Microencapsulation of chemical additives

a chemical additive and micro-encapsulation technology, applied in the field of micro- and nano-scale capsule preparation, can solve the problems of complex additive compounds such as complex mixtures, high contact pressure, and limited chemical agents that may be encapsulated, and achieve the effect of reducing attrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

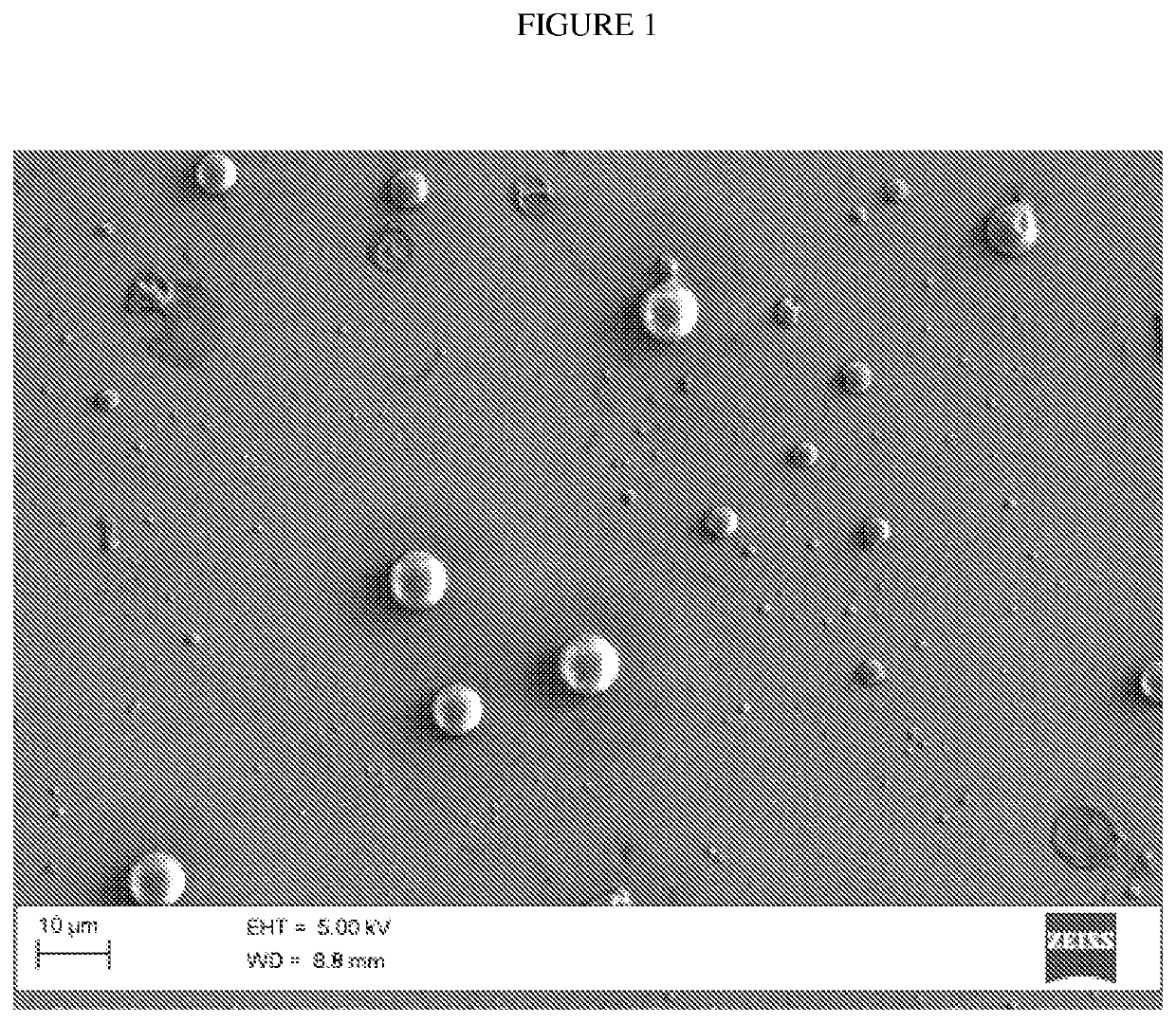

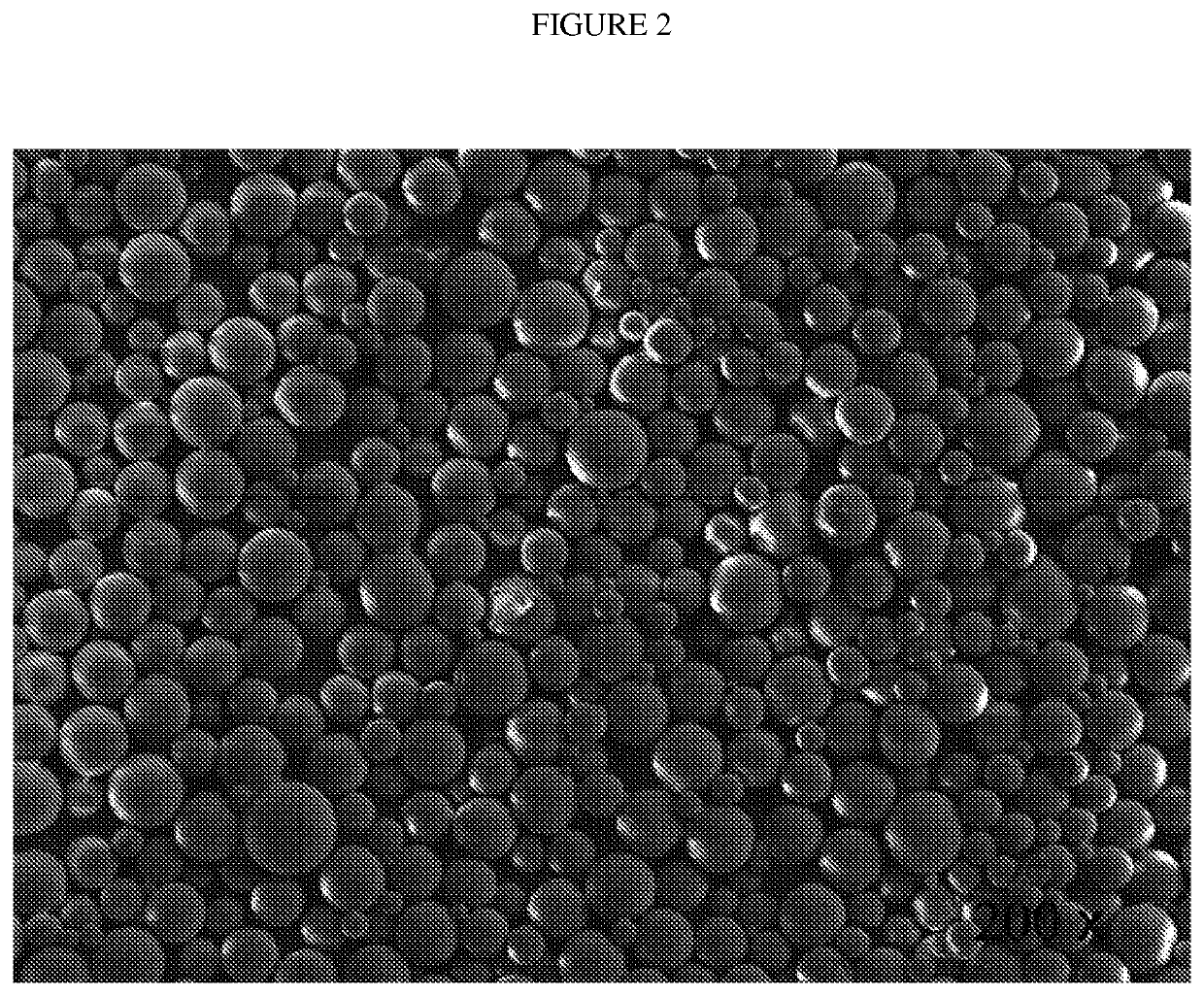

Image

Examples

example 1

Preparation of Poly(Urea-Formaldehyde) (PUF) Microcapsules

One-Step Method

[0230]At room temperature, 250 ml of deionized water and emulsifiers were mixed in a 1000 ml flask. The flask was then suspended in a temperature-controlled water bath on a programmable hotplate with external temperature probe. The solution was agitated at 500-1000 rpm, 5.00 g of urea, and 0.50 g ammonium chloride and 0.50 g of resorcinol were dissolved in the solution. The pH was then adjusted to 3.0-3.5. Then 15-25 mL of the target antioxidant was added slowly to form an emulsion and allowed to stabilize for 30 minutes. After stabilization, 12.7 g of 37 wt % aqueous solution of formaldehyde was added to obtain a 1:1.9 molar ratio of formaldehyde to urea. The emulsion was heated at a rate of 1° C. min−1 to a target temperature of 55-65° C. After 3 to 5 hours, the solution was allowed to cool to ambient temperature with stirring. The suspension of microcapsules thus formed was isolated by filtration. The microc...

example 2

Preparation of Poly(Melamine-Formaldehyde) (PMF) Microcapsules

(1) Water Phase Formation

[0233]200 ml of deionized water and emulsifier were mixed in a 1000 ml three-necked round-bottomed flask at 45 to 55° C.

(2) Oil Phase Formation

