Tungsten desorption method of weakly basic anion exchange resin

A weakly basic anion and exchange resin technology, applied in the direction of ion exchange, ion exchange regeneration, chemical instruments and methods, etc., can solve the problems of difficult control of impurity elements, affecting desorption flow rate, long desorption cycle, etc., to reduce the amount of washing water , Simplify the desorption process, improve the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below. The embodiments described with reference to the accompanying drawings are exemplary. The embodiments of the present invention are described in detail below.

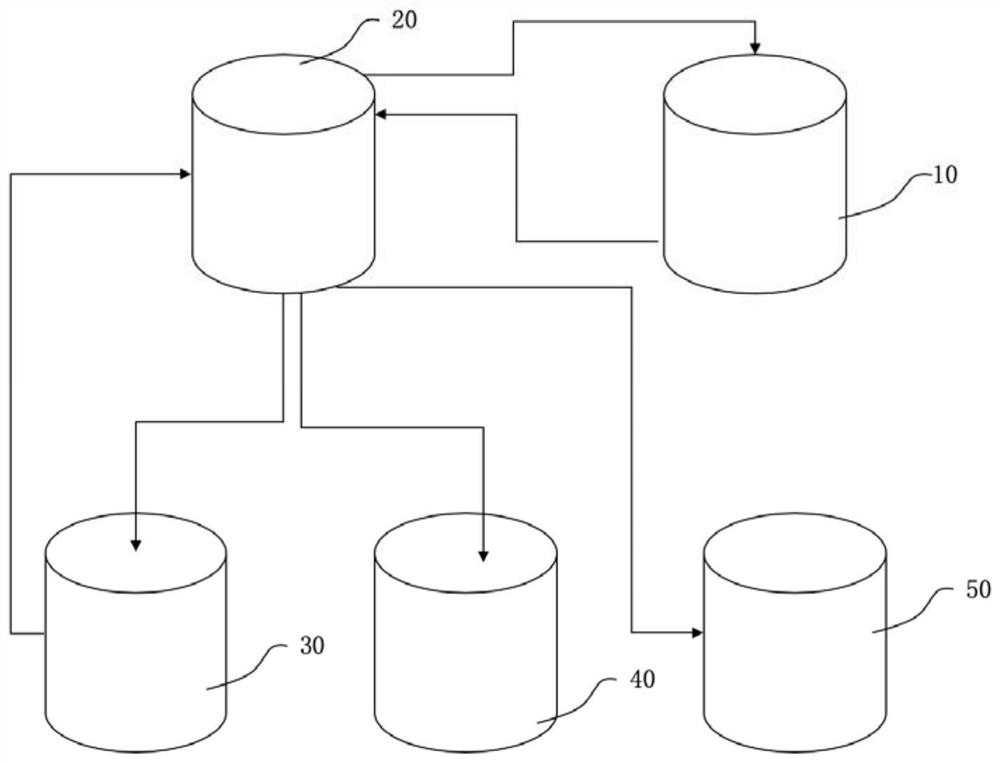

[0025] Reference below figure 1 with figure 2 Describe the tungsten solution method of weakly basic anion exchange resin according to an embodiment of the present invention.

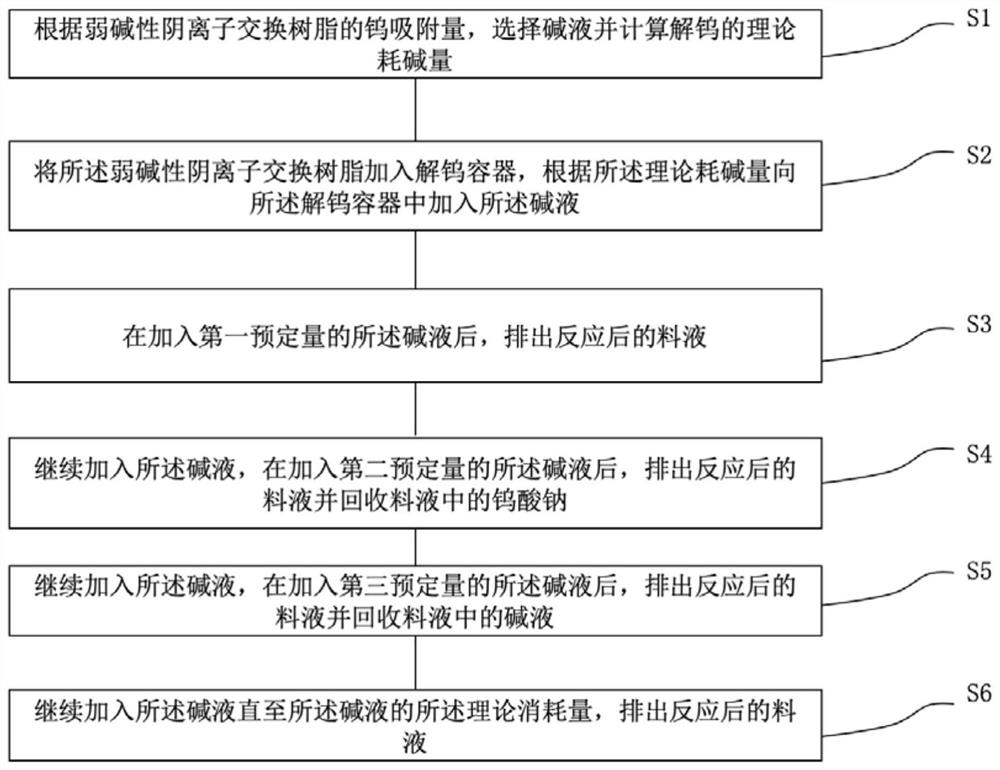

[0026] First, like figure 1 As shown, the method for removing tungsten from a weakly basic anion exchange resin according to an embodiment of the present invention includes the following steps:

[0027] S1. According to the tungsten adsorption capacity of the weakly basic anion exchange resin, select the alkali solution and calculate the theoretical alkali consumption for tungsten solution.

[0028] S2. Add the weakly basic anion exchange resin to the tungsten solution container, and add the alkali solution to the tungsten solution container according to the theoretical alkali ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com