Circumfluence type film separation device for carbon dioxide recovery and condensation

A carbon dioxide and membrane separation technology, applied in the field of gas absorption and membrane separation engineering, which can solve the problems of high energy consumption and large equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

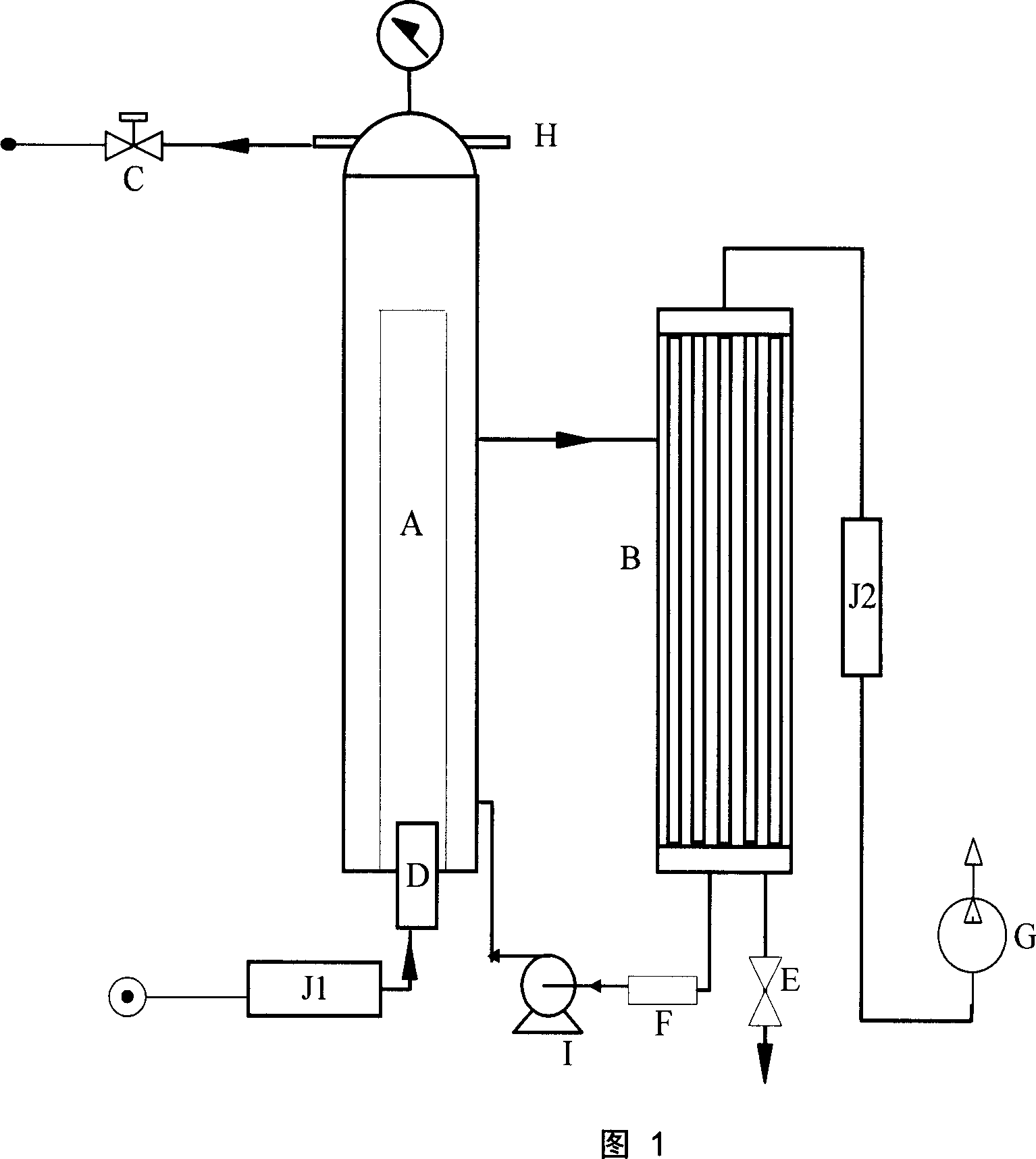

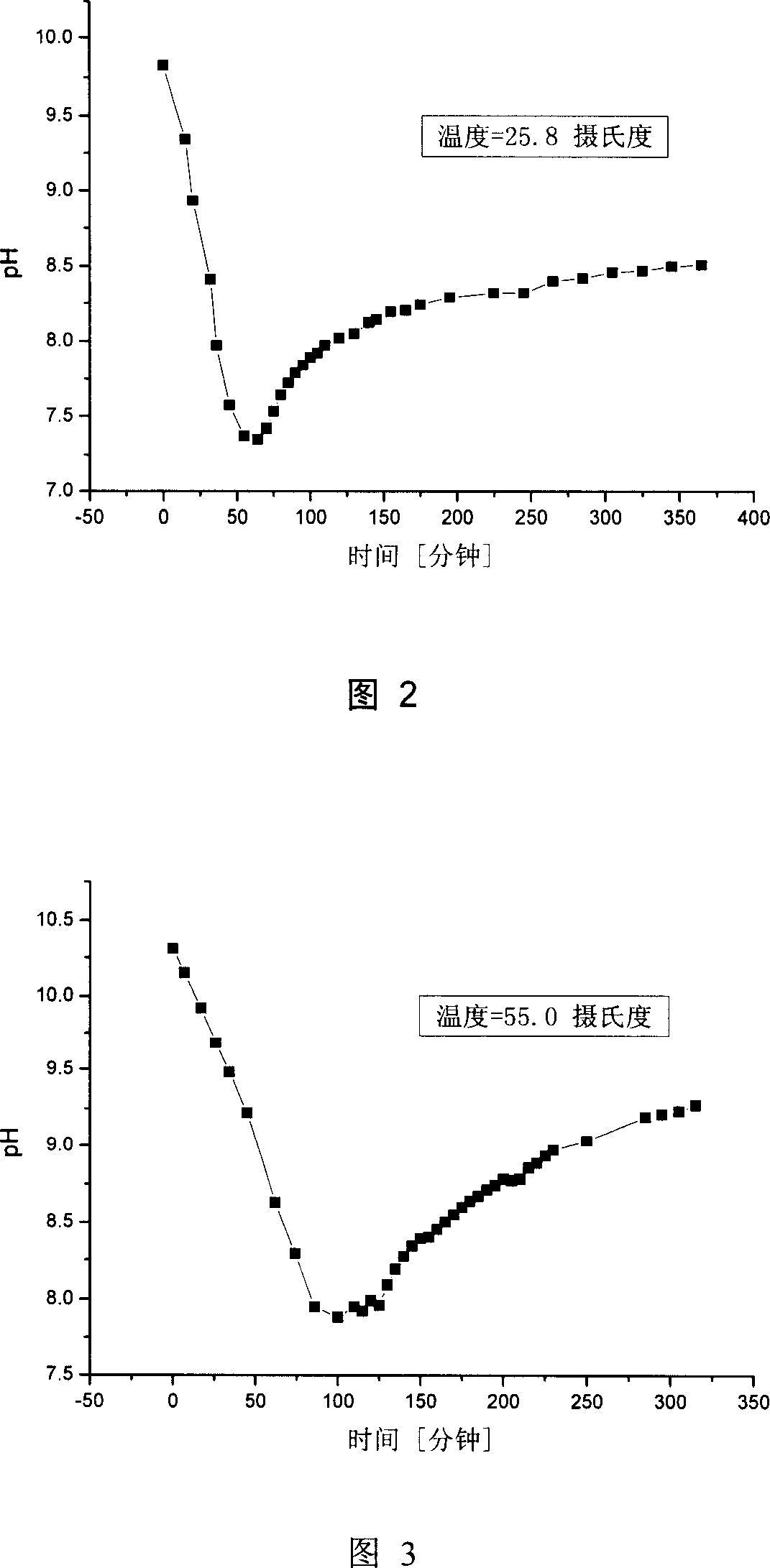

[0022] Example 1: Using a loop bubbling reactor as a carbon dioxide absorption device, using a hollow fiber membrane element as a carbon dioxide desorption membrane contactor, according to the process shown in Figure 1, using monoethanolamine as a carbon dioxide absorbent, and successively carrying out carbon dioxide absorption and desorption experiments . After the absorption liquid is saturated (the pH value is stable), the carbon dioxide desorption experiment is carried out in the membrane contactor at room temperature, and the relationship between the pH and temperature of the absorption liquid with time is measured (Figure 2). As shown in the figure, after the desorption operation starts, the pH value of the solution rises gradually, and the desorption effect is obvious.

Embodiment 2

[0023] Example 2: Using a loop bubbling reactor as a carbon dioxide absorption device, using a hollow fiber membrane element as a carbon dioxide desorption membrane contactor, according to the process shown in Figure 1, using monoethanolamine as a carbon dioxide absorbent, and successively carrying out carbon dioxide absorption and desorption experiments . After the absorption liquid is saturated (the pH value is stable), the carbon dioxide desorption experiment is carried out in the membrane contactor under the condition of elevated temperature, and the relationship between the pH and temperature of the absorption liquid with time is measured (Figure 3). As shown in the figure, after the operation starts, the pH value of the solution rises gradually, and the desorption effect is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com