Polyester industrial yarn functional additive multi-channel oil nozzle oiling device

A functional additive and polyester industrial yarn technology, which is applied in textile processing machine accessories, equipment configuration for processing textile materials, textiles and papermaking, etc., can solve the problems of endangering the health of employees, poor oiling uniformity, and large waste of oiling agent To reduce the harm to the health of employees, improve the uniformity of oiling, and reduce the waste of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

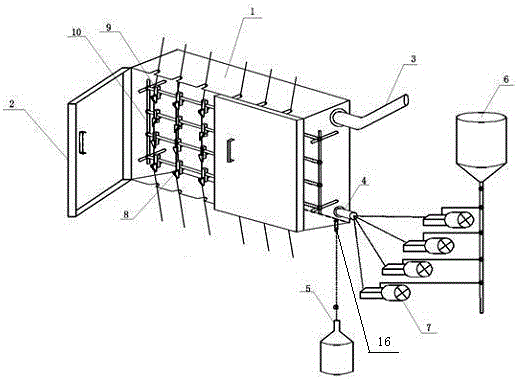

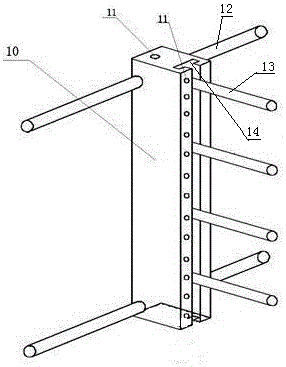

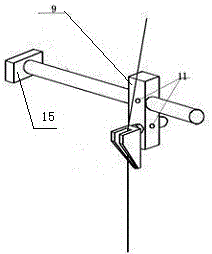

[0024] Such as Figure 1~Figure 6 As shown, the polyester industrial yarn functional additive multi-channel oil nozzle oiling device includes an oil storage tank 6, a metering oil pump 7, an oil nozzle 8 and an oil nozzle position adjustment part, and the oil nozzle 8 is connected to the upper oil tank through the oil nozzle position adjustment part In the body 1, there are at least two rows of grease nozzles 8, such as the production of 1000D-2000D, generally two rows are arranged, and the direction of the nozzles is one left and one right, and the production of more than 3000D generally requires four rows, the direction of the first row and the fourth row of nozzles Forward, the direction of the second row and the third row of oil nozzles is one left and one right, connected to the metering oil pump 7 through the oil pipe, the metering oil pump 7 is connected to the oil storage tank 6, and the metering oil pumps 7 connected to the oil nozzles 8 are connected in parallel On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com