Method for producing 5-methyl benzotriazole

A technology of tolyltriazole and its production method is applied in the field of manufacture of tolyltriazole, which can solve the problem of difficulty in producing high-purity 5-methylbenzotriazole, difficulty in adapting to high-precision, High stability requirements and other issues, to achieve the effect of easy organization of industrial production, easy control of the preparation process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A kind of production method of 5-methylbenzotriazole of the present embodiment comprises the following steps:

[0025] 1. Add 700kg of pure water to the reaction kettle. The pure water refers to distilled water or deionized water. The pure water in this embodiment is deionized water; 4 Add diaminotoluene into the reaction kettle, and stir, keep the temperature of 95-105°C, dissolve for 30 hours, and make it fully dissolved; the reaction temperature is controlled by the circulating water of the medium pressure coil;

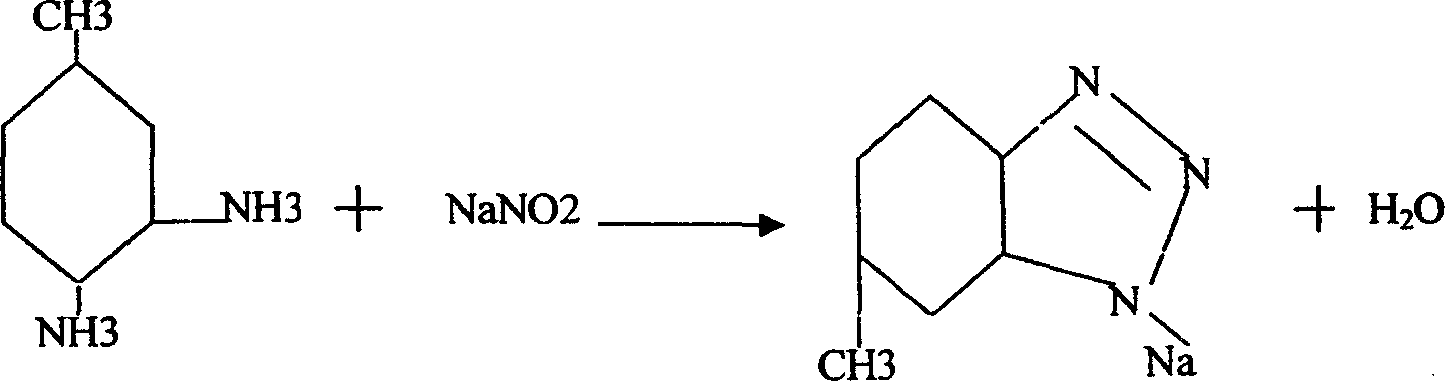

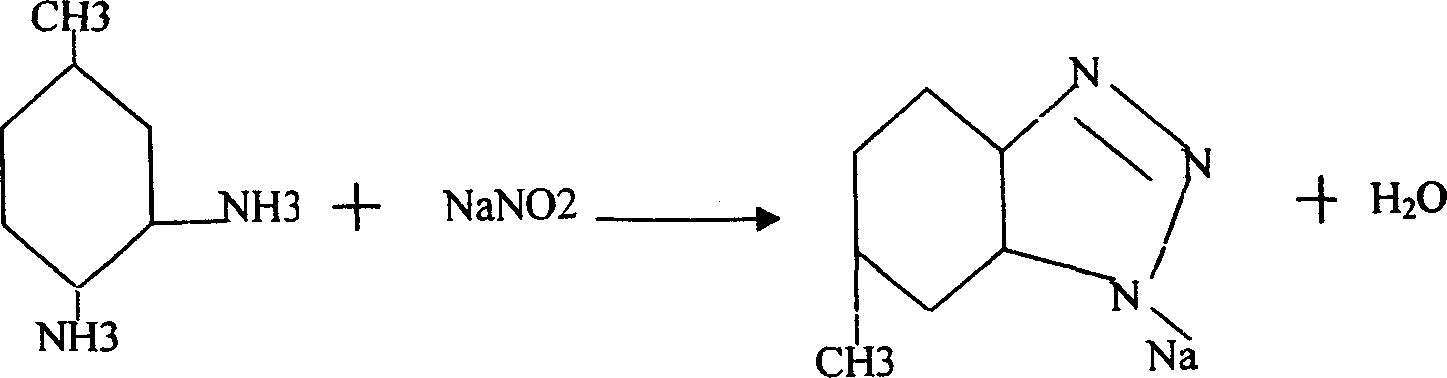

[0026] 2. Add 380kg of sodium nitrite to the reaction kettle solution formed in step 1, and stir for 3 hours; the reaction pressure is kept at 5.6MPa, and the temperature is kept at 280°C; the reaction formula is:

[0027]

[0028] 3. Cool the solution formed in step 2 to a temperature of 180°C and reduce the pressure to 0.7MPa;

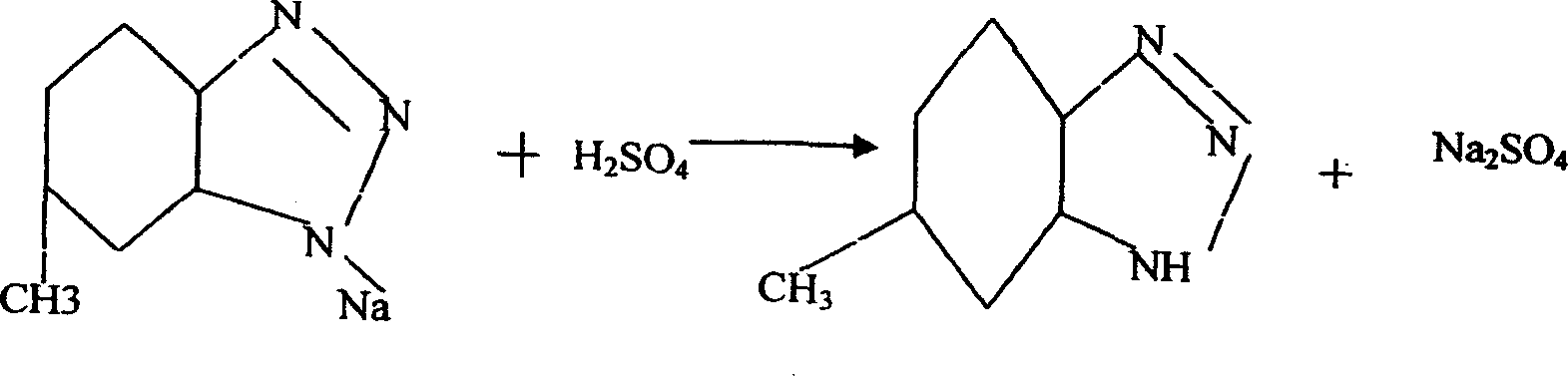

[0029] 4, drip the sulfuric acid of 13% (w / w) in the solution formed in step 3, keep pH value 5, a large amount of crystals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com