Micro-oil plasma composite ignition and combustion-stabilization method and device therefor

A plasma point and plasma technology, which is applied in the ignition field during the start-up and stable combustion of pulverized coal boilers of thermal power generation units, can solve the problems of affecting fuel saving effect, failure of arc ignition, easy oxidation damage of plasma generators, etc., and achieves improvement The effect of comprehensive economic benefits, reducing electrode loss rate, and reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

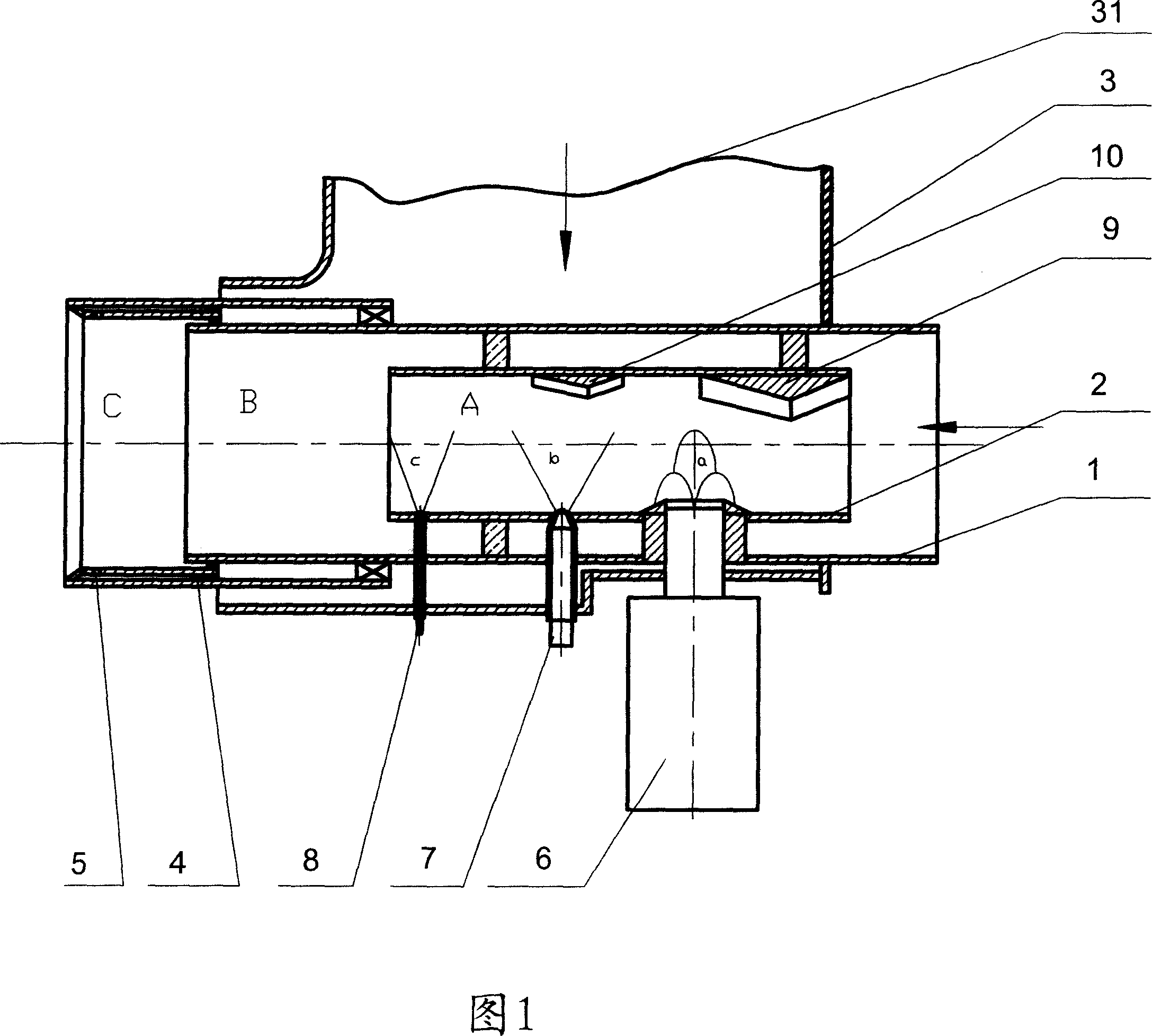

[0016] As shown in Figure 1, the device used in the micro-oil plasma composite ignition and stable combustion method of the present invention includes a primary air pipe 1, a combustion pipe 2, a perimeter air box 3, a film cooling air duct 4, and an anti-coking air duct arranged in the boiler burner. The tuyere 5, the combustion pipe 2 are concentrically arranged in the inner cavity of the primary air pipe 1 and the axial length of the combustion pipe 2 is smaller than the axial length of the primary air pipe 1, and the two ends of the combustion pipe 2 are connected to the corresponding two ends of the primary air pipe 1 There is a certain distance between them, the first-stage combustion chamber A is formed in the inner cavity of the combustion pipe 2, the second-stage combustion chamber B is formed between the end of the combustion pipe 2 and the end of the primary air pipe 1, and the third-stage combustion chamber is formed outside the primary air pipe 1. Level combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com