Method for making shadow mask of opposed-discharging type plasma plane display

A technology of a flat panel display and a manufacturing method, which is applied in the manufacturing of non-light-emitting electrodes, etc., can solve the problems of high difficulty, negative influence on the luminous efficiency of the display, and difficulty in controlling the width of the gas channel 23 and the depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

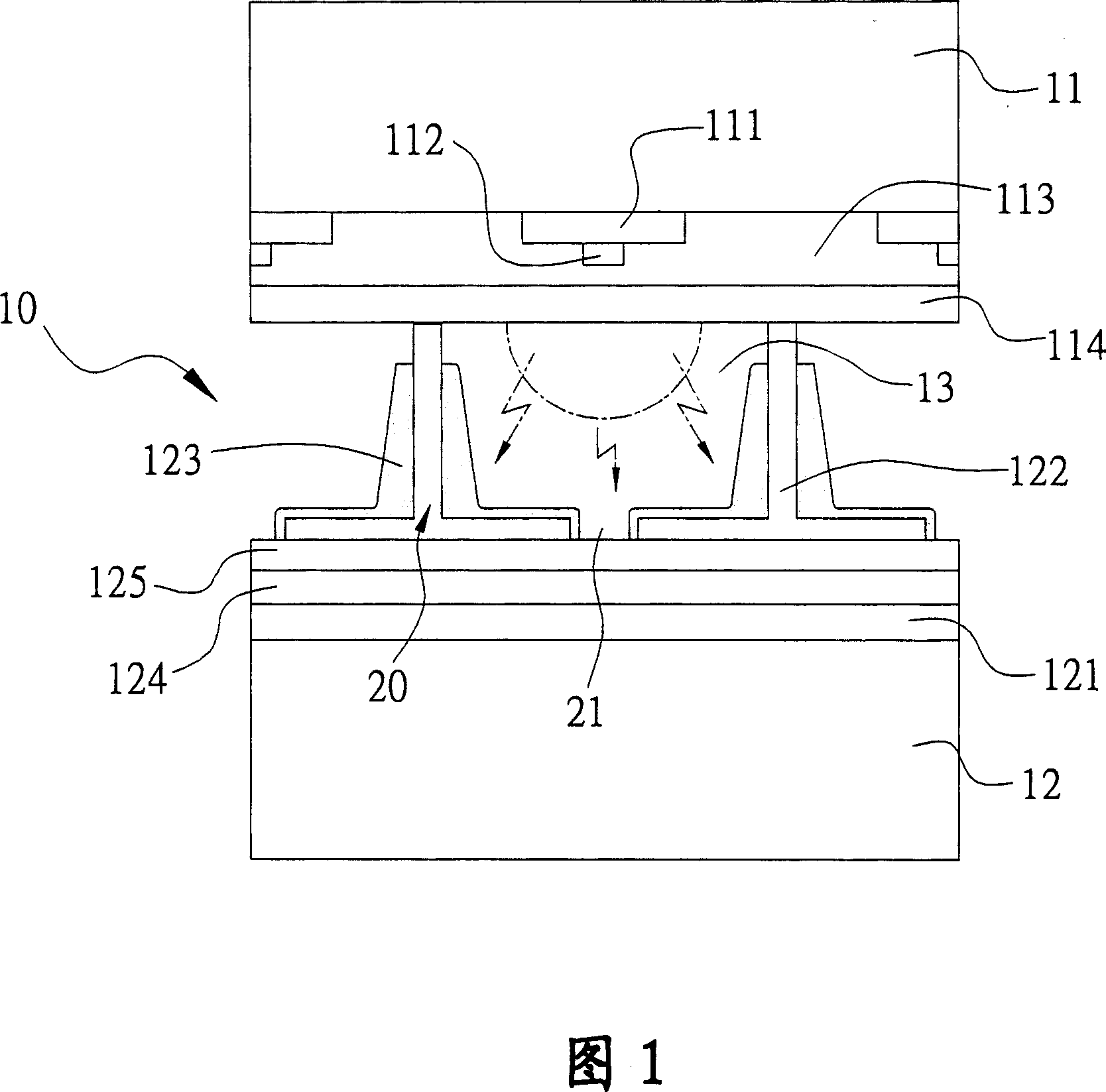

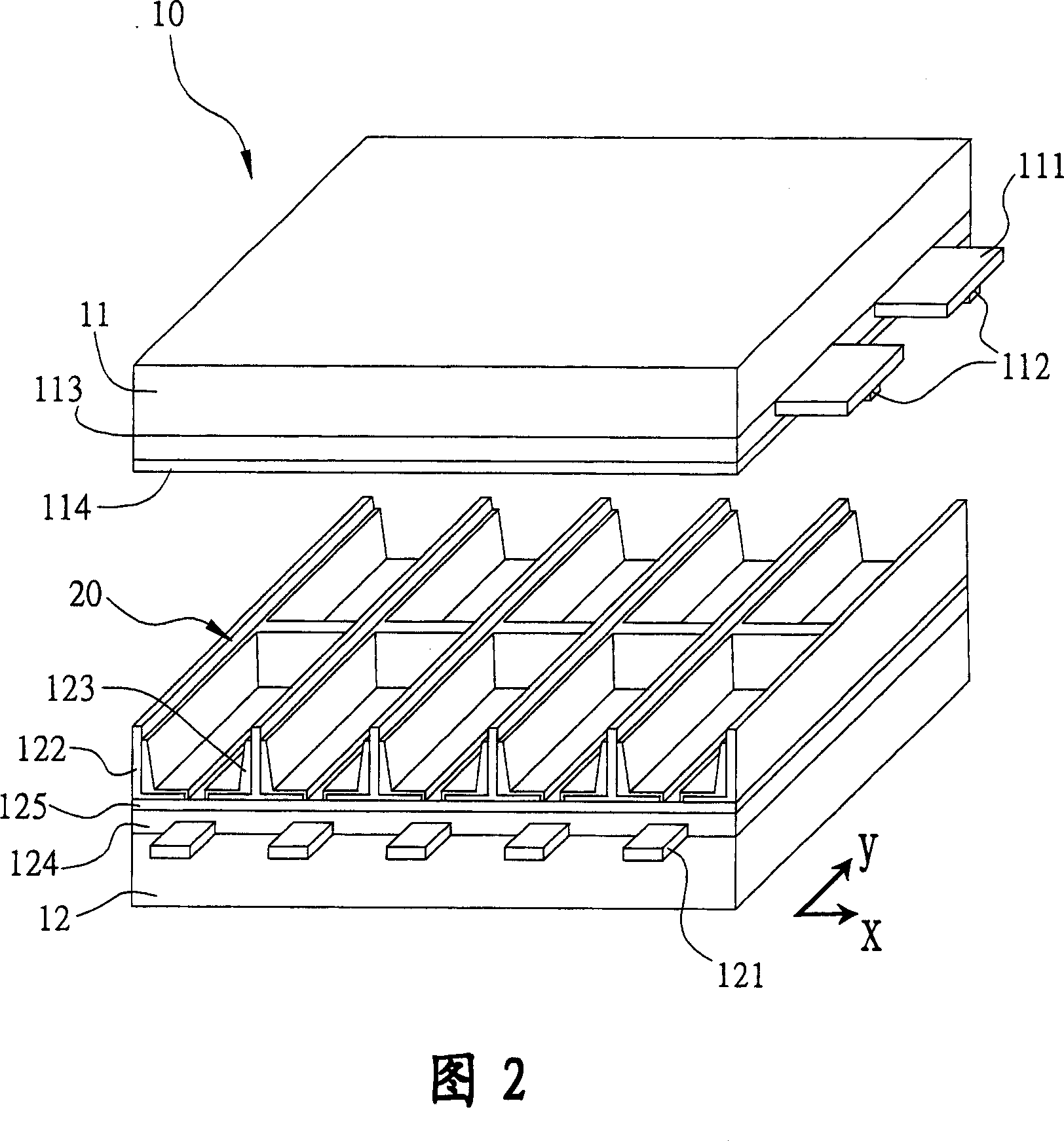

[0031] In order to make the purpose of the present invention, shape, structure device features and its effect easier to recognize and understand, the embodiments are given in conjunction with the drawings, and the detailed description is as follows:

