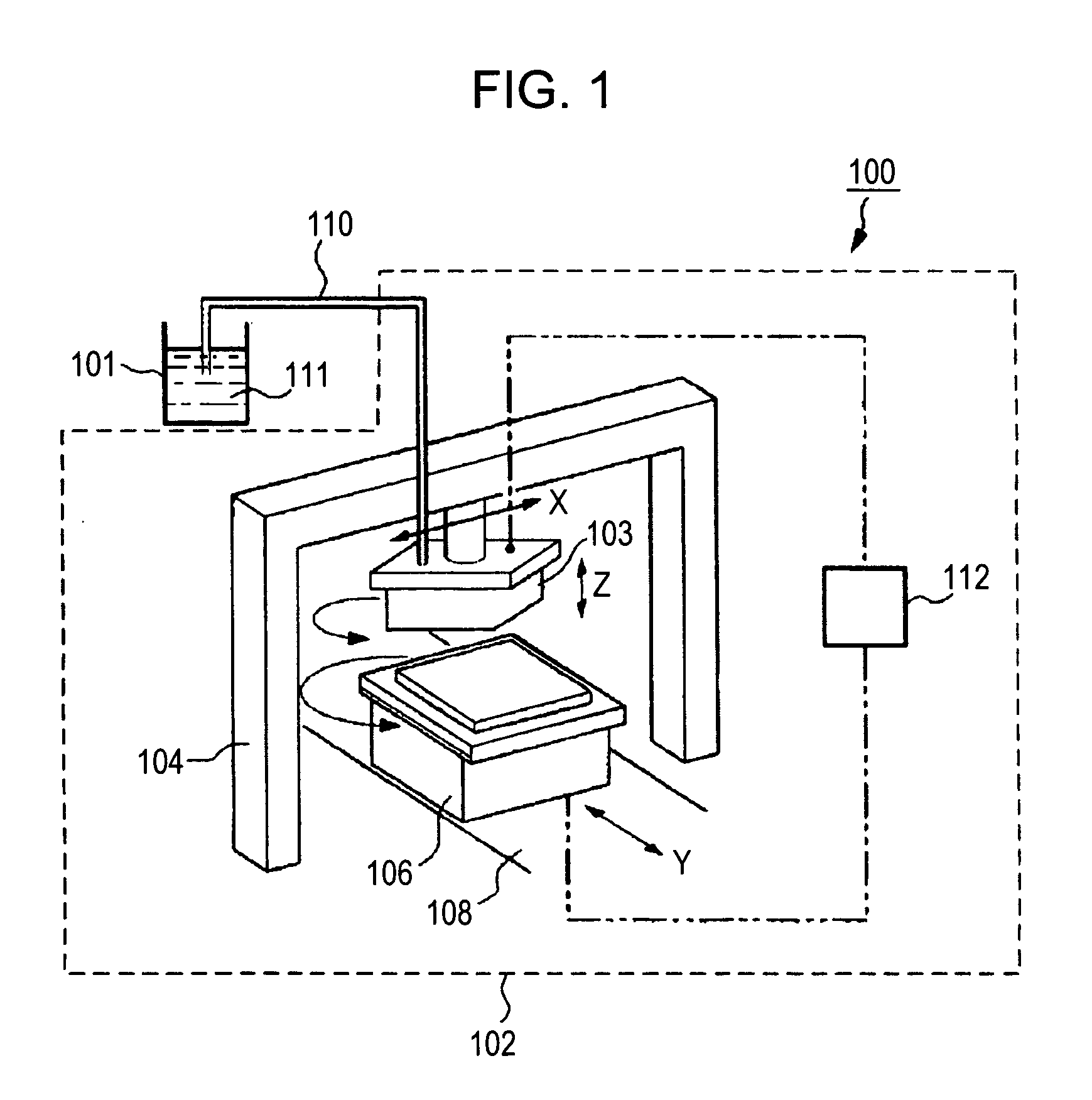

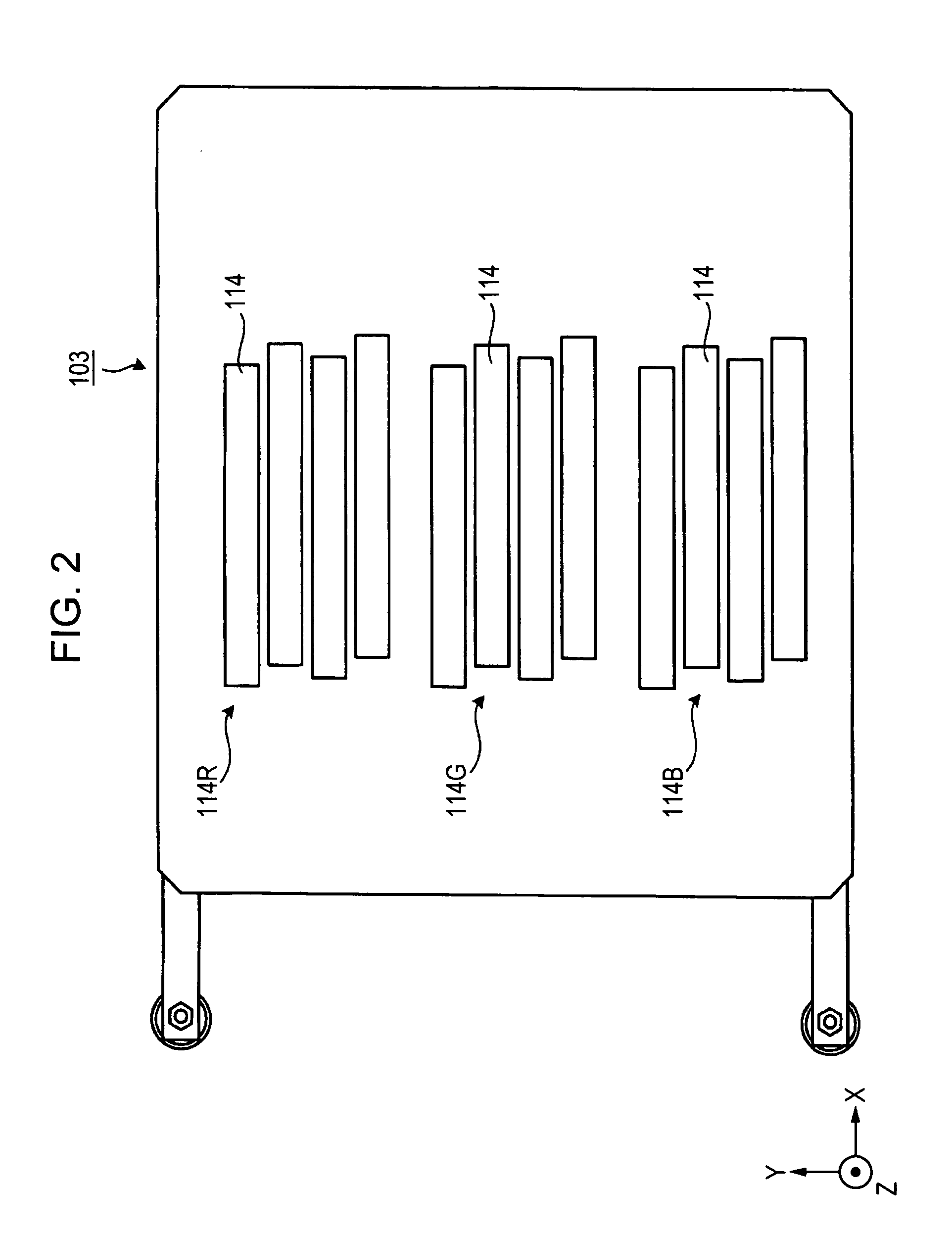

[0062] As shown in FIG. 1, a droplet ejecting apparatus 100 comprises a tank 101 holding a liquid material 111, a tube 110, and an ejection scanning unit 102 to which the liquid material 111 is supplied from the tank 101 through the tube 110. The ejection scanning unit 102 comprises a carriage 103 holding a plurality of heads 114 (FIG. 2), a first position control device 104 for control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com