Cosmetic compositions containing at least one conditioning agent and at least one ethylene polymer with polyethylene glycol grafts

A kind of cosmetic composition, technology of composition, applied in the field of composition of olefin copolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

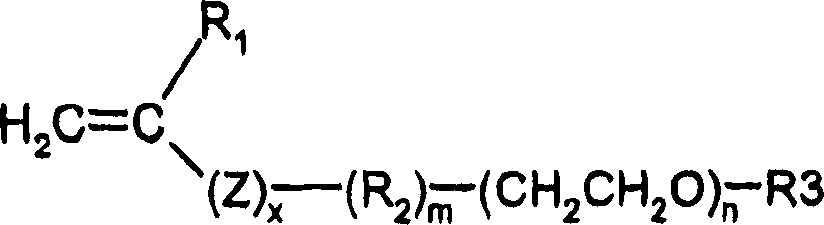

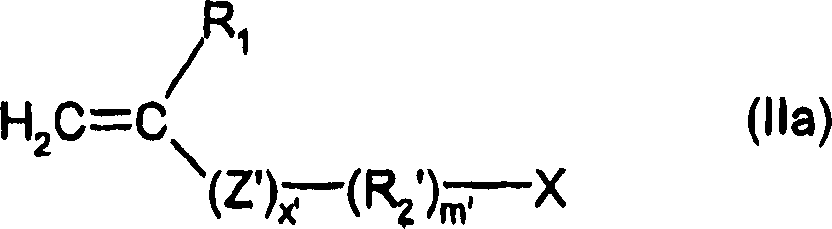

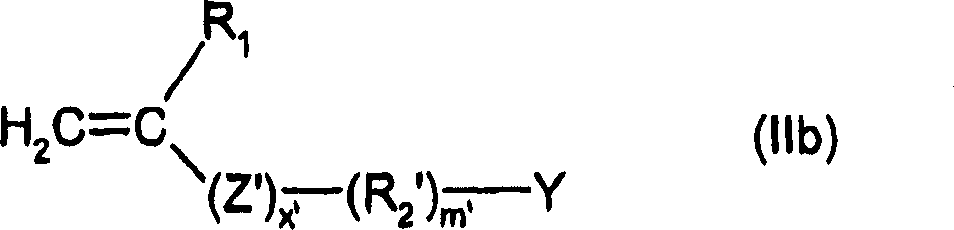

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0619] 75 ml of methyl ethyl ketone (MEK) was put into a reactor (four-necked flask) equipped with two addition funnels, a condenser and a mechanical stirrer, and heated to 80°C.

[0620] Meanwhile, a solution comprising monomer: 50 g of polyethylene glycol methacrylate (MPEG 550), 50 g of dimethylaminopropyl methacrylamide (DMAPMA) and initiator: 0.5 g of (Trigonox 21S) was prepared 1. Solution 2 was also prepared, comprising 75 ml of methyl ethyl ketone and 0.5 g of initiator (Trigonox 21S).

[0621] Solution 1 was dropped into the four-necked flask reactor over 1 hour, and Solution 2 was dropped over 2 hours. The resulting mixture was then kept at 80°C for 5 hours. The obtained orange-yellow solution was cooled. 95 g of polymer are obtained.

[0622] The polymer has a Brookfield viscosity of 7.5 mPa.s as measured at 25°C in a 15% solution of the polymer in MEK using a No. 1 needle mandrel at a speed of 0.1 rpm.

[0623] The polymer can then be neutralized as follows: 2...

preparation Embodiment 2

[0627] 100 ml of water was put into a reactor (four-necked flask) equipped with two addition funnels, a condenser and a mechanical stirrer, and heated to 80°C.

[0628] Simultaneously, solution 1 was prepared comprising 50 g of monomeric MPEG 550, 1 g of initiator (potassium persulfate KPS) and 50 ml of water.

[0629] Solution 2 comprising 50 g of monomeric DMAPMA 100% neutralized with betaine hydrochloride and 50 g of water was also prepared.

[0630] Solutions 1 and 2 were dropped into a four-necked flask over 1 hour. After 1 hour at 80°C, a mixture of 1 g of KPS in 50 ml of water was added dropwise over 15 minutes.

[0631] The resulting mixture was then kept at 80°C for 3 hours. 90 g of polymer neutralized with betaine hydrochloride are obtained.

[0632] The polymer has a Brookfield viscosity of 164 mPa.s, measured at 25°C in a 15% aqueous solution of the polymer at a speed of 6 rpm using a No. 1 needle mandrel.

[0633] The polymer is soluble in water (up to at leas...

preparation Embodiment 3-17

[0637] The following polymers according to the present invention or polymers of comparative examples were prepared according to the method of Example 1 (solvent method) or the method of Example 2 (water method).

[0638] Example

method and neutralization

Example 3

10% MPEG 550

90% DMAPMA

method 1

HCl

water

Example 4

25% MPEG1100

75% DMAPMA

method 1

HCl

water

Example 5

50% MPEG 1100

50% DMAPMA

method 1

HCl

water

Example 6

50% MPEG 550

50% DMAPMA

method 1

HCl

water

Example 7

50%MPEG550

50% SPE

Method 2

not neutral

water

Example 8

50% MPEG 550

50% DMAEMA

method 1

HCl

water

Example 9

50% MPEG 550

50% methacrylic acid

Pheninoethyl ester

method 1

HCl

water

[0639] Example 10

50% MPEG 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge density | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com