High strength machine parts and shaft excellent in fatigue characteristics, and method for improving fatigue characteristics thereof

A technology for fatigue characteristics and mechanical parts, applied in the field of high-strength mechanical parts, which can solve problems such as difficulty in imparting large compressive residual stress, limitation of pellet size, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

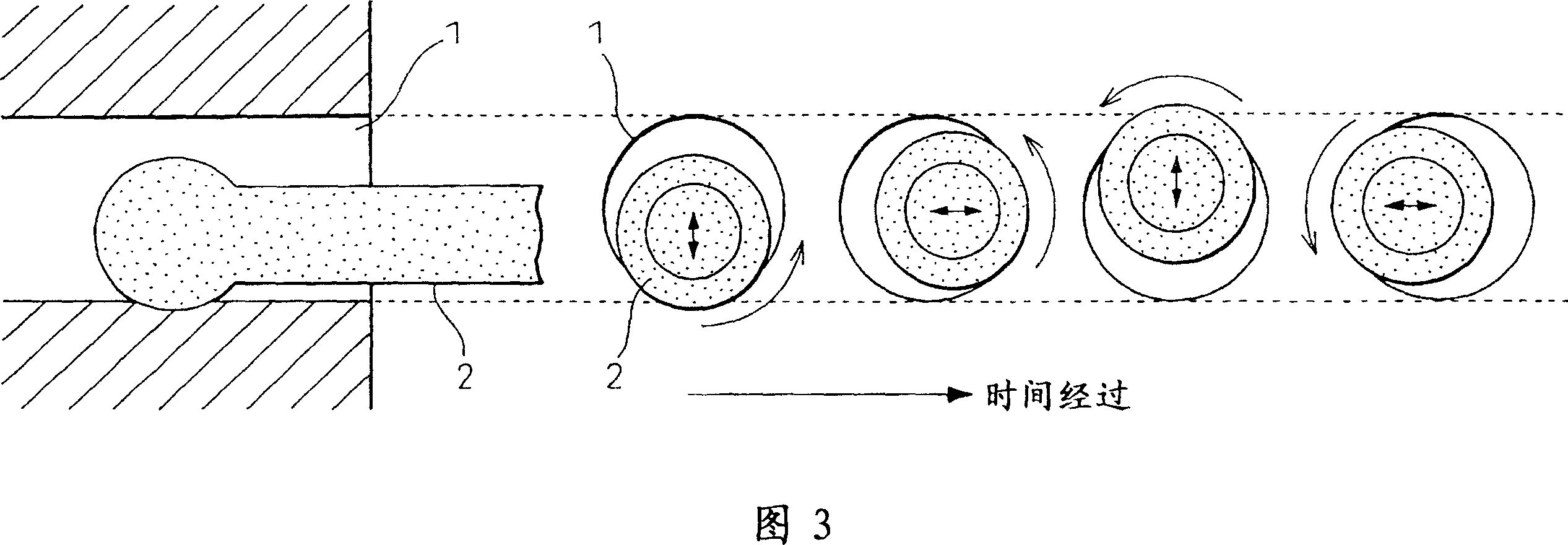

Method used

Image

Examples

Embodiment 1

[0071] Hereinafter, the effects of the present invention will be more specifically described through examples.

[0072] Using steel materials with chemical compositions shown in Table 1, round bar-shaped members (shafts) as shown in FIG. 1 were produced by hot forging. The hot forging temperature is 1200°C. Then, by machining, it is finished into a mechanical part having notches shown in FIG. 1 . Then, using these machine parts, quenching-tempering treatment, high-frequency heating treatment, and carburizing treatment were performed, and the HV hardness of the surface was measured. The quenching-tempering treatment is carried out under conditions of a quenching temperature of 850 to 950°C and a tempering temperature of 180 to 650°C. The high-frequency heating treatment is quenching after heating to 950°C, and then tempering at 150°C. The carburizing treatment was carried out at a carburizing temperature of 950°C and a tempering temperature of 160°C. In addition, ultrasonic...

Embodiment 2

[0083] From the steel with the composition shown in Table 3, cut out a "Ono-type rotary bending test piece with a round hole" with a through hole to simulate an oil hole. The size of the test piece, the diameter of the parallel zone d = 12mm (JIS Z-2274, No. 1 Test piece, symbol 1-12), the diameter of the through hole is 2.4mm.

[0084] A test piece subjected to the ultrasonic treatment of the present invention and a comparison material without treatment or a treatment outside the range were prepared, and the Ono-type rotating bending fatigue test was performed to obtain fatigue strength. The results are shown in Table 4.

[0085] In addition, since this test piece is used in a simple bending fatigue test, fatigue cracks are generated from the surface layer of the hole, and fracture occurs on a surface perpendicular to the axial direction, so ultrasonic treatment is performed on the entire circumference of the surface layer around the hole.

[0086] The measured values of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com