Acoustically damped composite construction for the forward portion of a rocket or missile

a composite construction and forward portion technology, applied in the field of acoustically damped composites, can solve the problems of easy damage to satellites or other vibration-sensitive cargo, too rigid to provide shock or vibration damping, and add a great deal of weight and cost to the payload fairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any expressed or implied theory presented in the preceding technical field, background, brief summary or the following detailed description.

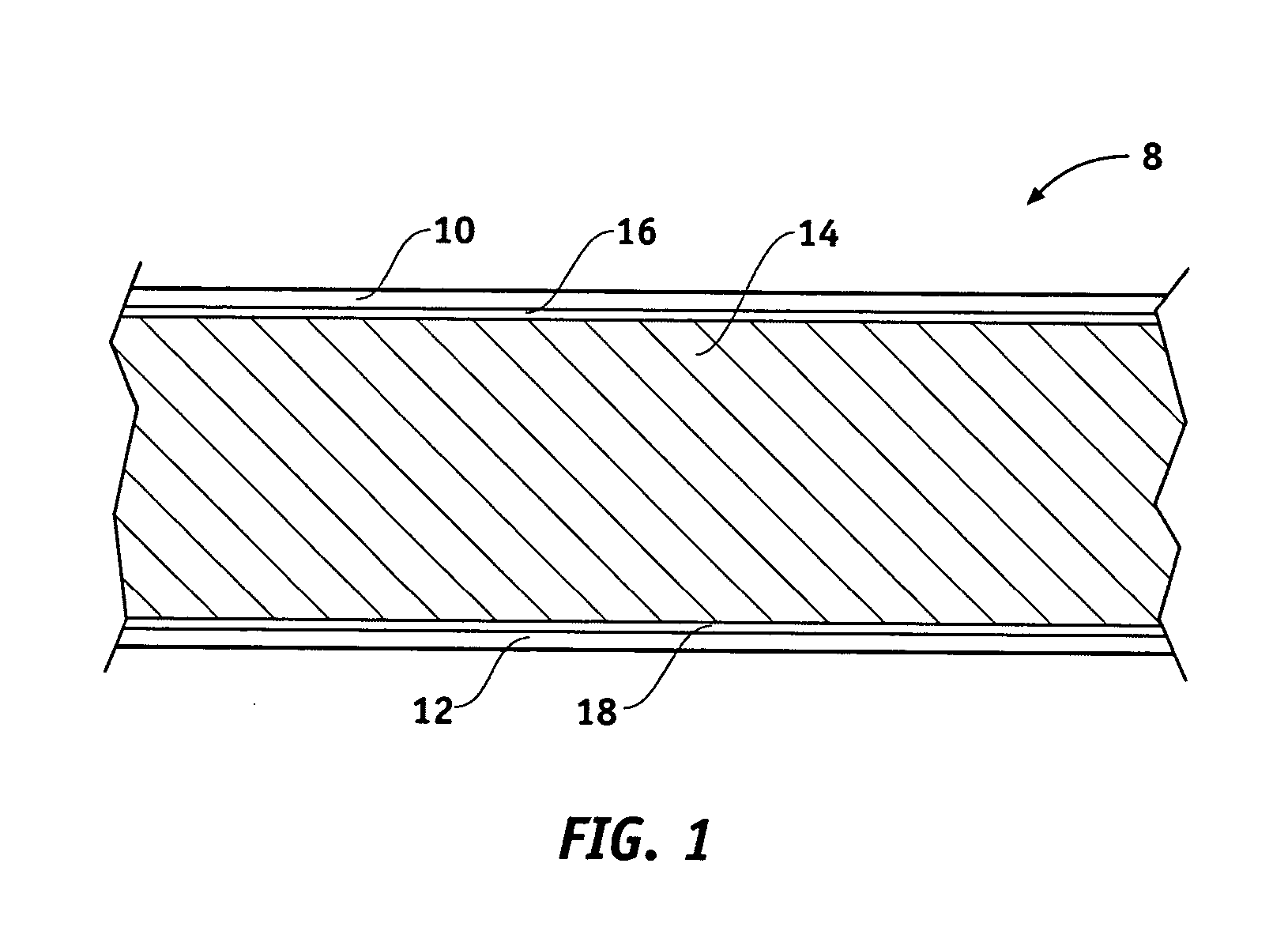

[0008] An acoustically damped composite construction particularly useful in payload fairings incorporates passive means of damping acoustic vibration and shock into the composite construction itself. In accordance with one embodiment of the invention the face sheets of the composite construction are bonded to a lightweight core with a bonding material such as a visco elastic adhesive material. Rather than have the face sheets rigidly bonded to a lightweight core, the visco elastic adhesive allows the face sheets to move slightly relative to each other and to the lightweight core, absorbing acoustic vibration and producing heat as a bypro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com