Aminocellulose and application thereof

A technology of cellulose and cellulose sulfate, applied in other chemical processes, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of unfavorable industrial production and application, high price, difficult to obtain, etc., and achieve the effect Good, low-cost, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

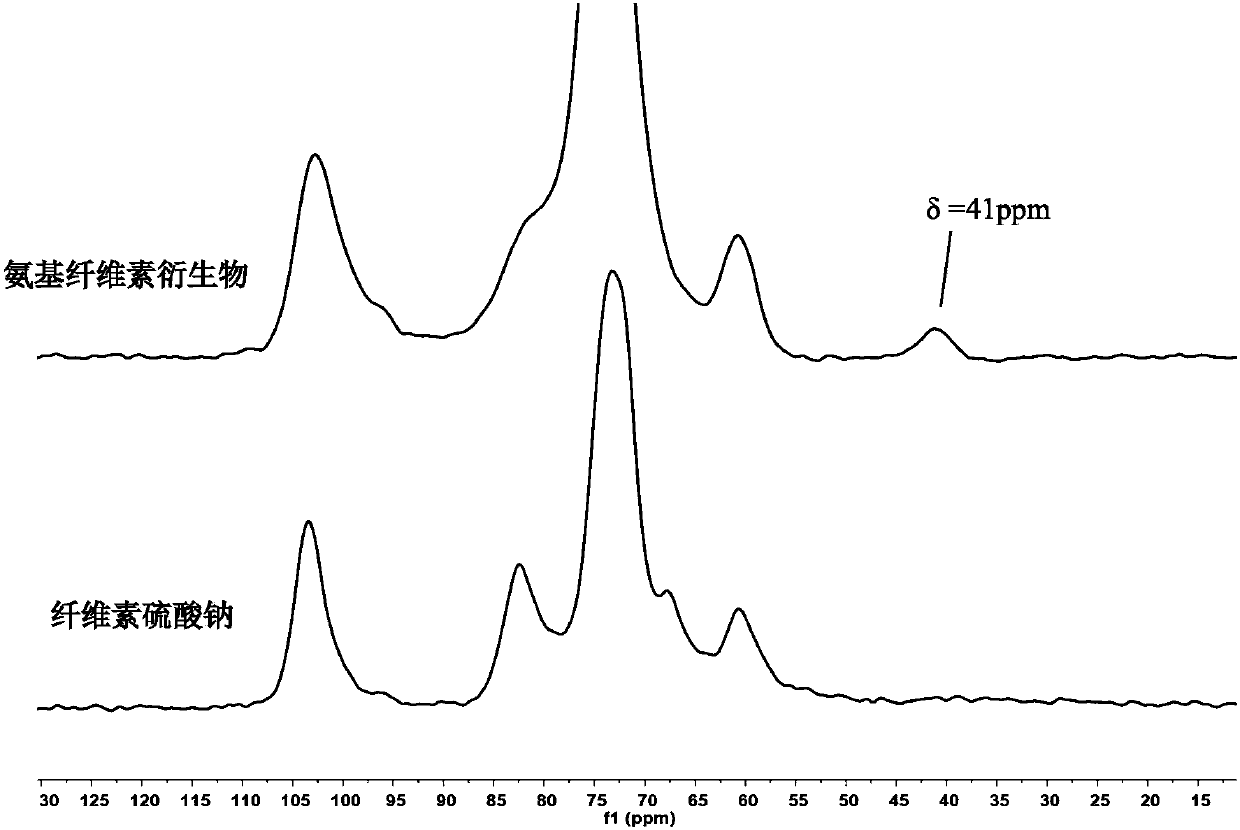

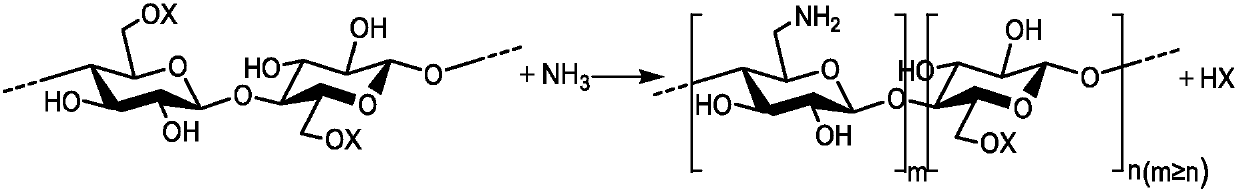

[0024] Add cellulose sodium sulfate and 25% ammonia water into the autoclave at a molar ratio of 1:5, seal it quickly, and react at 180° C. with self-boosting constant temperature stirring for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, a solid was formed during the reaction, the solid-liquid was separated to separate the filter cake, and dried at 80° C. to constant weight. The product was found by nuclear magnetic analysis, and a new peak appeared at δ=41ppm, which was -CH after consulting 2 Chemical shift of -N-; N content determined by elemental analysis DS = 1.31. Comprehensive analysis of the NMR C spectrum and N content of the product can confirm that the method in this study was used to successfully replace the amino group of sodium cellulose sulfate.

Embodiment 2

[0026] Add cellulose sodium sulfate and 25% ammonia water into the autoclave at a molar ratio of 1:5, seal it quickly, and react at 180° C. with self-boosting constant temperature stirring for 6 hours. After the reaction was completed, it was naturally cooled to room temperature, a solid was formed during the reaction, the solid-liquid was separated to separate the filter cake, and dried at 80° C. to constant weight. The product was found by nuclear magnetic analysis, and a new peak appeared at δ=41ppm, which was -CH after consulting 2 Chemical shift of -N-; DS = 1.09 determined by elemental analysis for N content. Comprehensive analysis of the NMR C spectrum and N content of the product can confirm that the method in this study was used to successfully replace the amino group of sodium cellulose sulfate.

[0027] Apply the prepared amino group-containing cellulose derivatives to the adsorption of heavy metal ions:

Embodiment 3

[0029] Add the aminocellulose (DS=1.31) prepared in Example 1 of the present invention into the lead ion solution, stir and adsorb, and after reaching the adsorption equilibrium, analyze the concentration of heavy metals in the solution before and after adsorption, and measure the concentration of ion adsorption in the aminocellulose solution. The rate is 81.6%. The aminocellulose that adsorbs lead ions is desorbed, and the specific process is as follows: soak the aminocellulose that adsorbs lead ions obtained by filtration with a small amount of 1% HCl for 30 minutes, filter, and then soak the filter cake with a small amount of 1% NaOH for 30 minutes Filter, then wash the filter cake with distilled water until it is neutral, dry it at 60°C and then recycle it. The adsorption effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com