The present invention is a hand-held microwave system for intra-oral dentistry that utilizes microwave energy to cure polymer materials intra-orally so as to produce dental composites having improved physical characteristics, and also utilizes microwave energy to detect the presence of and to preferentially heat caries or cavities, thereby disinfecting and therapeutically treating the caries in a potentially non-invasive manner. The intra-oral

polymerization process can be accomplished with less overall energy and with composite-matrices that maximally absorb the microwave energy so as to reduce heating of adjacent tissue. The antenna of a hand-held version of the intra-oral microwave system is also advantageously designed to detect the presence of and to preferentially heat caries or cavities, thereby disinfecting and therapeutically treating the caries in a potentially non-invasive manner.

The hand-held dental tool is designed to apply continuous microwave energy in accordance for use in creating dental composites directly in a patient's mouth.

Microwave energy having a frequency of between 1 GHz to 50 GHz, and preferably between 14 GHz to 24 GHz, is applied by an antenna at the distal end of the hand-held tool which is connected via a conductor or wave guide to a microwave generator that supplies low power microwave energy in response to precisely controlled voltages. Preferably, the microwave energy power is less than about 10 W and ideally between 3 W and 5 W and the control voltages operate between 12 V and 65 V, depending upon the desired

curing time and the particular composition of the

resin matrix to be cured. Preferably, the antenna and distal end of the hand-held tool are structured to enable the operator to exert some degree of pressure on the composite resin-matrix in the mouth while it is being cured by the application of microwave energy. The low power microwave energy provided by the hand-held tool of this embodiment is safe for intermittent

human exposure as the power and frequency ranges emitted by the antenna are similar to that emitted by cellular telephones.

One of the advantages of the hand-held dental tool is that it can also serve as a tool for non-invasively detecting and / or treating caries or cavities. Carious

tooth tissue consists of demineralized and softened and moist

tooth enamel or

dentin, and contains micro-organisms. If the carious tooth tissue has not degraded to the point where the physical properties of the tooth are compromised, it is possible for the carious tooth tissue to recalcify and reharden if the micro-organisms causing the carious tooth tissue can be killed and the tooth can be kept under aseptic conditions. Infected tooth tissue which is not removed or not kept under aseptic conditions will remain as an active carious

lesion, and will continue to cause progressive and destructive loss of tooth tissue. The use of the continuous microwave energy supplied by the hand-held dental tool embodiment of the present invention can eliminate or reduce the infection caused by the micro-organisms as the type of microwave energy is selected to preferentially heat and destroy the micro-organisms in the carious tooth tissue. In some cases, the hand-held dental tool can be used to kill the micro-organisms internal to the tooth tissue by the use of microwave energy and then a

sealant can be applied to the exterior of the tooth which will be sufficient to keep an aseptic environment and promote the recalcification of the underlying tooth tissue. In other cases, portions of the carious tooth tissue may need to be removed and the hand-held tool can be used to kill the micro-organisms both internal to the tooth tissue and on the surface of the cavity. Once the micro-organisms have been destroyed, a polymer

dental composite can be applied to the cavity. The polymer

dental composite is preferably microwave cured using the hand-held dental tool to seal the treated tooth tissue and provide additional physical and structural support for the cavity.