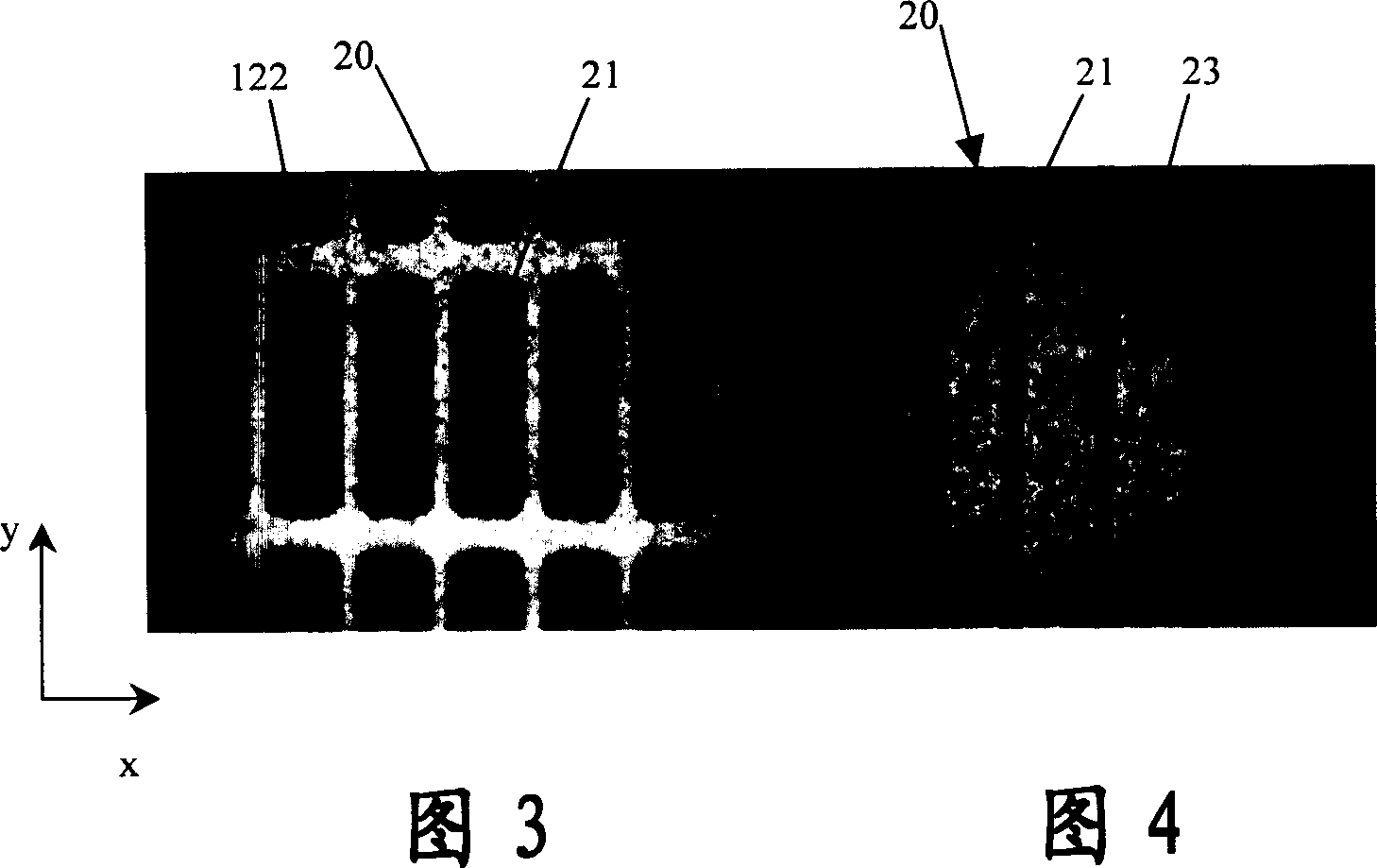

[0032]The invention relates to a manufacturing method of the shadow mask of the opposite discharge type plasma flat display, and the method is used for processing and manufacturing the shadow mask of the opposite discharge type plasma flat display. Before a shadow mask is not processed, as shown in Fig. 6, it is a thin metal plate 40, and the two side surfaces of this metal plate 40 are in a flat state. On one side surface of 40, along the vertical direction and the horizontal direction, a plurality of barrier walls 422 parallel to each other and at equal intervals are respectively etched, wherein a space surrounded by every four adjacent barrier walls 422 is the Facing a discharge cell 43 of the discharge type plasma flat panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com