Power generating device

a power generation device and power generation technology, applied in the direction of electrochemical generators, machines/engines, liquid fuel engines, etc., can solve the problems of short life of the turbo-air compressor, high noise, and high power consumption, so as to reduce the power consumption of the air compressor, prolong the life of the compressor, and suppress the deformation of the revolution scroll member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

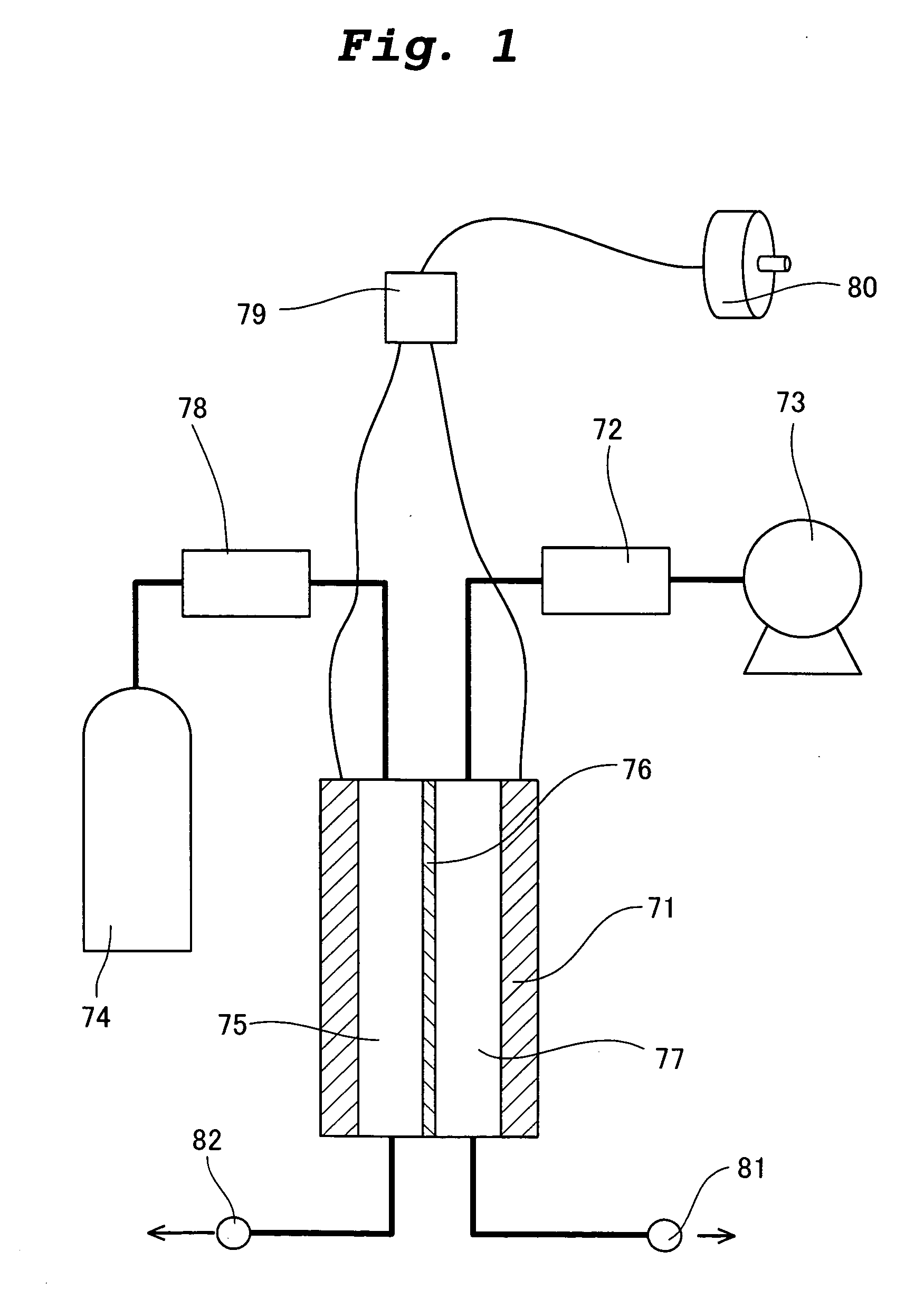

[0065] An electric power generator according to an embodiment of the present invention will be explained with reference to the drawings. FIG. 1 is a block diagram of the electric power generator of the invention.

