Portable no-pump multi-fuel stove

a multi-fuel stove, portable technology, applied in the direction of gaseous heating fuel, stoves or ranges, combustion types, etc., can solve the problems of not being suitable for portable stoves, gas stoves with small energy output, and hardly used, and achieves small and light structure, easy separation, and easy exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

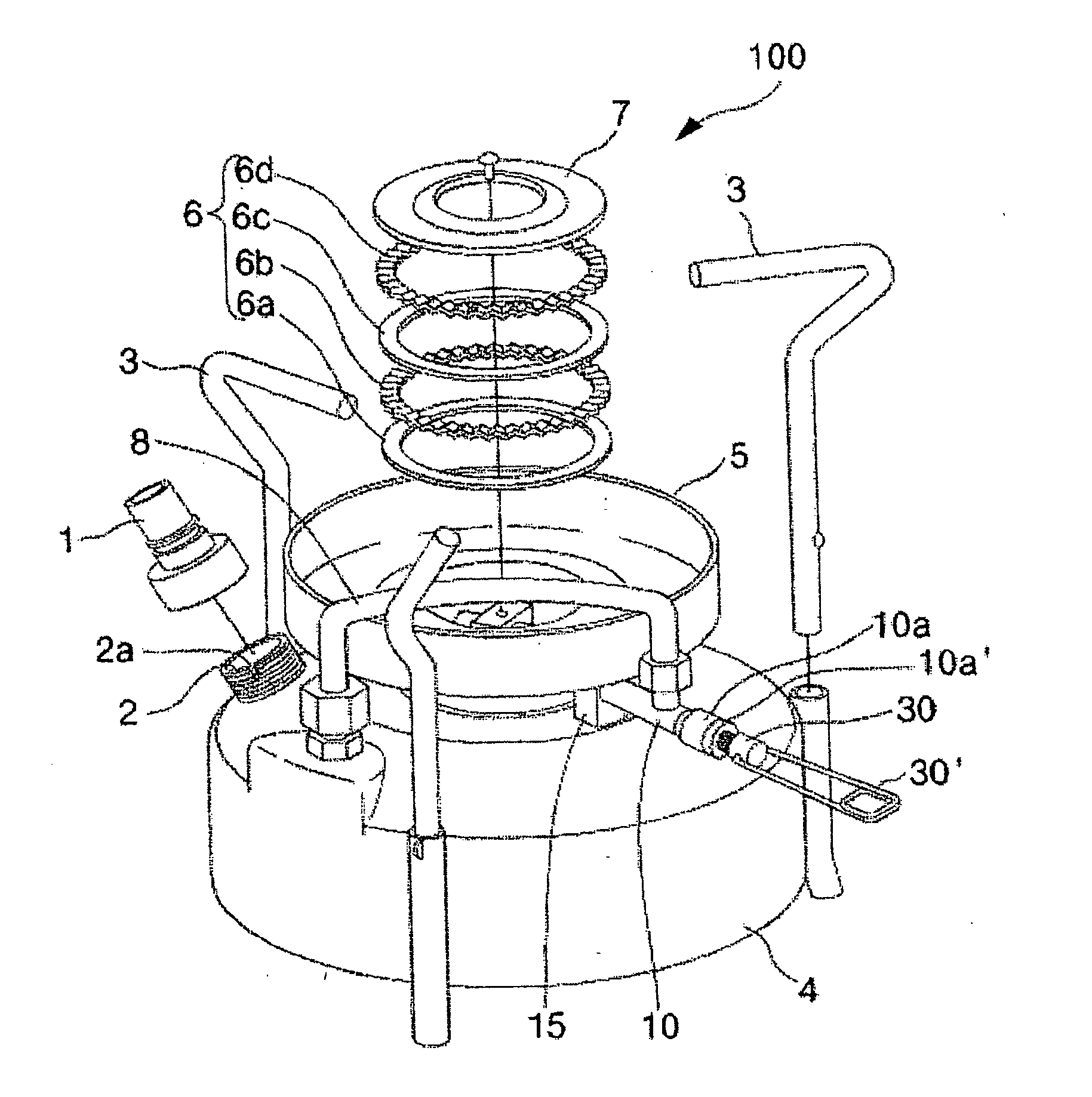

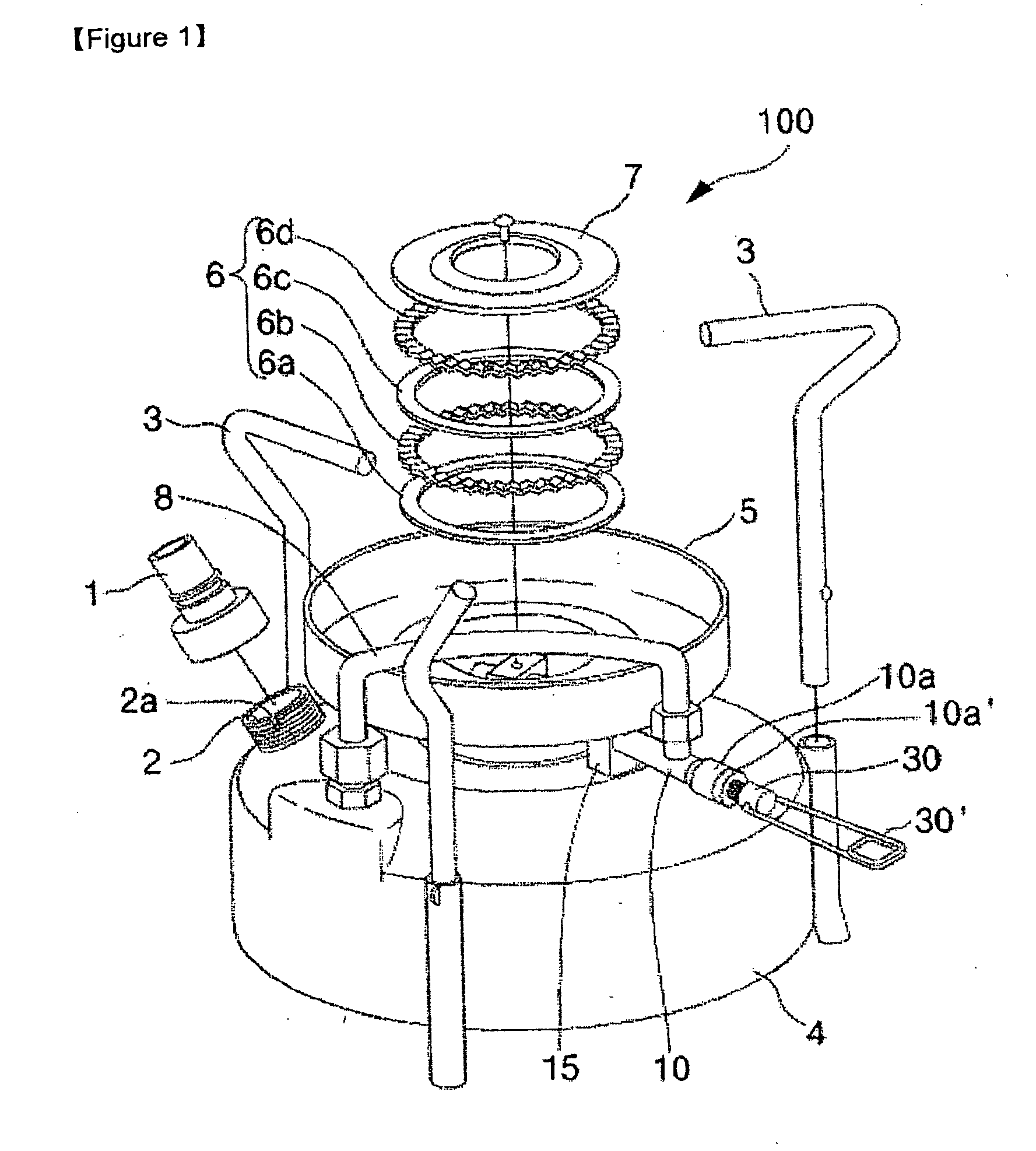

