Ultrasonic cleaning method and apparatus

A cleaning device and ultrasonic technology, applied in the field of ultrasonic cleaning, can solve the problems of killing activated sludge microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

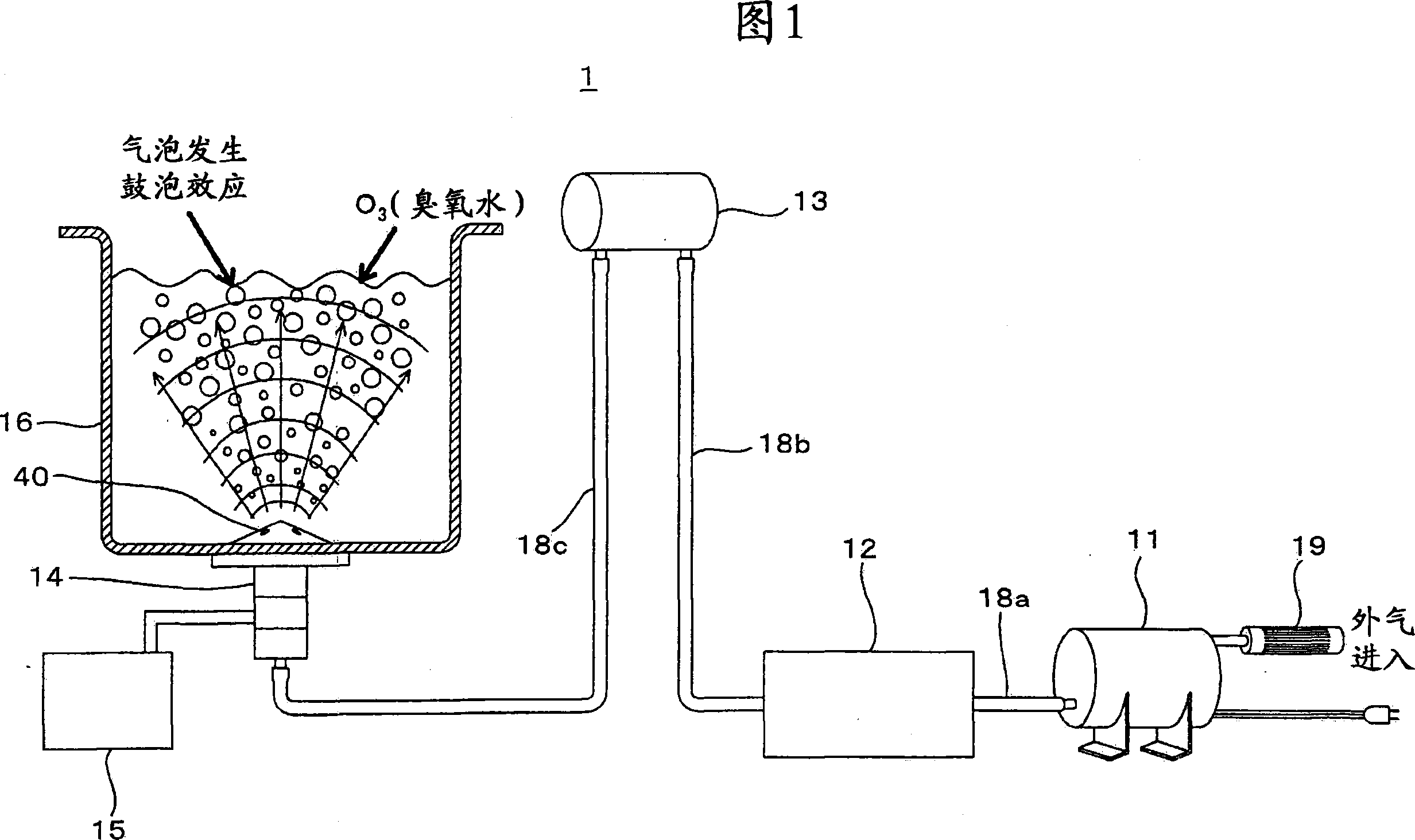

[0078] The cleaning tank 16 adopts an internal volume of 500 x 300 x 140 mm in depth, and injects 15 liters of water therein. Ultrasonic transducers 14 are provided with 4×2 25 kHz transducers on the bottom of the cleaning tank, and 3 50 kHz transducers on both sides, totaling 14 ultrasonic transducers 14 . That is to say, ultrasonic cleaning is performed by shear action accompanied by traveling wave impact interference from three aspects of independent vibration causing radial dispersion, horizontal and vertical interference, and phase angle consideration.

