Piston ring excellent in resistance to scuffing, cracking and fatigue and method for producing the same, and combination of piston ring and cylinder block

a technology of scuffing, cracking and fatigue, and excellent resistance of piston rings, which is applied in the field of piston rings, can solve the problems of scuffing of piston rings and the liable roughness of the surface of the block, and achieve the dimension stability of the piston rings, prevent softening, and enhance wear and scuffing resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-11 (

J1-J11) and Comparative Examples 1 -8 (H1-H18)

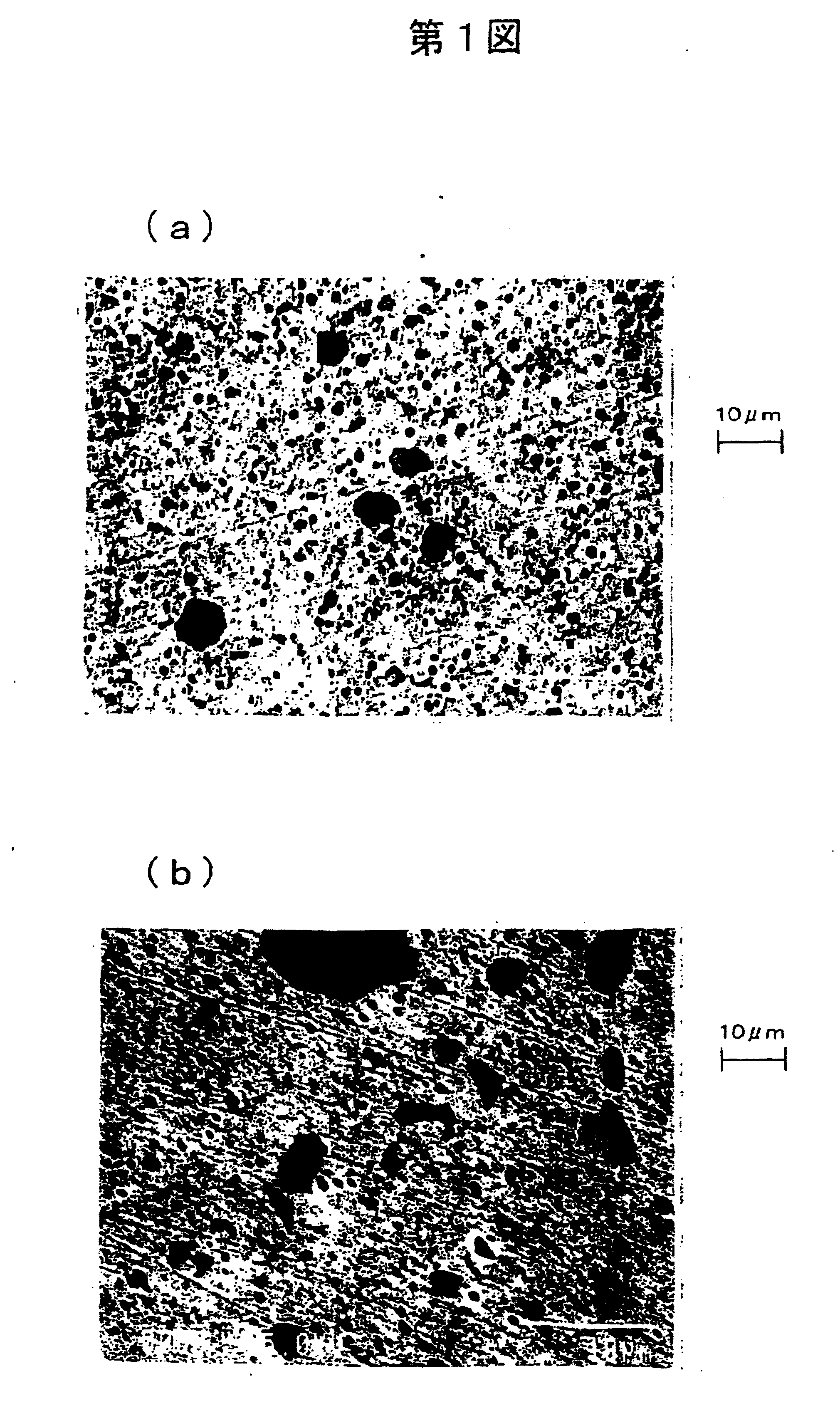

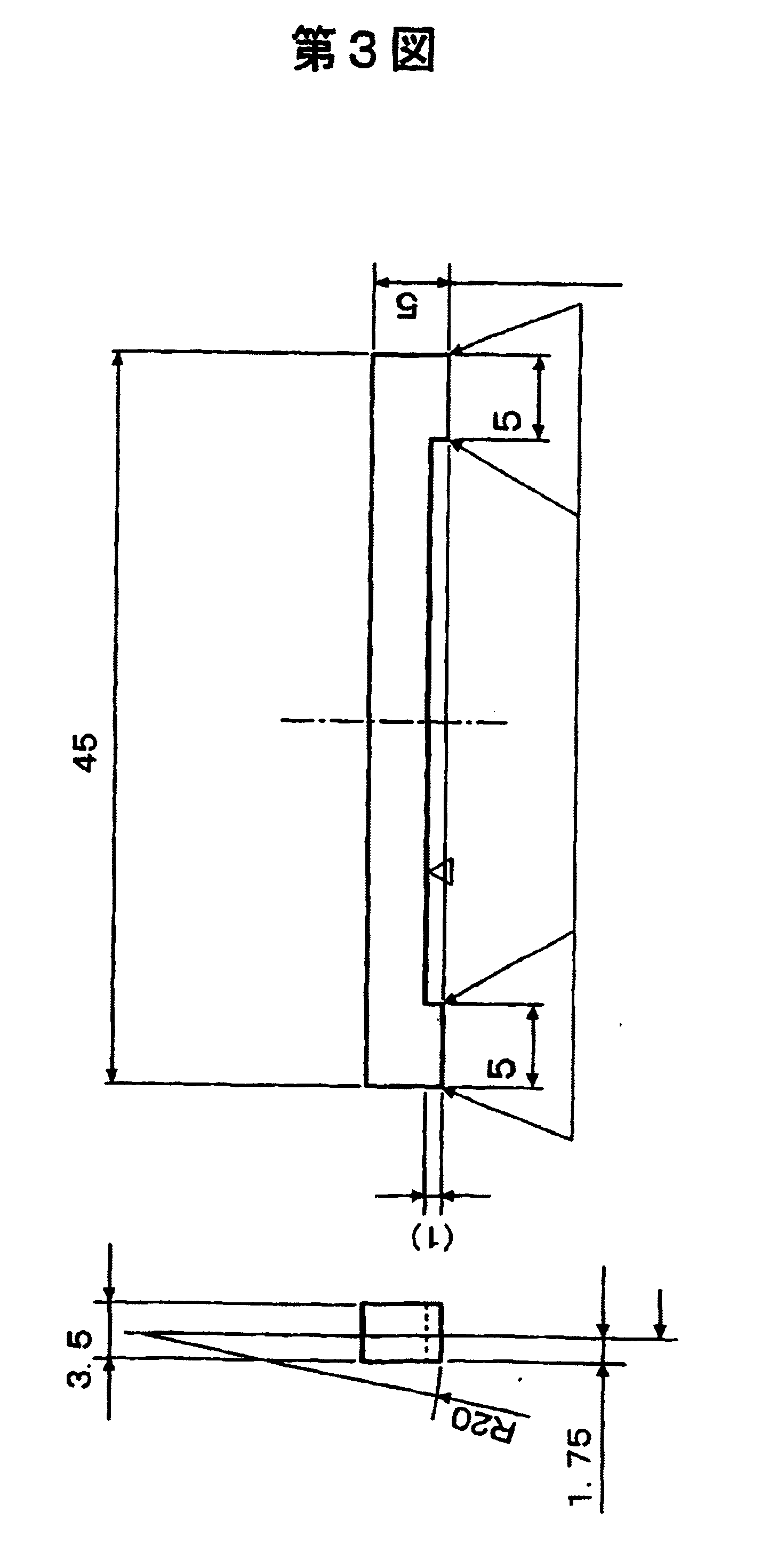

[0050] The high chromium martensitic stainless steels having a composition shown in Table 1 were melted in an amount of 10kg in a vacuum induction melting furnace. However, less than 0.2% of N was added to the steel during melting under the normal pressure, while 0.2% or more of N was added to steel during melting under pressure N.sub.2 gas atmosphere. Wire material having 12 mm of diameter was obtained by hot working. After acid cleaning, spheroidizing annealing was carried out at 750.degree. C. for 10 hours. A wire having a rectangular cross section of 3.5 mm.times.5.0 mm was produced through working steps. The wire was passed through a quenching furnace (Ar protective atmosphere) and a tempering furnace (Ar protective atmosphere). The air quenching was carried out from 930.degree. C. after keeping approximately 10 minutes at that temperature. The tempering was carried out at 620.degree. C. for approximately 25 minutes.

