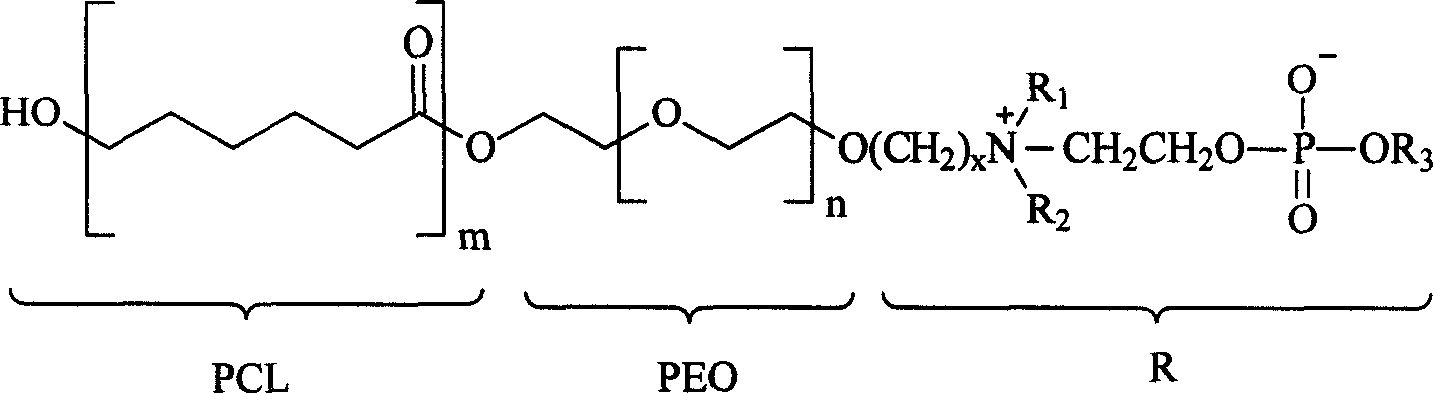

Polycaprolactone-polyethylene glycol block copolymer, and its preparing method and use

A technology of block copolymer and polyethylene glycol, which is applied in the field of biomedical materials, can solve the problems of insufficient durability, poor universality, and cumbersome process of surface modification of materials, so as to avoid chemical reaction steps, quick modification, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the examples, but the description of the examples does not create any limitation on the protection of the present invention.

[0038] 1. Synthesis of PEO segment α-hydroxy-ω-dimethylamino polyoxyethylene ether in PCL-PEO-R:

[0039] Take 30.6 g of dried, redistilled and refined dimethylaminoethanol, add 1.3 g of new sodium to remove surface impurities to react to generate sodium dimethylaminoethoxide solution, put it in a desiccator and seal it for future use.

[0040] Add 14 g of the above-mentioned sodium dimethylaminoethoxide solution (containing 0.5 g of sodium) and 456 g of ethylene oxide (PEO design molecular weight 3000) into a carefully dried stainless steel autoclave equipped with mechanical stirring and internal cooling coils at about 0 ° C. , after purging and replacing the air with nitrogen, seal the reactor, start stirring at a speed of 300rpm, gradually increase the temperature and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com