Irradiation system and method

a technology of irradiation system and accelerator, which is applied in the direction of cleaning using liquids, instruments, and therapy, can solve the problems of limited maximum energy of electrostatic accelerator, high cost and risk of foodborne illness, and ground beef is of particular concern for foodborne illness risk,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

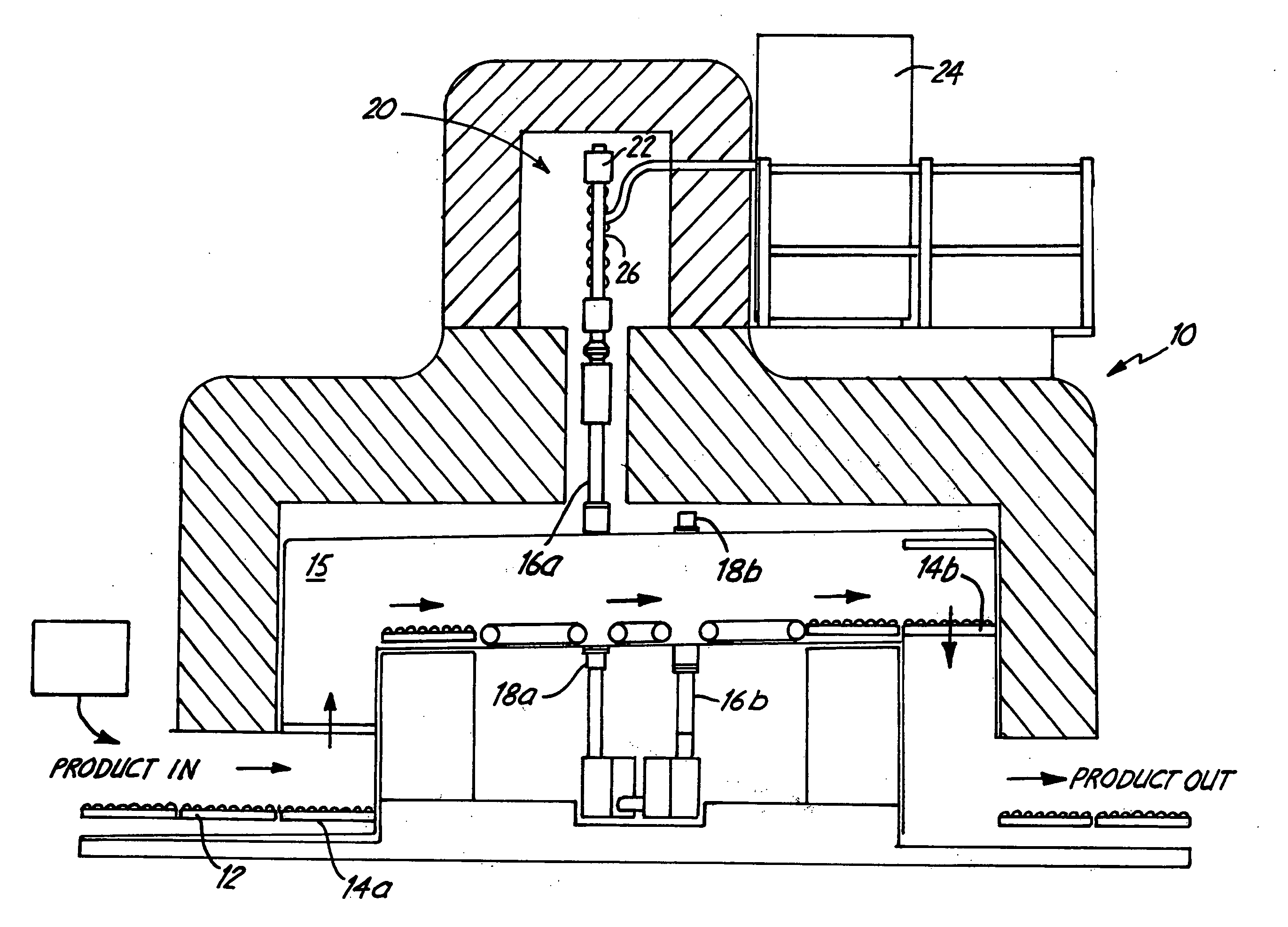

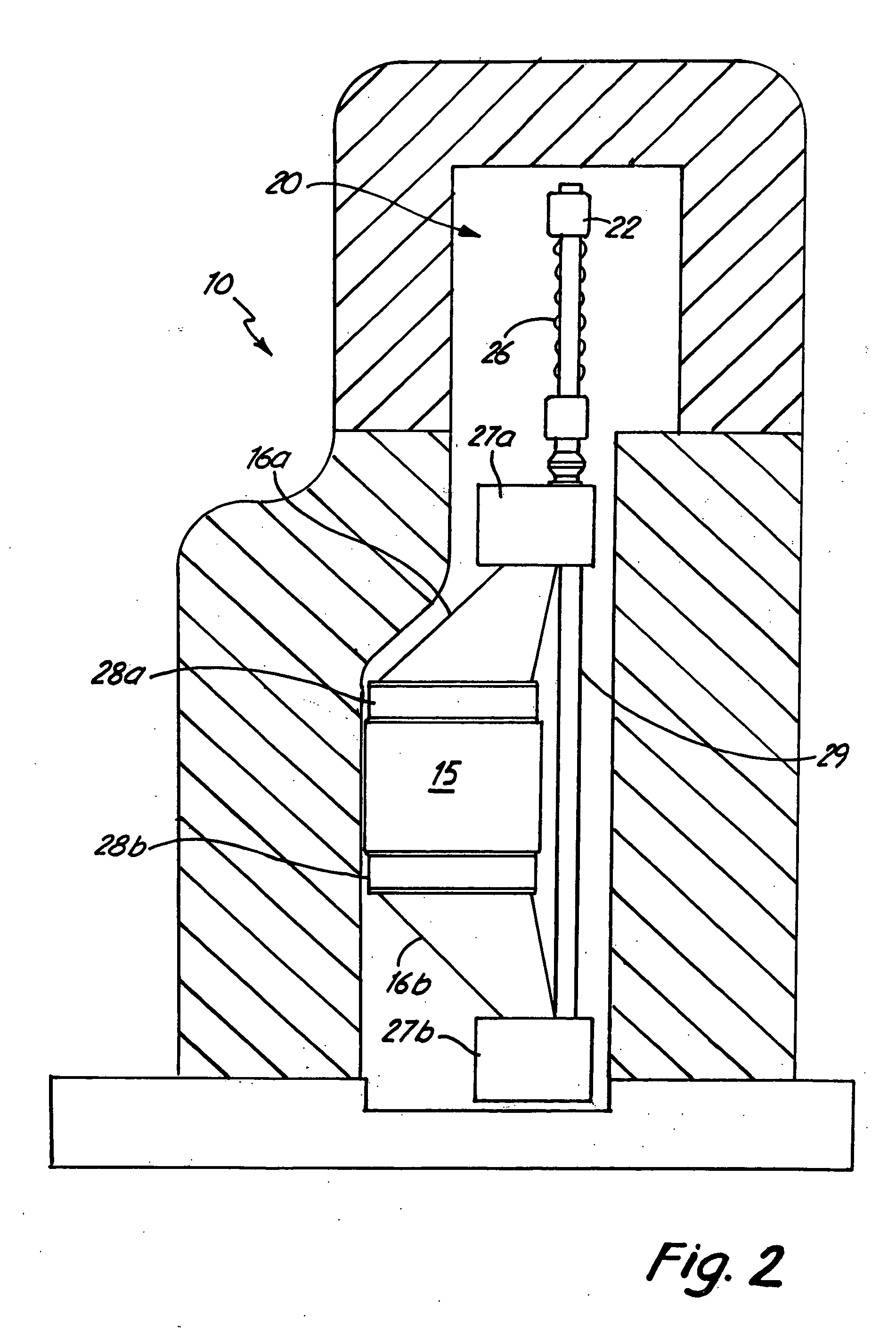

[0040]FIG. 1 is a front section view of irradiation system 10 according to an exemplary embodiment of the present invention. Irradiation system 10 includes product conveyor 12 and elevators 14a and 14b housed within sealed tube 15, scan horns 16a and 16b, optional dose monitors 18a and 18b, and accelerator 20 including electron gun 22, power supply 24 and accelerator waveguide structure 26. Product conveyor 12 is arranged to carry articles to be irradiated at a first elevation in an input portion of irradiation system 10, at a second elevation (due to elevator 14a) in a processing portion of irradiation system 10, and at a third elevation (due to elevator 14b) in an output portion of irradiation system 10. In the exemplary embodiment of FIG. 1, the first and third elevations are the same, but this does not necessarily have to be the case. Sealed tube 15 surrounds product conveyor 12 in all of the portions of irradiation system 10, which has a number of advantageous effects. The inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| static voltage | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| energy levels | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com