Exhaust gas cleaner for internal combustion engine with particulate filter having heat-absorbing area

a technology of exhaust gas cleaner and particulate filter, which is applied in the direction of machines/engines, separation processes, transportation and packaging, etc., can solve the problems of rapid chain reaction, inability to absorb pm combustion heat, and rapid burn of pm, and achieve the effect of increasing the heat capacity of the cellular walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

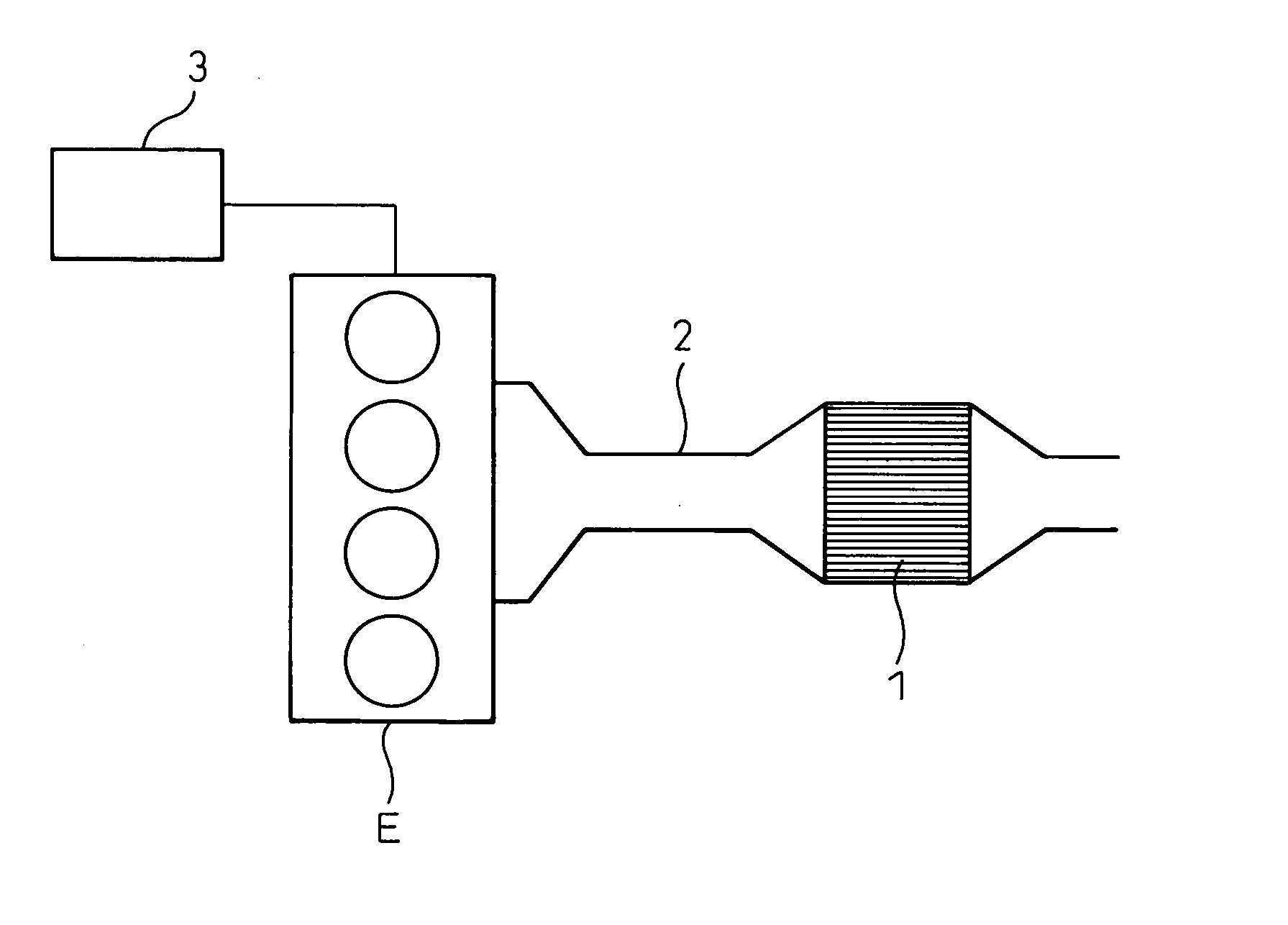

[0053] the present invention will be described in detail below with reference to the attached drawings. FIG. 1A is a schematic view showing a whole construction of an exhaust gas cleaner for an internal combustion engine to which the present invention is applied. As illustrated, an exhaust pipe 2 of an internal combustion engine E has a large diameter portion on its way for accommodating a particulate filter 1 therein. The internal combustion engine E is, for example, a diesel engine, and the particulate filter 1 is a diesel particulate filter (DPF) for collecting particulates (PM) exhausted from the diesel engine. The particulate filter 1 is regenerated by burning to remove the collected PM at suitable times by using a particulate filter regenerating means 3.