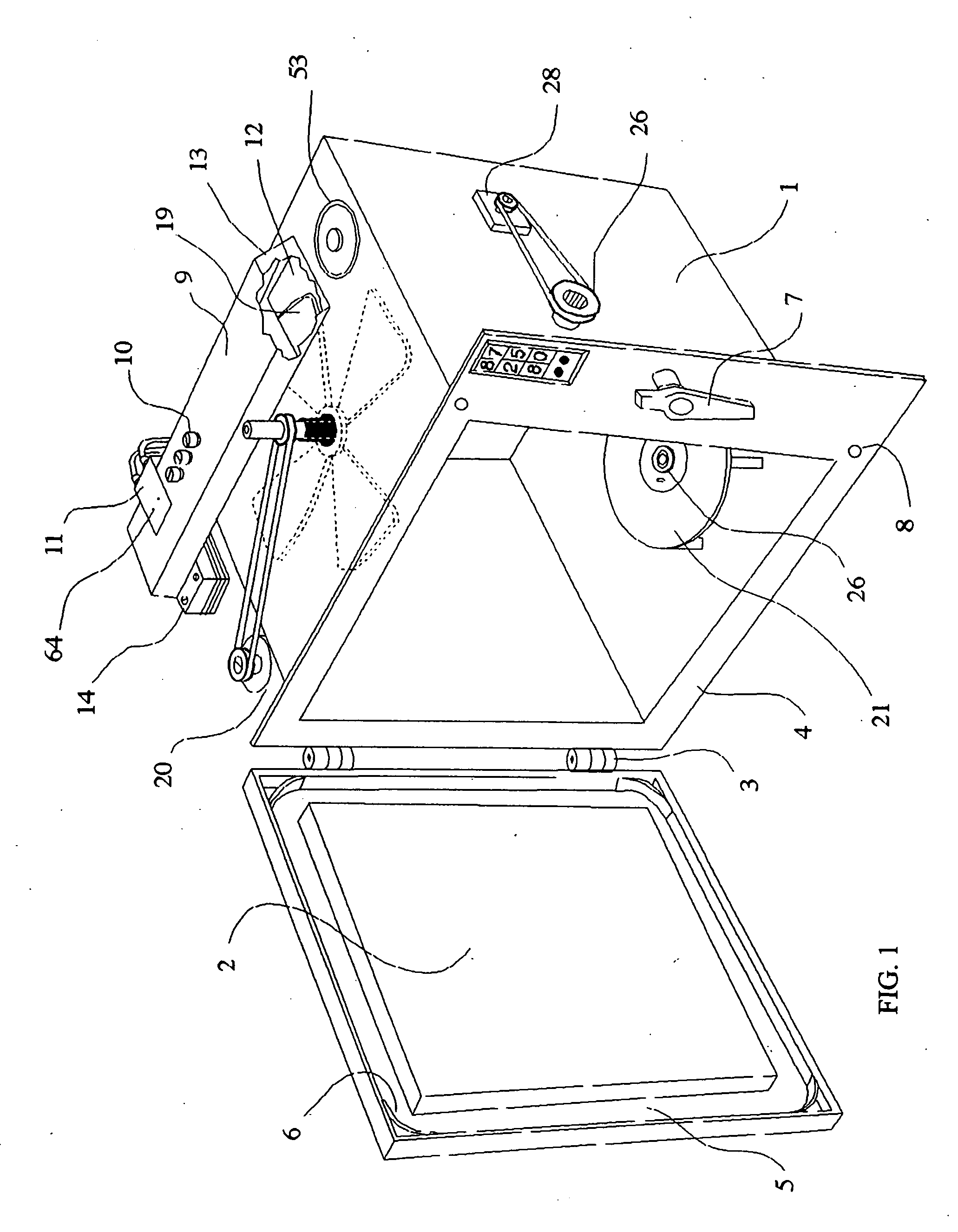

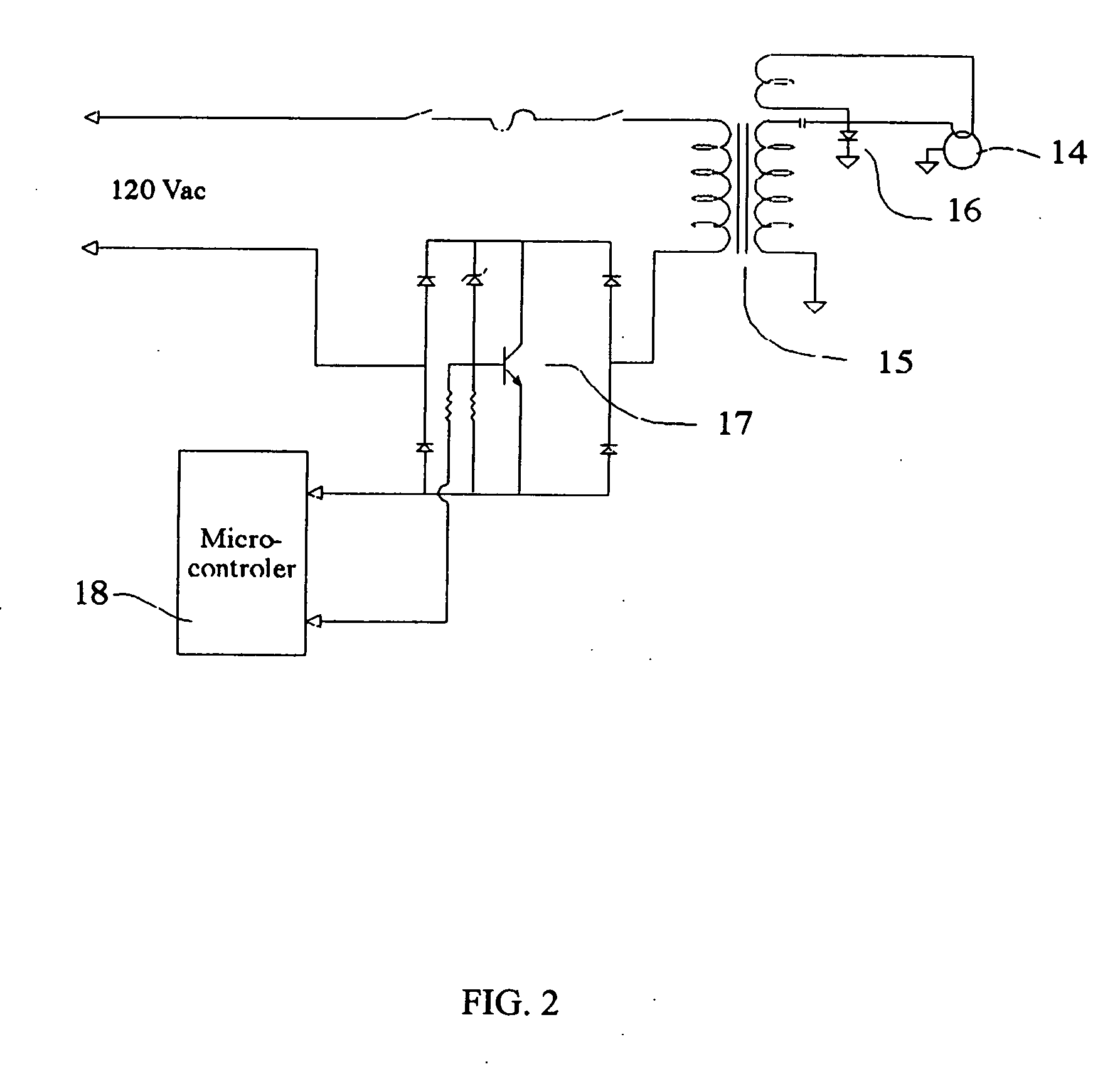

The present invention is a microwave

polymerization system for dentistry that utilizes specifically controlled microwave energy to cure polymer materials so as to produce dental prosthetics and dental composites. Unlike the microwave energy delivered by commercial microwave ovens which is controlled by pulsing a maximum output power on and off at a given

duty cycle, the present invention utilizes metered and controlled microwave energy that is preferably continuous and

voltage controlled, and regulates the application of this microwave energy by use of various feedback mechanisms. The metered and controlled microwave energy enables a higher degree of conversion and cross-linking of monomers into polymer chains in the polymerization process, thereby enhancing the physical and

biocompatibility characteristics of both dental prosthetics and dental composites made in accordance with the present invention. In an extra-oral embodiment, gaseous pressure is applied to the

resin matrix during the polymerization process to further enhance the polymerization process. In an intra-oral embodiment, the polymerization process can be accomplished with less overall energy and with composite-matrices that maximally absorb the microwave energy so as to reduce heating of adjacent tissue.