[0051] The wires...

examples 12-14 (

J12-J14) AND COMPARATIVE EXAMPLES 9-11 (H9-H11)

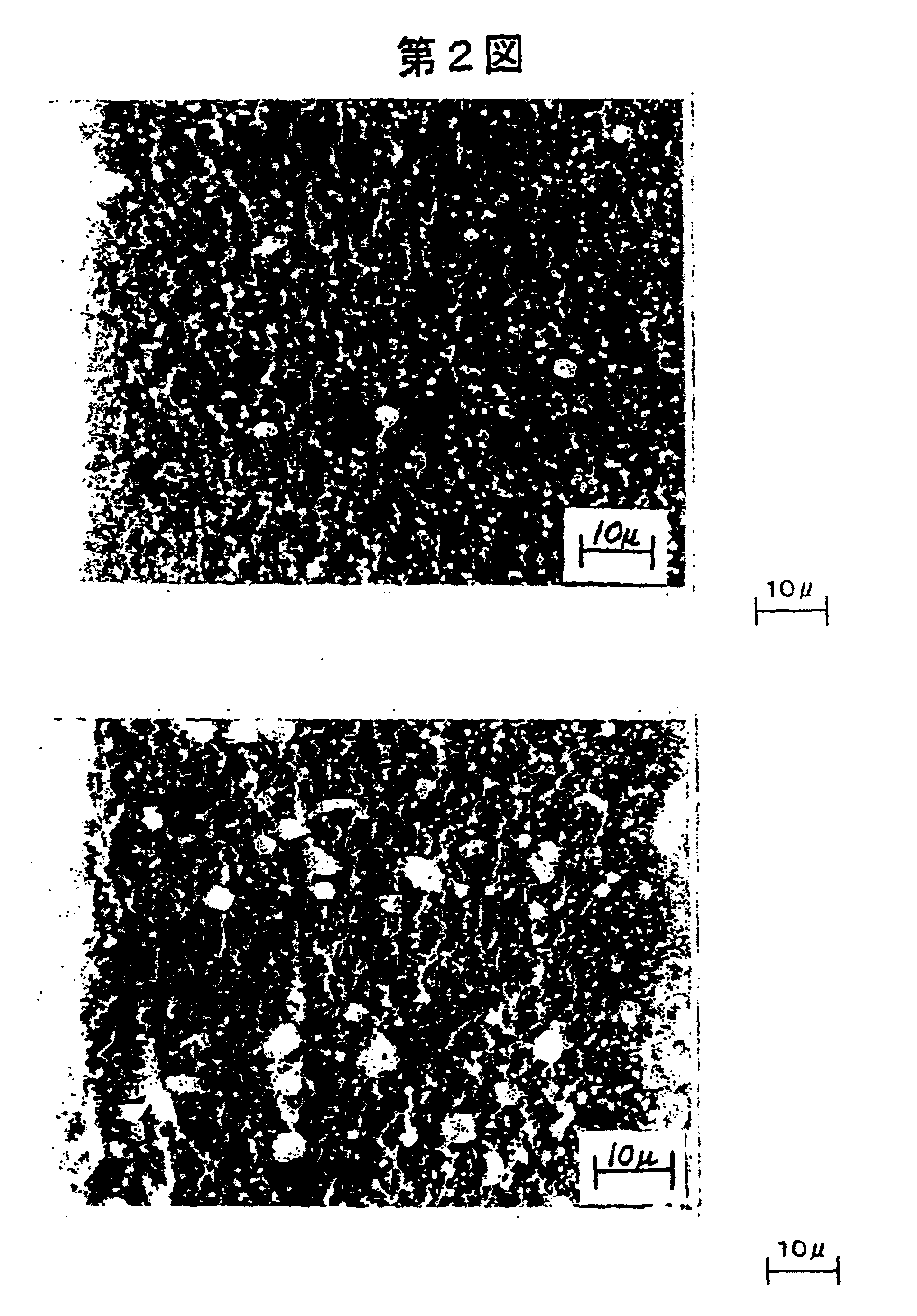

[0064] The materials having the chemical Composition of Example 1 were worked into a wire and air quenched from the temperature shown in Table 4. The gas nitriding treatment was carried out by the same method as in Example 1. The microstructure of the nitriding layer was quantitatively analyzed. The results are shown in Table 4.

4 TABLE 4 Hard Particles of Sliding Longest Length Nitriding Layer of Grain Boundary Average Largest Compound in Quenching Particle Particle Area Cross Section of Temperature Diameter Diameter % Nitriding Layer (.degree. C.) (.mu.m) (.mu.m) (%) (.mu.m) H9* 800 0.3 5 15.4 14 J12 870 0.5 5 19.4 11 J13 920 1.3 6 18.5 15 J14 980 1.8 6 17.4 18 H10 1030 2.3 9 14.7 31 H11 1080 2.8 11 11.5 49 *The hardness of the nitriding layer of Comparative Example 9 (H9) was low of Hv 860.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size(length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com