Fast sprue-replacing casting method and device for continuous irregular blank casting ladle

A technology of continuous casting and pouring method of shaped billets, which is applied in casting equipment, casting molten material containers, metal processing equipment, etc., and can solve the problems of deterioration of the surface and internal quality of shaped billets, uneven performance and service life, and inability to realize online replacement Nozzle and other problems can be improved to improve the surface and internal quality of the slab, improve the control accuracy, and improve the fluctuation of the molten steel level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

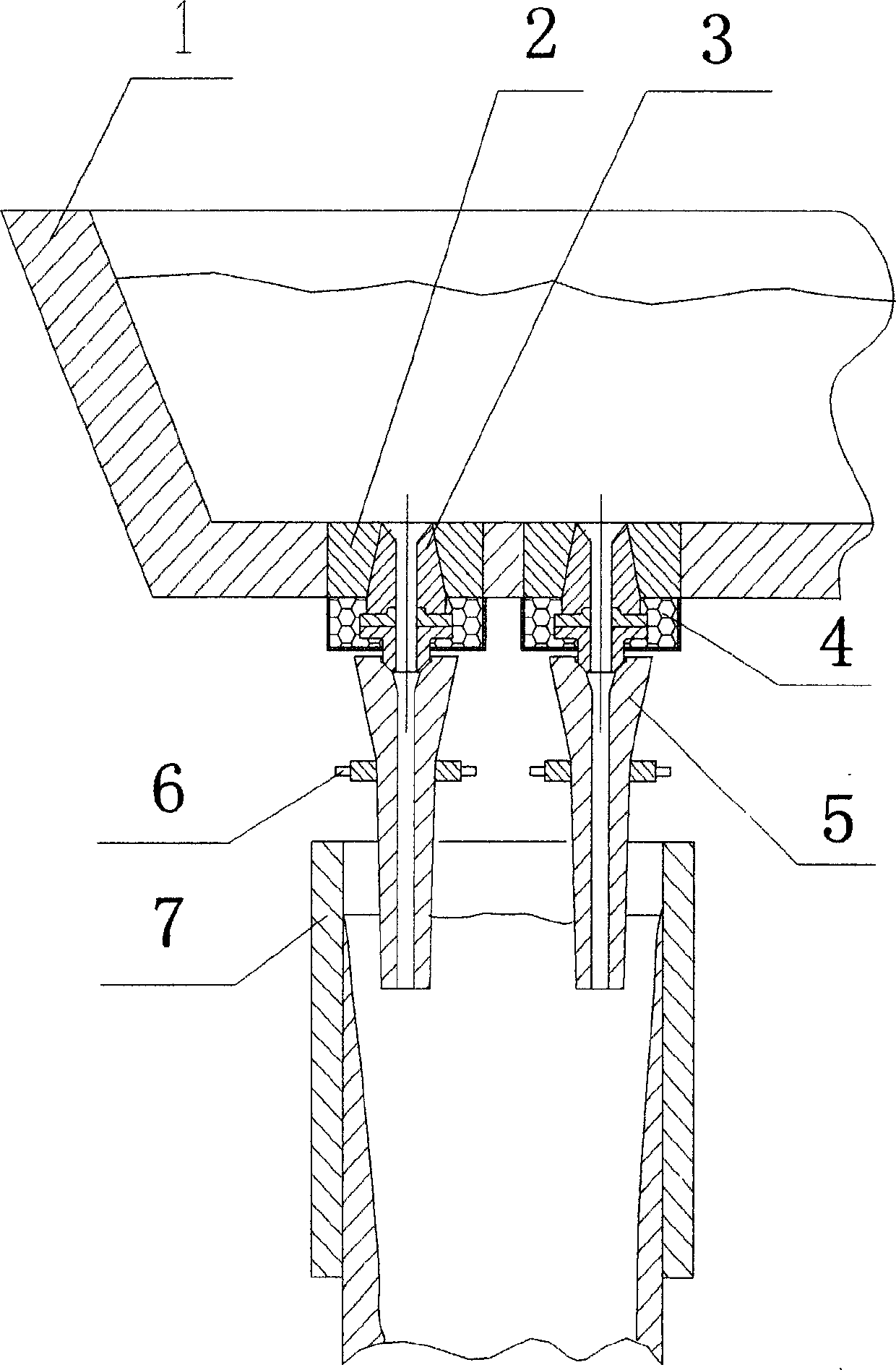

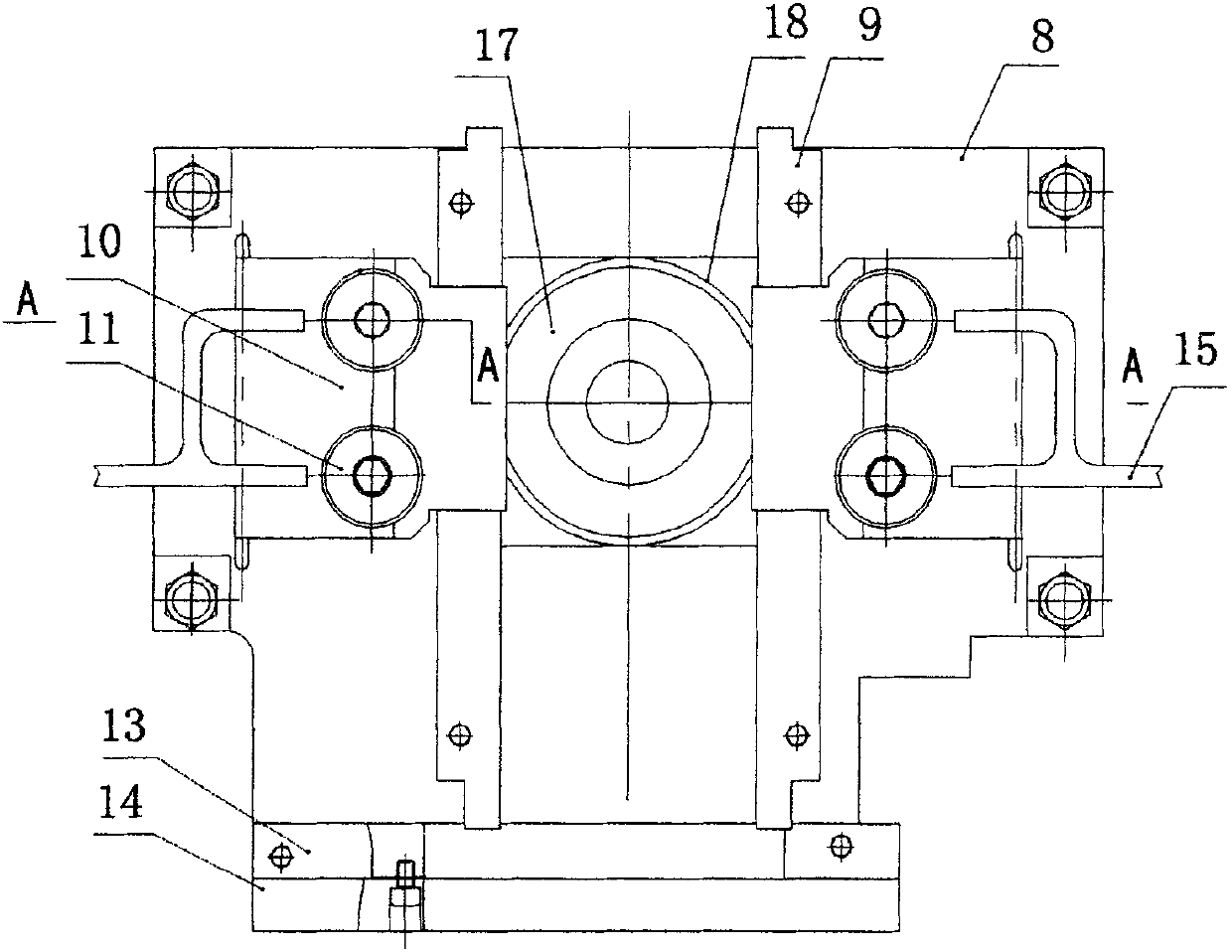

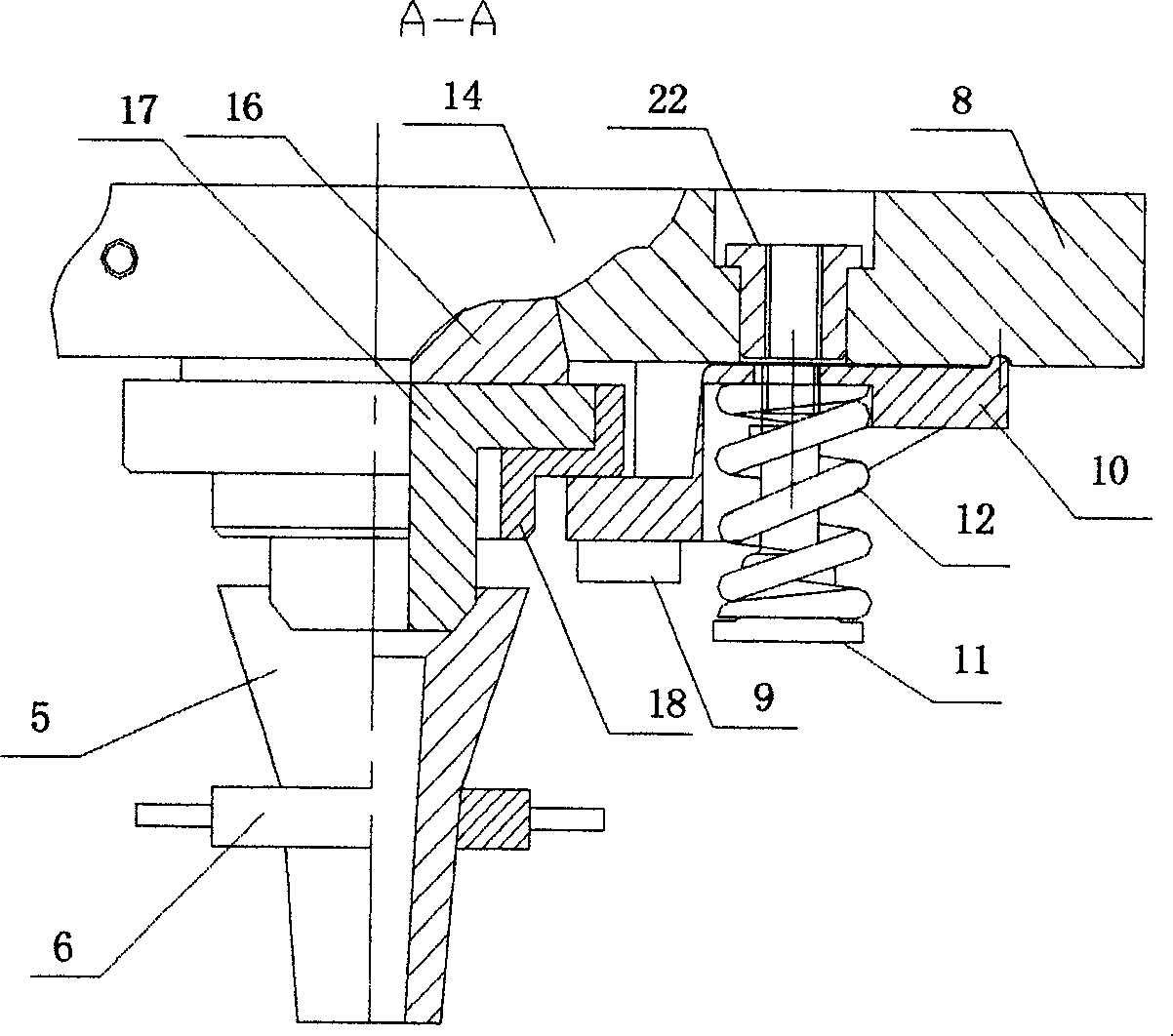

[0021] by figure 1 It can be seen that, the quick-change nozzle pouring method and device for the special-shaped billet continuous casting tundish, two independent molten steel channels are set between the tundish 1 and the mold 7, and the molten steel in the tundish 1 is injected into the mold 7 through these two independent channels. Pouring is to adapt to the characteristics of the special-shaped billet pouring, so that the molten steel flow field and temperature distribution are uniform and reasonable. The bottom of the tundish 1 is provided with two seat bricks 2 in which the tundish nozzle 3 is installed; under each tundish nozzle 3 is provided a quick-change nozzle mechanism 4, which is provided with a sliding upper nozzle 16 and a sliding lower nozzle 17, which slide upward The nozzle 16 is in communication with the tundish nozzle 3, the sliding nozzle 17 is connected with the full immersion nozzle 5, the full immersion nozzle 5 is inserted in the crystallizer 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com