Miniature needle array for medicine transmission and its making process

A technology for microneedle arrays and manufacturing methods, which is applied in the direction of microneedles, techniques for producing decorative surface effects, separation methods, etc., which can solve the problems of needles without sharp ends, complexity, and high requirements for the production process of microneedle arrays, and achieve production costs. Low, good drug delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

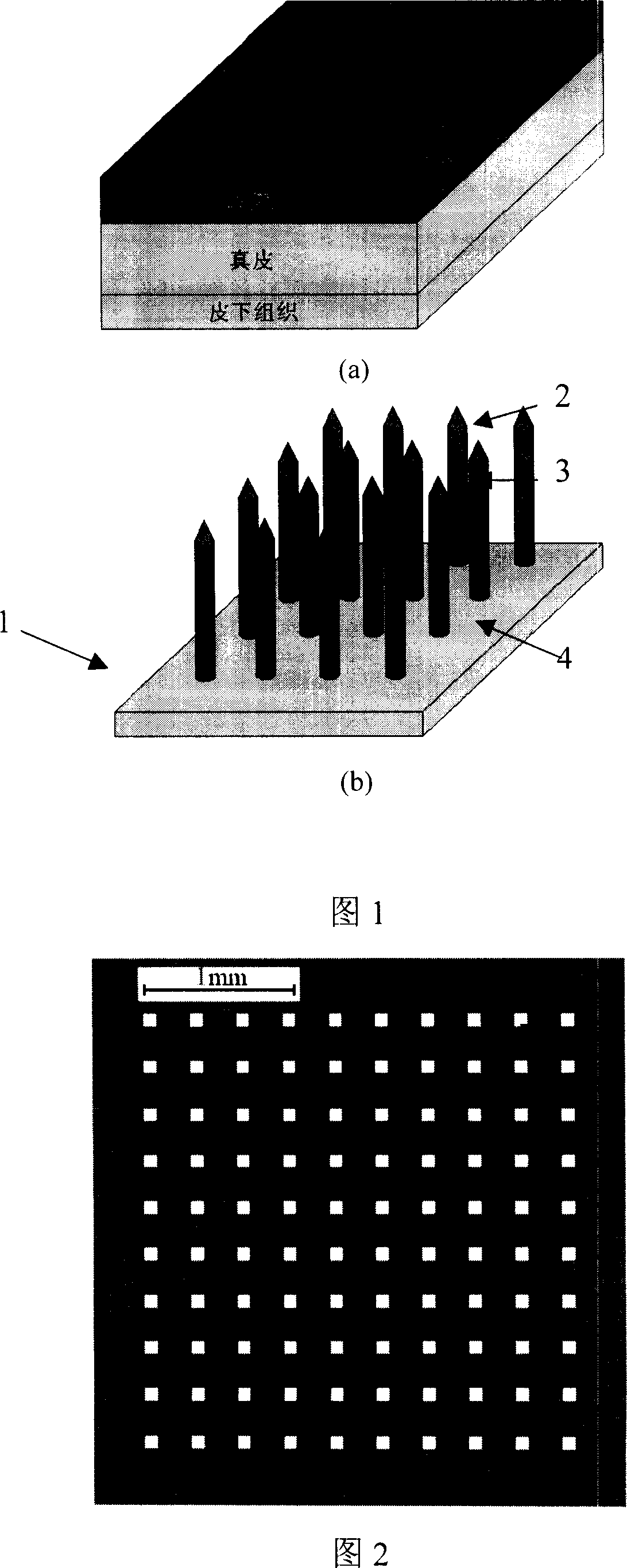

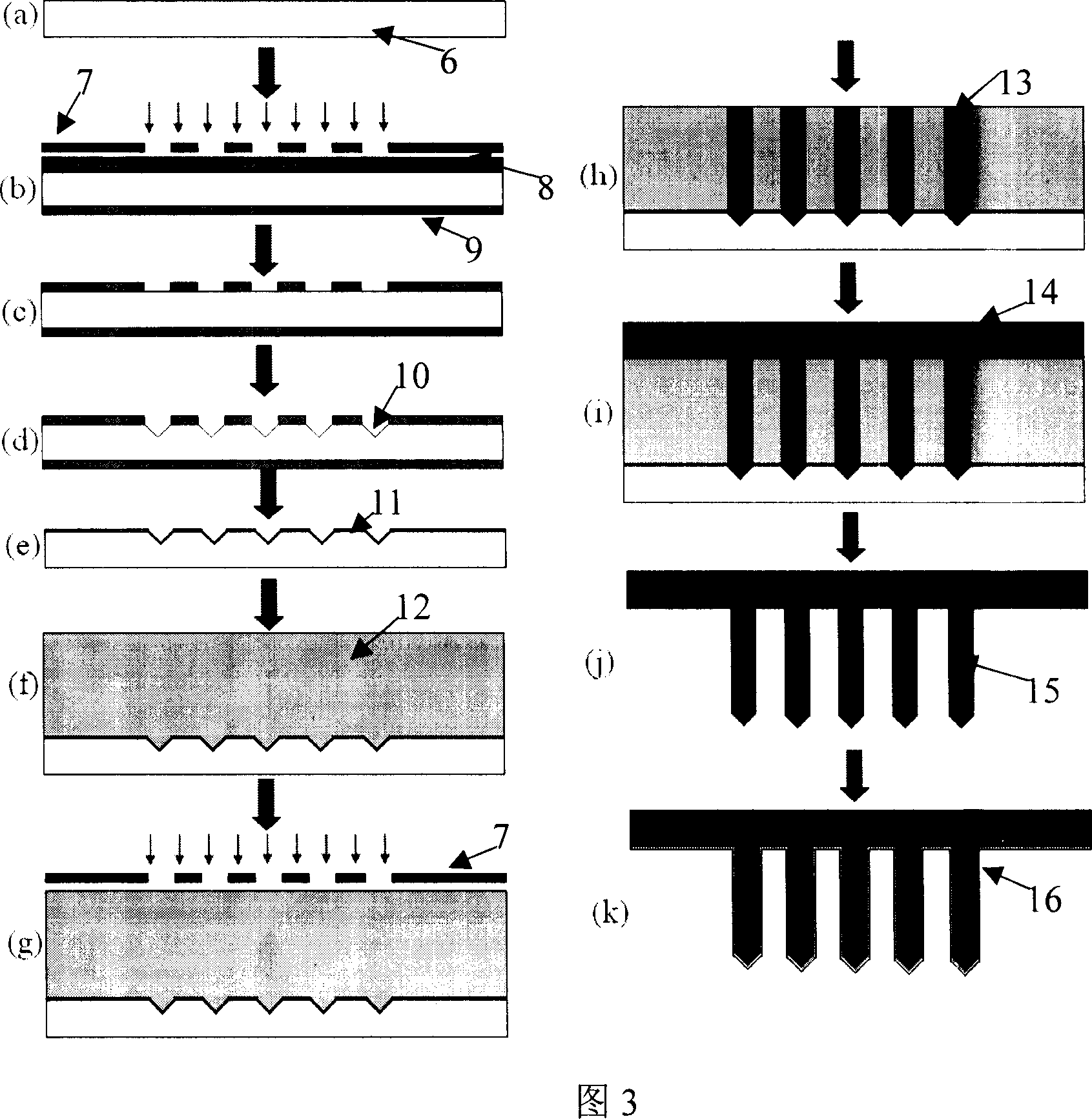

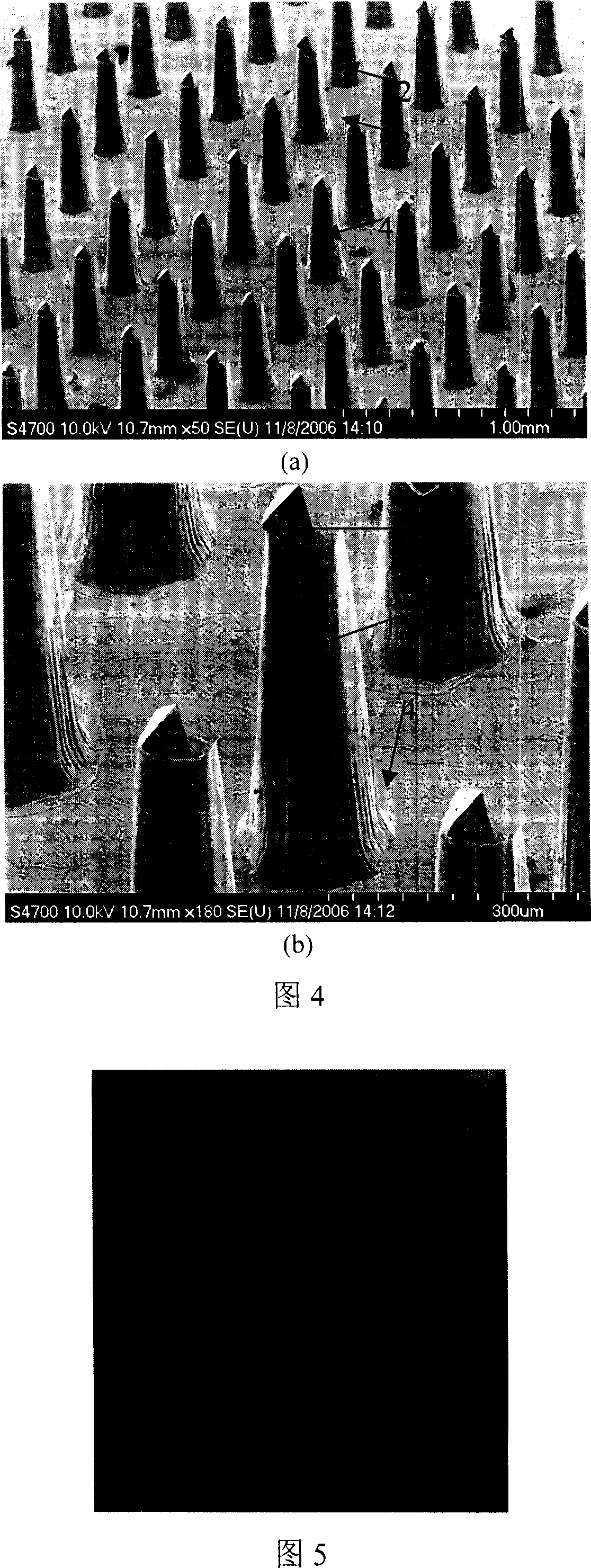

[0054] The making of embodiment 10×10 microneedle array

[0055] The following parameters are considered when designing the microneedle array: the size of the main structure, the three-dimensional structure size of the microneedle structure, the thickness of the surface modification material, and so on. The designed pattern is made into a mask (as shown in Figure 2), which can be used as a mask for oxide layer etching and SU-8 photolithography at the same time, so as to be transferred to silicon wafers containing oxide layers and SU-8 photolithography. -8 on substrate. When making the layout, you can change the base area of the microneedle array, the number of microneedles, the three-dimensional structure of the needle, the distance between the needle tips and the height of the needle tip according to the actual application needs: change the unit area of the microneedle array on the mask according to the toughness and thickness of the skin that need to be penetrated , so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com