2D circulating gravity heat pipe

A gravity heat pipe and heat pipe technology, applied in the field of heat pipes, can solve problems such as the failure of the second-dimensional circulation loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

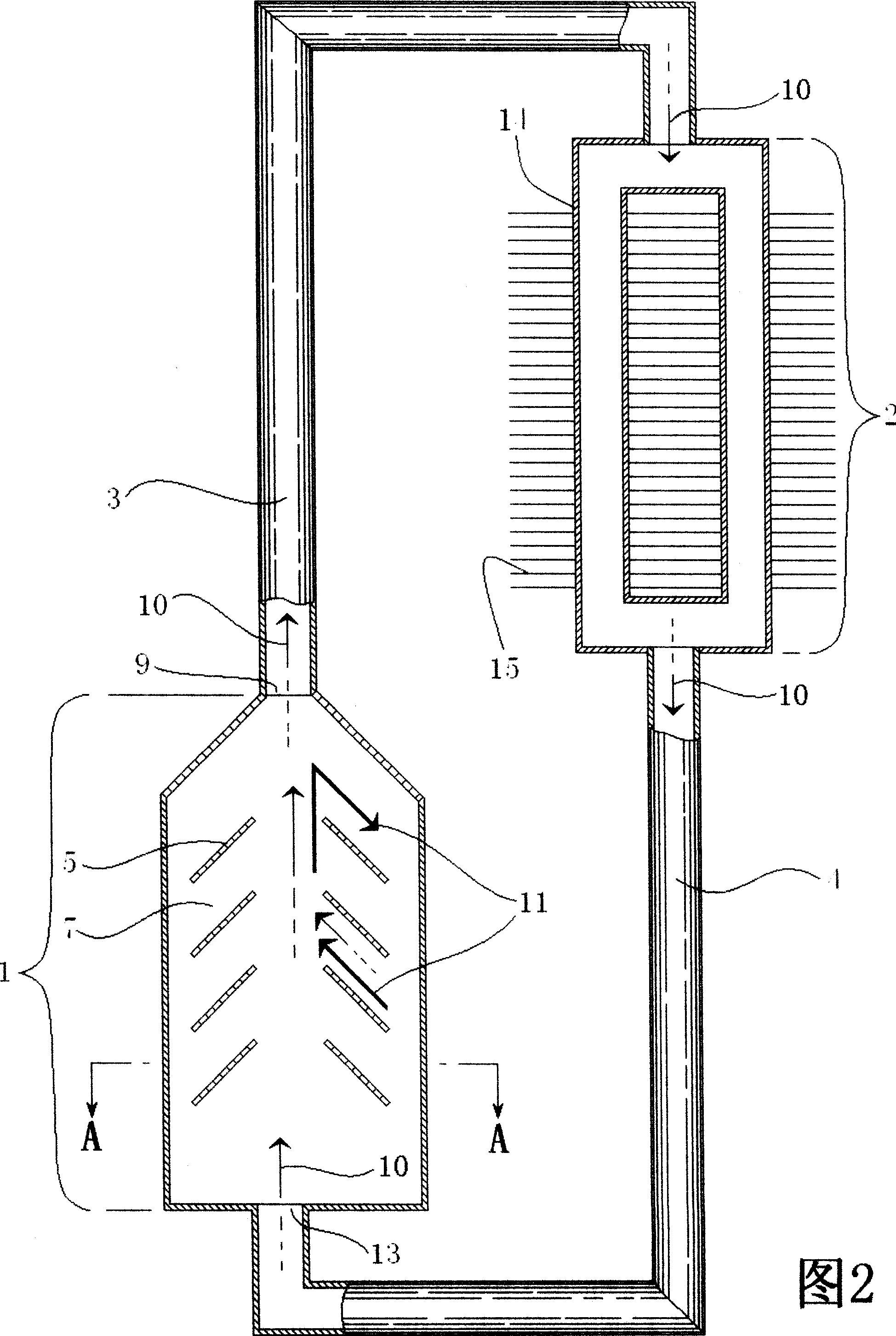

[0024] Referring to FIG. 2 , the heat pipe shown in the figure is a schematic structural diagram of the first embodiment of the present invention. In this embodiment, the heat pipe is composed of four parts: an evaporator 1 , a condenser 2 , an exhaust pipe 3 , and a liquid inlet pipe 4 . Referring to Fig. 2 and Fig. 3, the main feature of this heat pipe is that the heated wall 7 is one (or two opposite) side planes of the evaporator 1, and there are inclined guide fins 5 connected to the heated wall 7 in the evaporator 1 . As shown in FIG. 4 , the foaming arrangement 16 of the heated wall 7 is composed of tube cores 17 and grooves 18 . Next, we analyze the working process of the heat pipe. Referring to the first-dimensional circulation loop 10 shown by the dotted arrow in Fig. 2, when the heat pipe is working, the liquid in the evaporator 1 absorbs heat from the heated wall 7 and gasifies to generate bubbles, which float upward along the guide plate 5, and the bubbles float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com