[0234]8.0 g PMF prepolymer was mixed with 30-40 g toluene to form a clear solution. Co-solvents (such as ethanol, isopropanol or THF) was also added. 20 g of core material additive was then added and the mixture was stirred at 30-40° C. for 1 hour under an atmosphere of nitrogen to form the oil phase.

(3) Oil in Water Emulsion Formation

[0235]The oil phase prepared in step 2) was added drop-wise to the stirred (500-1000 rpm) water phase prepared in step 1) at room temperature to form an oil in water emulsion, which was allowed to stabilize for 30 minutes.

(4) Polymerization

[0236]After stabilization, 6 mL H2SO4 (3 molar) was then added to the emulsion. The emulsion was then covered, blanketed under a nitrogen atmosphere and heated to 60-70° C. After 3-5 hours, ...

example 3

Internal Phase-Separation Encapsulation

(1) Water Phase Preparation

[0237]Deionized water and emulsifiers were mixed in a 1000 mL three-necked round-bottomed flask at 35 to 40° C.

(2) Oil Phase Formation

[0238]PMMA or polystyrene was mixed with a solvent to form a clear solution. The core material additive (encapsulate) was then added and the resulting mixture was stirred for 30 minutes at 30 to 40° C. to form the oil phase.

(3) Oil / Water Emulsion Formation and Polymerization

[0239]The water phase prepared in step 1) was agitated with a digital mixer at 500-1000 rpm at room temperature. The oil phase containing both the core material additive (encapsulate) and the polymer prepared in step 2) was then added to the water phase to form an emulsion and allowed to stabilize for 30 minutes. The mixture was then heated at a rate of 1° C. min−1 to a target temperature of 60° C. After 4-6 hours, the reaction was complete. The resulting suspension of microcapsules was then separated under vacuum wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com