[0066] A structure of the electric power generator using a polyelectrolyte fuel cell according to this embodiment is as follows. That is, a fuel cell 71 comprises a fuel pole 75, an electrolytic film 76 and an air pole 77. Air is pressurized by an air compressor 73 and is humidified by an air humidifier 72, and is supplied to an air pole 77. Hydrogen is adjusted in pressure at a pressure governor valve (not shown) from a hydrogen bomb 74, humidified by a hydrogen humidifier 78, and supplied to a fuel pole 75. According to the above structure, in the fuel cell 71, hydrogen supplied to the fuel pole 75 becomes hydrogen ion, the hydrogen ion passes through the electrolytic film 76 and is moved to the air pole 77. In the air pole 77, the transmitted hydrogen ion and oxygen in t...

embodiment 2

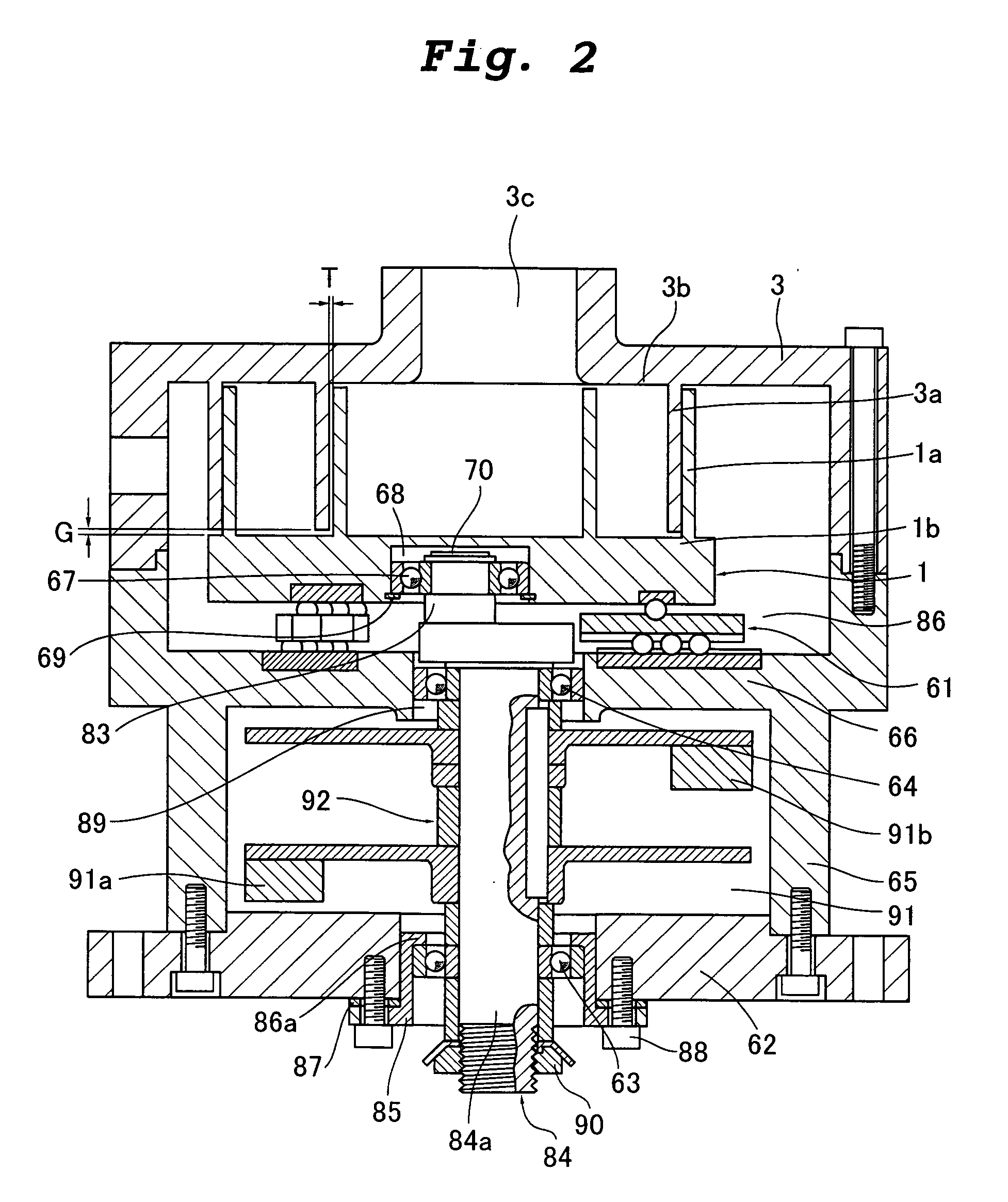

[0067] An air compressor of an embodiment used in the electric power generator of the invention will be explained next. FIG. 2 is a sectional view showing the air compressor of the embodiment of the invention. A drive motor for driving a compressing mechanism is not illustrated in the drawing.

[0068] A scroll compressor as an air compressor shown in FIG. 2 includes a revolution scroll member 1 and a fixed scroll member 3. According to the revolution scroll member 1, a revolution scroll lap 1a stands on a revolution lap support disk 1b having a revolution shaft support hole 68. A drive shaft 84 includes a main shaft 84a provided at its end with an eccentric shaft 83. The eccentric shaft 83 is eccentric from the main shaft 84a. A ball bearing 67 is fitted over the eccentric shaft 83. The revolution scroll member 1 is pivotally supported by the drive shaft 84 through the ball bearing 67.