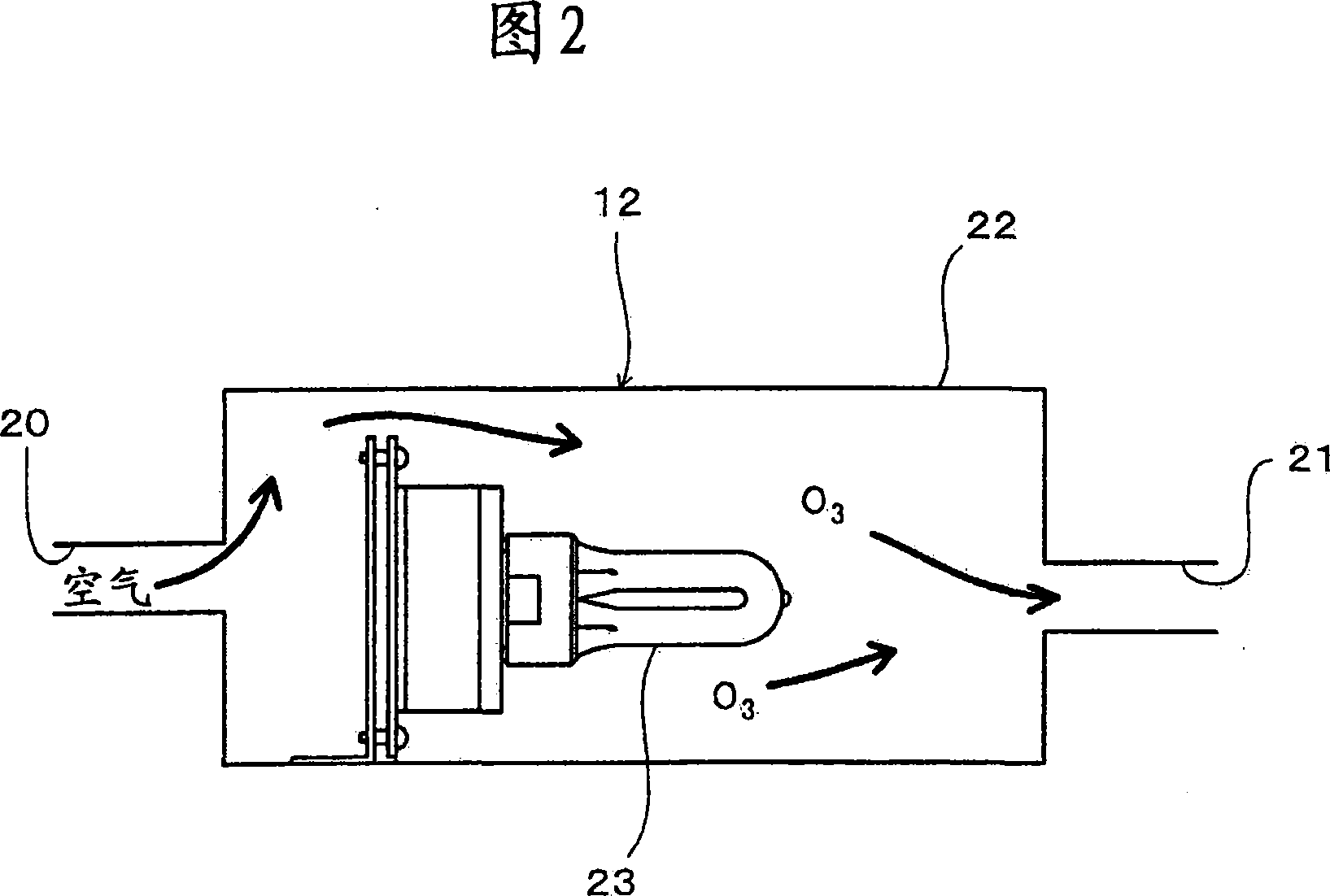

[0079] Air containing ozone is fed through the communication path 42 of the ultrasonic transducer 14 , and microbubbles excited by ultrasonic waves are sent into the tank from the discharge port 40 .

[0080] As non-pathogenic microorganisms, E. coli was selected from JM109 strain, and budding yeast was obtained from FY24 strain of S288C strain; as sterilization operations, four methods of ozone, ozone and ultrasonic, cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com