Cutting liquor composition for metal processing

A metal processing and cutting fluid technology, applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the influence of rich phosphating of water body, does not involve the inhibition of microorganisms and other problems, achieves excellent corrosion resistance, excellent antimicrobial performance, Effect of inhibiting cobalt leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

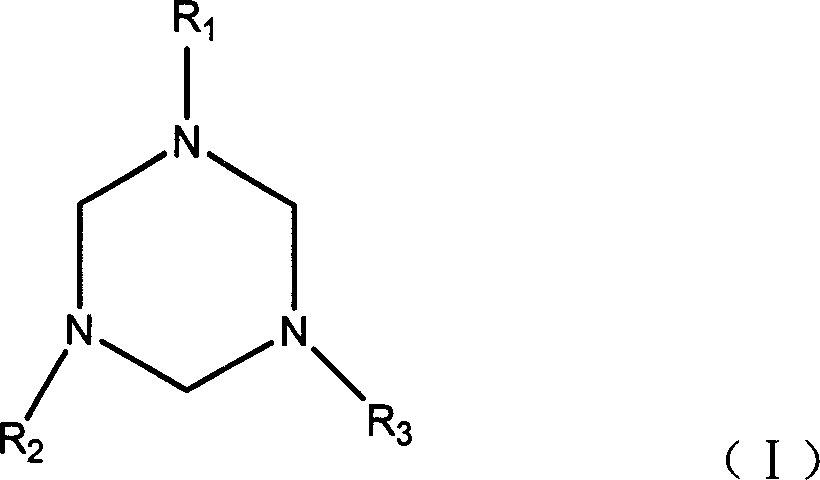

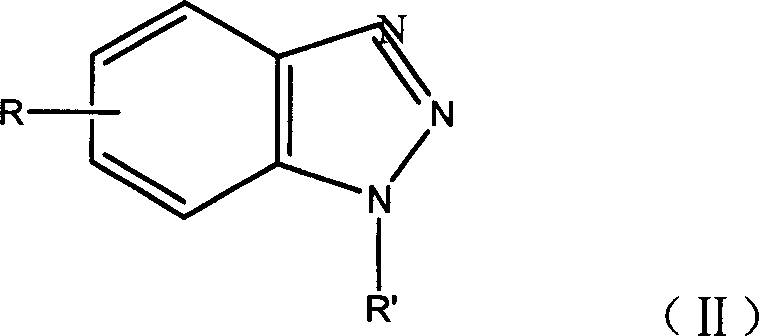

[0025] According to the percentage by weight in Table 1, weigh 3 grams of hexahydro-1,3,5-trihydroxyethyl-s-triazine, 10 grams of BA60DX, 6 grams of succinic acid, 10 grams of diethanolamine, and 5 grams of sulfurized fatty acid Soap, 0.4 g of benzotriazole, 20 g of triethanolamine and 45.09 g of water are heated and dissolved at a temperature of 50 to 70 ° C, stirred evenly, then 0.5 g of 6501 and 0.01 g of emulsified silicone oil are added, and the stirring is continued until uniform to obtain Pale yellow transparent liquid. The liquid was diluted with water at a ratio of 5% by weight to obtain a diluted liquid.

[0026] The powder alloy material used in the cobalt suppression performance test was obtained from a processing workshop and then finely ground. During the test, first measure 100 ml of diluent, then add 5 grams of cobalt-containing powder alloy material, shake fully for 2 minutes, place it at room temperature, and then shake once every 8 hours. Gram company's an...

Embodiment 2~9】 and 【 comparative example 1~3

[0028] According to each step and condition of [Example 1], the cutting fluid composition is prepared and the cobalt-inhibiting performance and the antibacterial performance of the testing cutting fluid composition are changed, but the components and contents in each cutting fluid composition are changed, and the cutting fluid composition See Table 1 for the weight percentage composition, and see Table 2 for the test results.

[0029] Table 1

[0030] components

weight%

cobalt inhibitor

Rust inhibitor

lubricant additive

corrosion inhibitor

pH adjuster

Emulsifier

water

Other additives

Example 1

3% Hexahydro-1,3,5-

Trihydroxyethyl-Mestri

10% BA60 DX

10% diethanolamine

5% sulfurized fatty acid soap

0.4% Benzotriazole

20% Triethanolamine

0.5%6501

--

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com