[0069] The eccentric shaft 83 is provided with a shaft C shaped detent ring 70 so that the eccentri...

embodiment 3

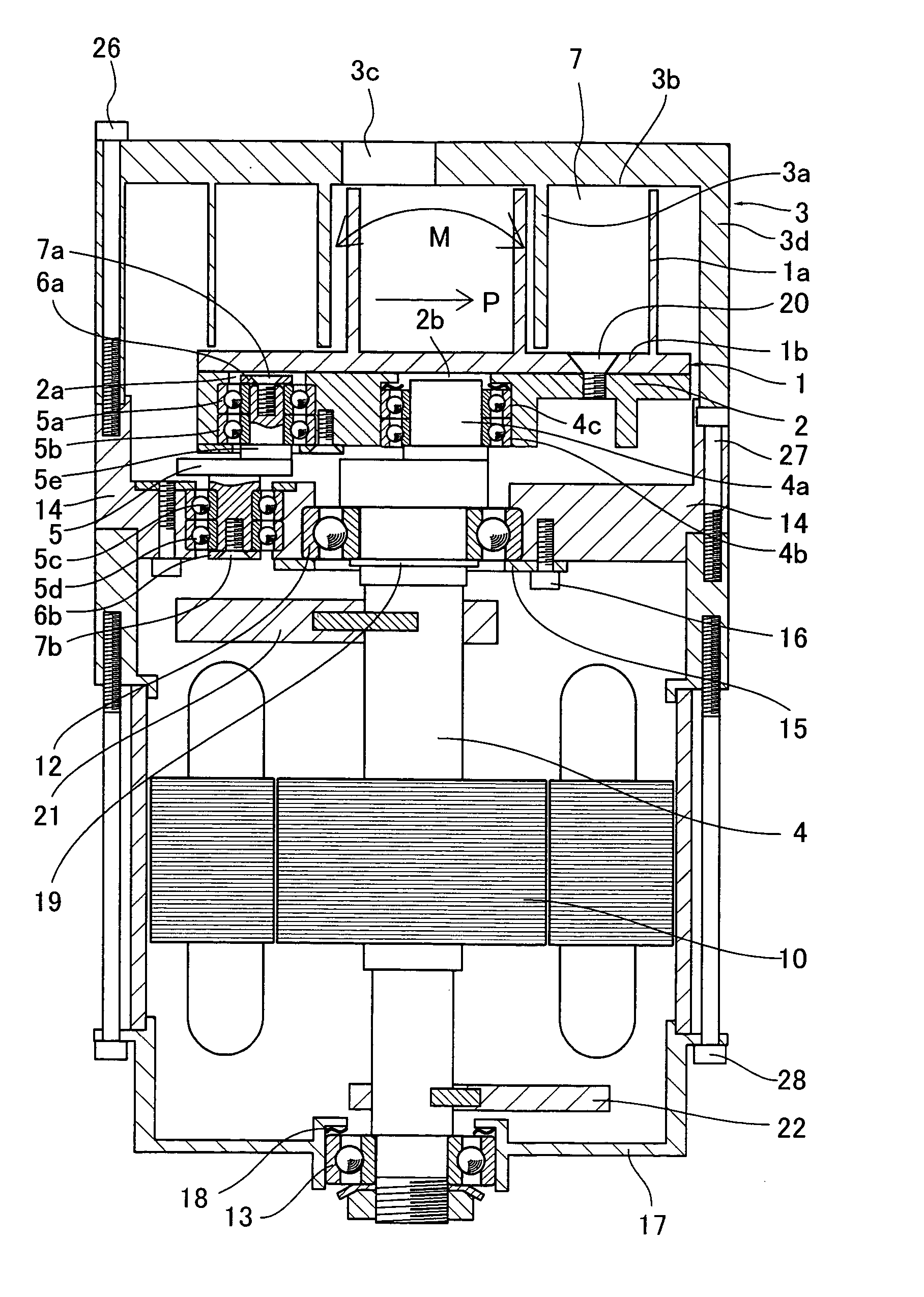

[0079] An air compressor according to another embodiment used for the electric power generator of the invention will be explained next with reference to the drawings. FIG. 3 is a sectional view showing the air compressor of the other embodiment of the invention.

[0080] A scroll compressor as the air compressor shown in FIG. 3 comprises a compressing mechanism, a scroll drive section and an assembling bolt. The compressing mechanism comprises a revolution scroll member 1 which engages with a revolution disk 2, and a fixed scroll member 3. The scroll drive section comprises a revolution support plate 14, a drive motor 10 having a drive shaft 4 which is to be inserted into the revolution support plate 14, and a balance protection cover 17 for protecting the drive motor 10 and a balancer weight 22. Detailed structure will be explained.

[0081] A revolution scroll lap 1a stands on one of surfaces of a revolution lap support disk 1b of a revolution scroll member 1. The revolution lap suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com