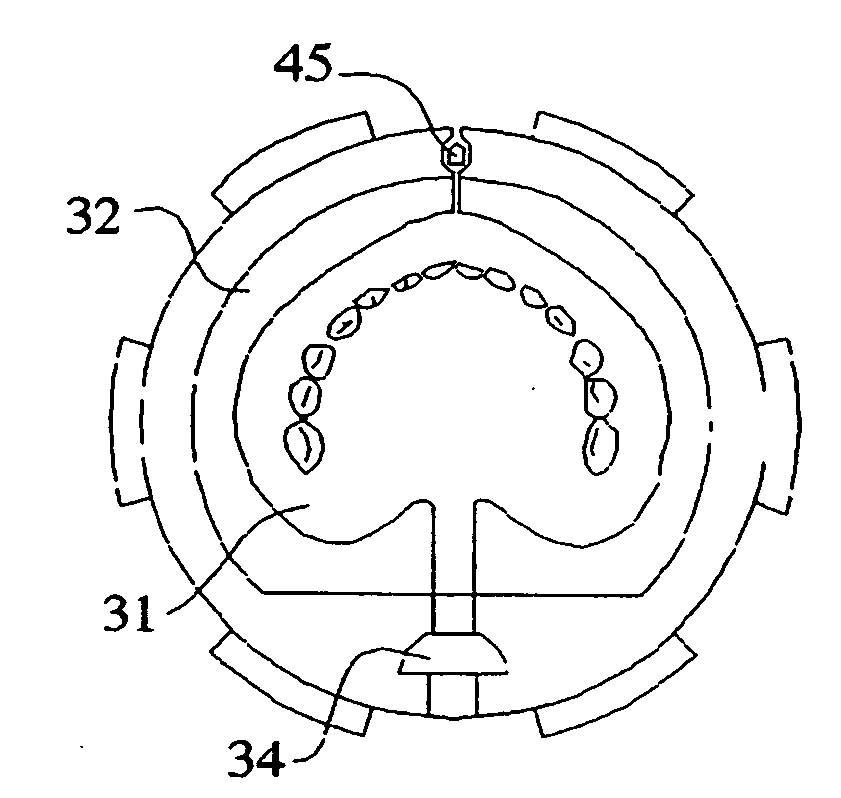

In another embodiment, a hand-held dental tool is designed to apply continuous microwave energy in accordance with the intra-oral embodiment of the present invention for use in creating dental composites directly in a patient's mouth.

Microwave energy having a frequency of between 1 GHz to 50 GHz, and preferably between 14 GHz to 24 GHz, is applied by an antenna at the distal end of the hand-held tool which is connected via a conductor or wave guide to a microwave generator that supplies low power microwave energy in response to precisely controlled voltages. Preferably, the microwave energy power is less than about 10 W and ideally, between 3 W and 5 W, and the control voltages operate between 12 V and 65 V, depending upon the desired

curing time and the particular composition of the

resin matrix to be cured. Preferably, the antenna and distal end of the hand-held tool are structured to enable the operator to exert some degree of pressure on the composite resin-matrix in the mouth while it is being cured by the application of microwave energy. The low power microwave energy provided by the hand-held tool of this embodiment is safe for intermittent

human exposure as the power and frequency ranges emitted by the antenna are similar to that emitted by cellular telephones.

Login to View More

Login to View More  Login to View More

Login to View More