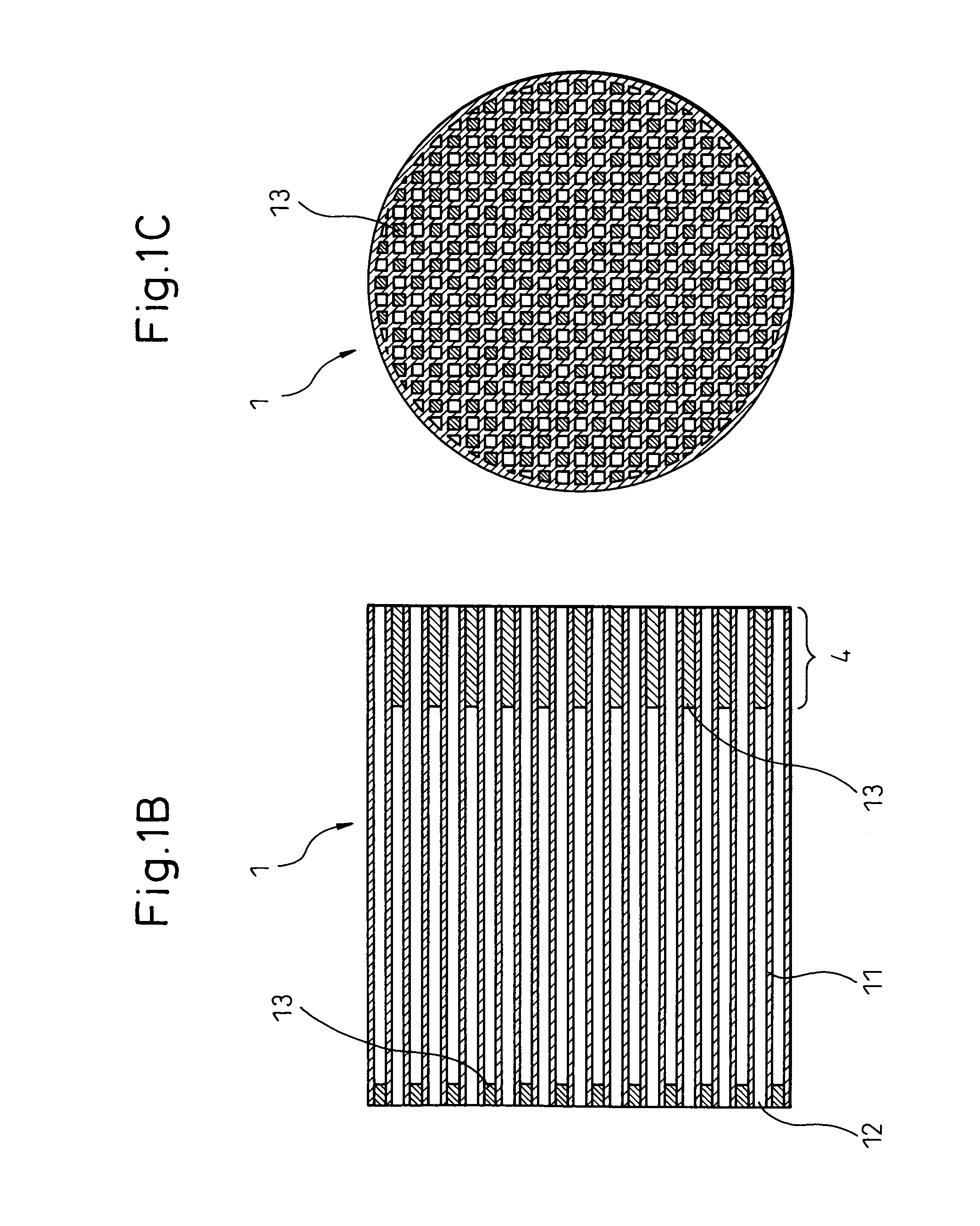

[0054] As shown in FIGS. 1B and 1C, the particulate filter 1 has a columnar monolithic structure internally partitioned by porous cellular walls 11 extended in an axial direction of the filter 1 to have a number of cells 12 arr...

second embodiment

[0059] As shown in FIGS. 2A and 2B, the particulate filter 1 may have a heat-absorbing area 4 formed by a structure in that all the clogged sections 13 provided at the exhaust gas flowing-out side end are deeply clogged (see FIG. 2A) or a structure in that part of the clogged sections 13 provided at the exhaust gas flowing-out side end are solely deeply clogged at a predetermined depth in a second embodiment as shown in FIG. 2B. While the deeply clogged sections 13A and the normally clogged sections 13B are substantially uniformly arranged in the latter case, a ratio or the arrangement thereof may be changed and suitably determined so that the maximum temperature does not exceed the allowable limit based on the temperature distribution in the particulate filter 1 during the regeneration thereof. In such a manner, if all the clogged sections 13 in the heat absorbing area 4 are not deeply clogged but the deeply clogged sections are selectively provided, it is possible to provide an ef...

third embodiment

[0060] shown in FIG. 3, the deeply clogged section 13A constituting the heat absorbing area 4 is not arranged in an outer circumferential regions 14 of the particulate filter 1, but the deeply clogged sections 13A having a predetermined depth are solely arranged in a central region and the vicinity thereof. In the drawing, while the deeply clogged sections 13A having a predetermined depth and the sections 13B having an normal depth are substantially uniformly arranged in the central region and the vicinity thereof, the deeply clogged structure may be provided in all the central region and the vicinity thereof in the particulate filter 1 except for the outer circumferential regions 14 thereof. As the outer circumferential region 14 dissipates heat more easily than the central region because the former is brought into contact with a wall of the exhaust pipe 2, a risk of exceeding the allowable temperature is less even if it does not rely on the deeply clogged structure. Accordingly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com