Cooling structure of solid thin-sheet laser

A thin-film laser, cooling structure technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of large temperature gradient and explosion of laser medium, achieve good cooling effect, reduce deformation, and high heat transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

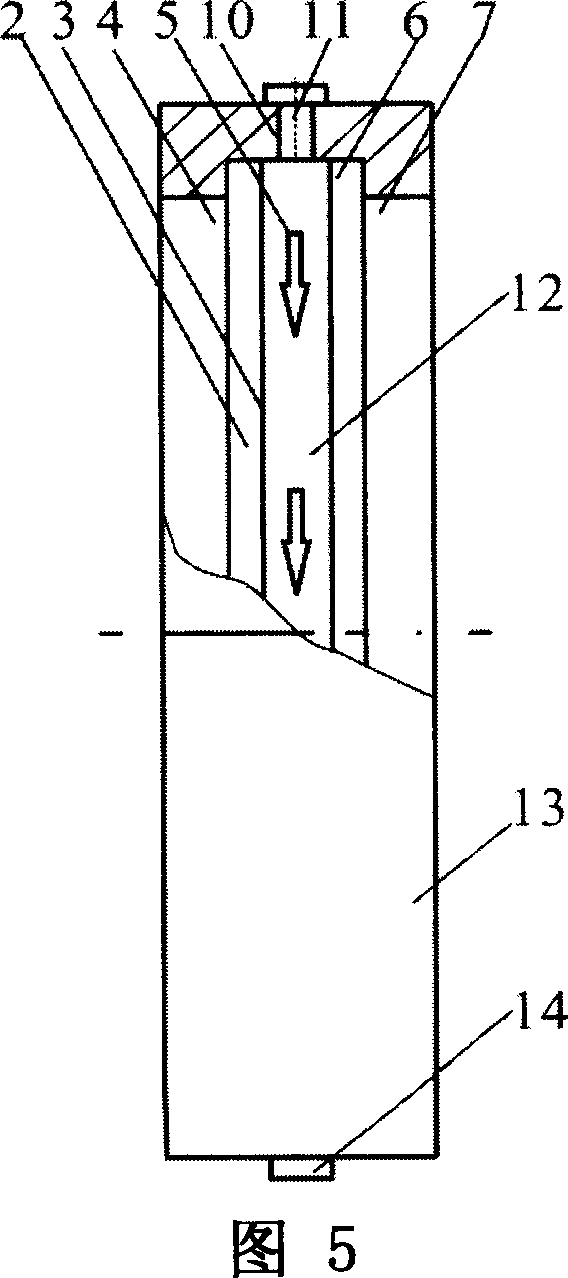

[0033] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

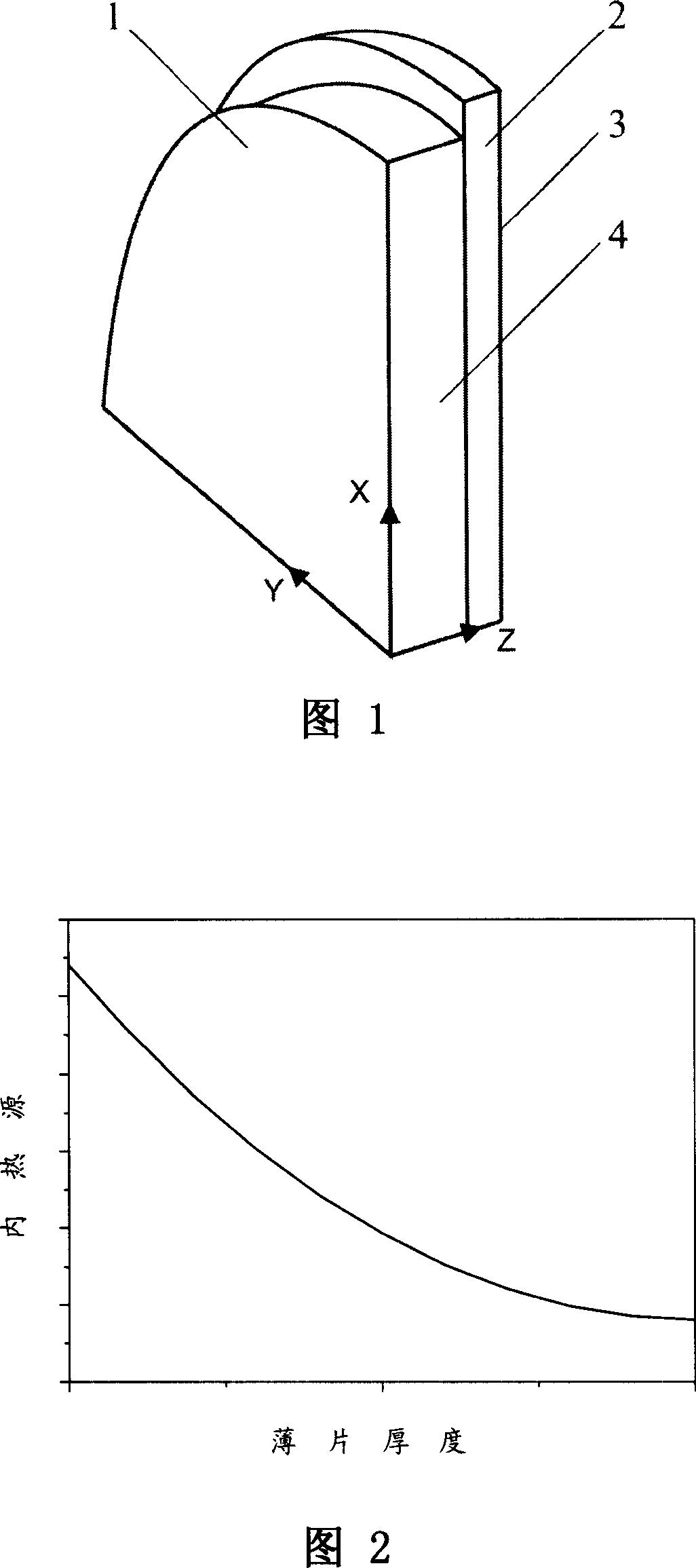

[0034] Referring to Fig. 4 and Fig. 5, Fig. 4 is an overall schematic diagram of the double sheet laser medium and diamond heat sink solid-state laser structure of the present invention, and Fig. 5 is a partial cross-sectional schematic diagram of an embodiment of the cooling structure of the present invention. As can be seen from Fig. 4, the cooling structure of the solid-state thin-film laser of the present invention is composed of a plurality of modules, wherein the composition of each module includes:

[0035] 1) Two pieces of left sheet laser medium 4 and right sheet laser medium 7 with the same size and performance, placed parallel and spaced apart. You can choose Yb:YAG crystal or Nd:YAG crystal flakes, or other laser media suitable for use as flake lasers. On the outer sides of the left sheet laser medium 4 and the right sheet l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com