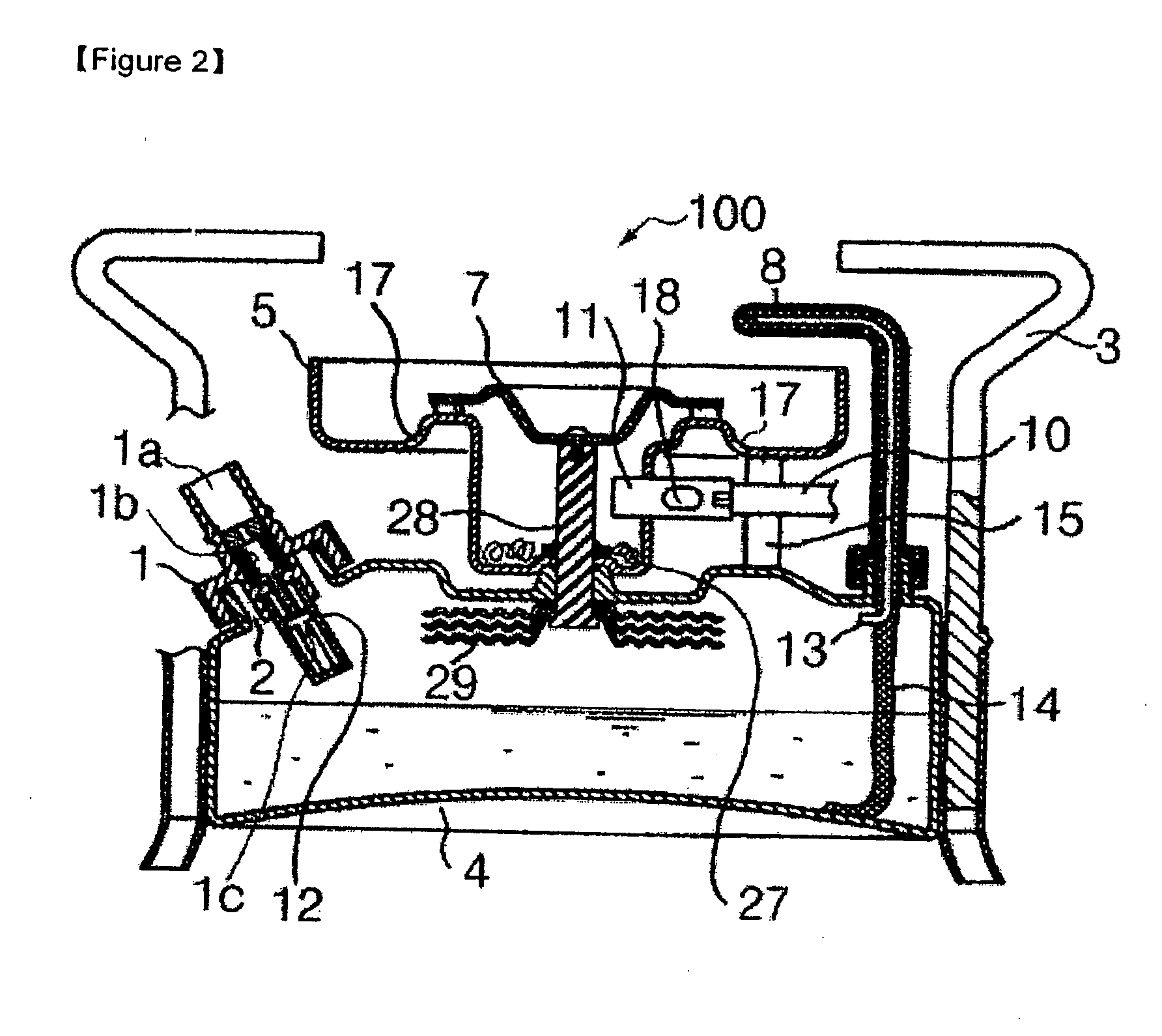

[0042]FIG. 1 is a perspective view showing a stove according to a preferred embodiment of the present invention, FIG. 2 is a longitudinal sectional view of FIG. 1, and FIG. 3 is a front view showing that a flame hole ring with a V-shaped groove and a flat flame hole ring are accumulatively assembled between a burner cap and a burner bowl of the stove shown in FIG. 1.

[0043] As shown in FIGS. 1 to 3, a portable stove 100 using both gasoline and gas according to a preferred embodiment of the present invention is configured so that a burner bowl 5 acting as a windscreen, a flame hole ring 6 where at least one ply of a flat flame hole ring and a flame hole ring with a V-shaped groove are accumulatively assembled, and a burner cap 7 are subsequently assembled to a central upper portion of a fuel tank 4 having a cylindrical shape with a fuel injection hole 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com