Cadmium sulfide bare quantum spot and preparation process

A technology of quantum dots and cadmium sulfide, applied in the field of cadmium sulfide bare quantum dots and its preparation, can solve the problems of semiconductor nanocrystals losing practical application value, unrevealed data or maps, flammable raw materials, etc., to avoid toxicity and high cost , good fluorescence emission peak shape, perfect crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Measure 0.05 (mol / L) cadmium acetate 60ml and 0.05 (mol / L) L-cysteine 50ml according to the ratio of 1.2 and mix them in the autoclave liner (the concentration of cadmium acetate in the reaction system is 27mmol / L, the reaction concentration of L-cysteine is 22.5mmol / L), and be 1mol / L potassium hydroxide solution to regulate the acidity and alkalinity of solution with concentration, make it pH be 11. The autoclave was sealed, heated and pressurized to 130° C., and magnetically stirred. The high temperature stage is kept warm for 7 hours. cooling down naturally

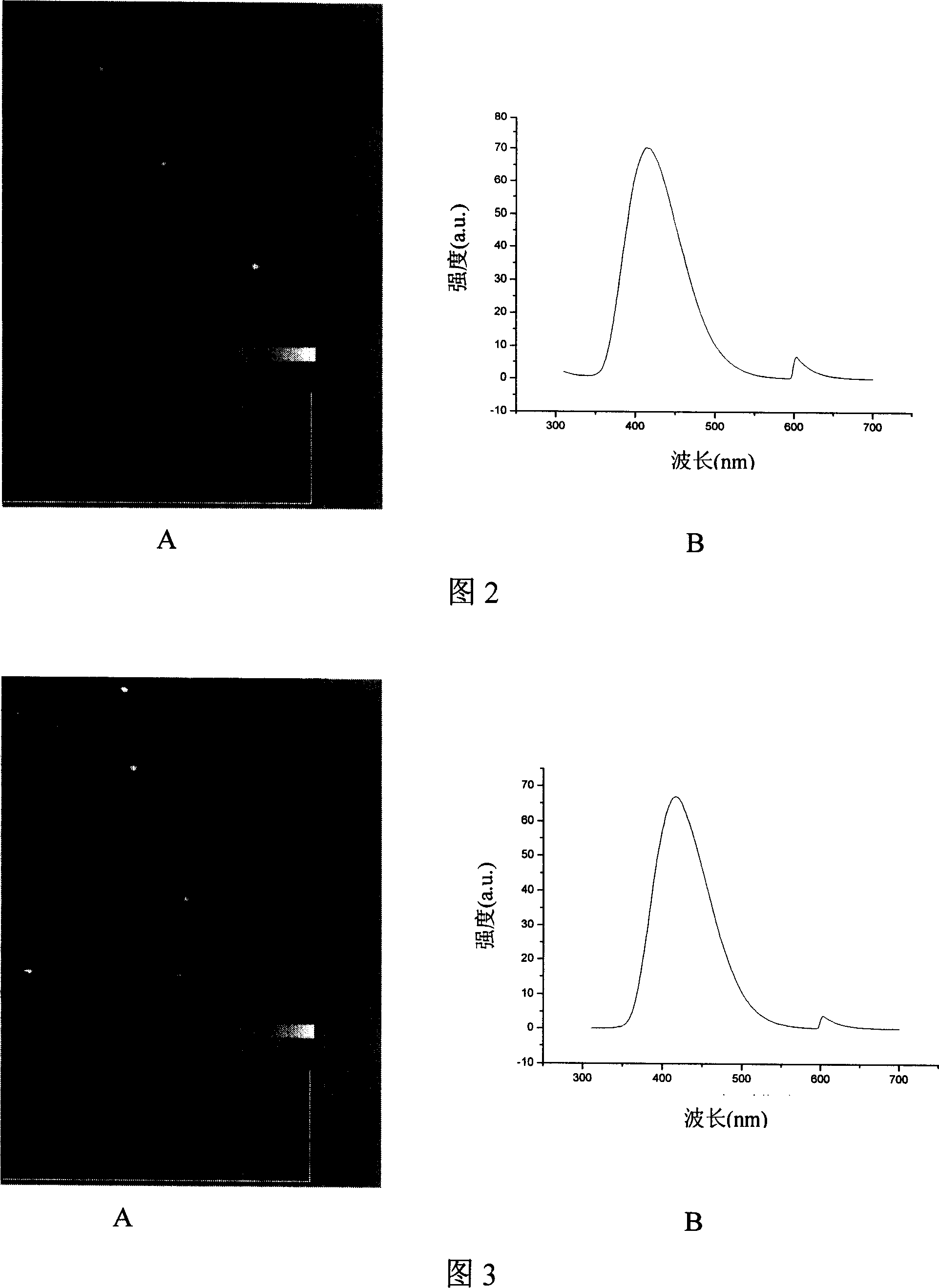

[0027] And after ensuring that the pressure in the autoclave drops to normal pressure, open the lid of the autoclave, transfer the material in the autoclave to a ground bottle, and store it away from light. Obtained product characterization data: atomic force microscope (AFM) photos and fluorescence emission spectra are shown in Figure 2, the size of the cadmium sulfide quantum dots is about 6.6nm, λmax i...

Embodiment 2

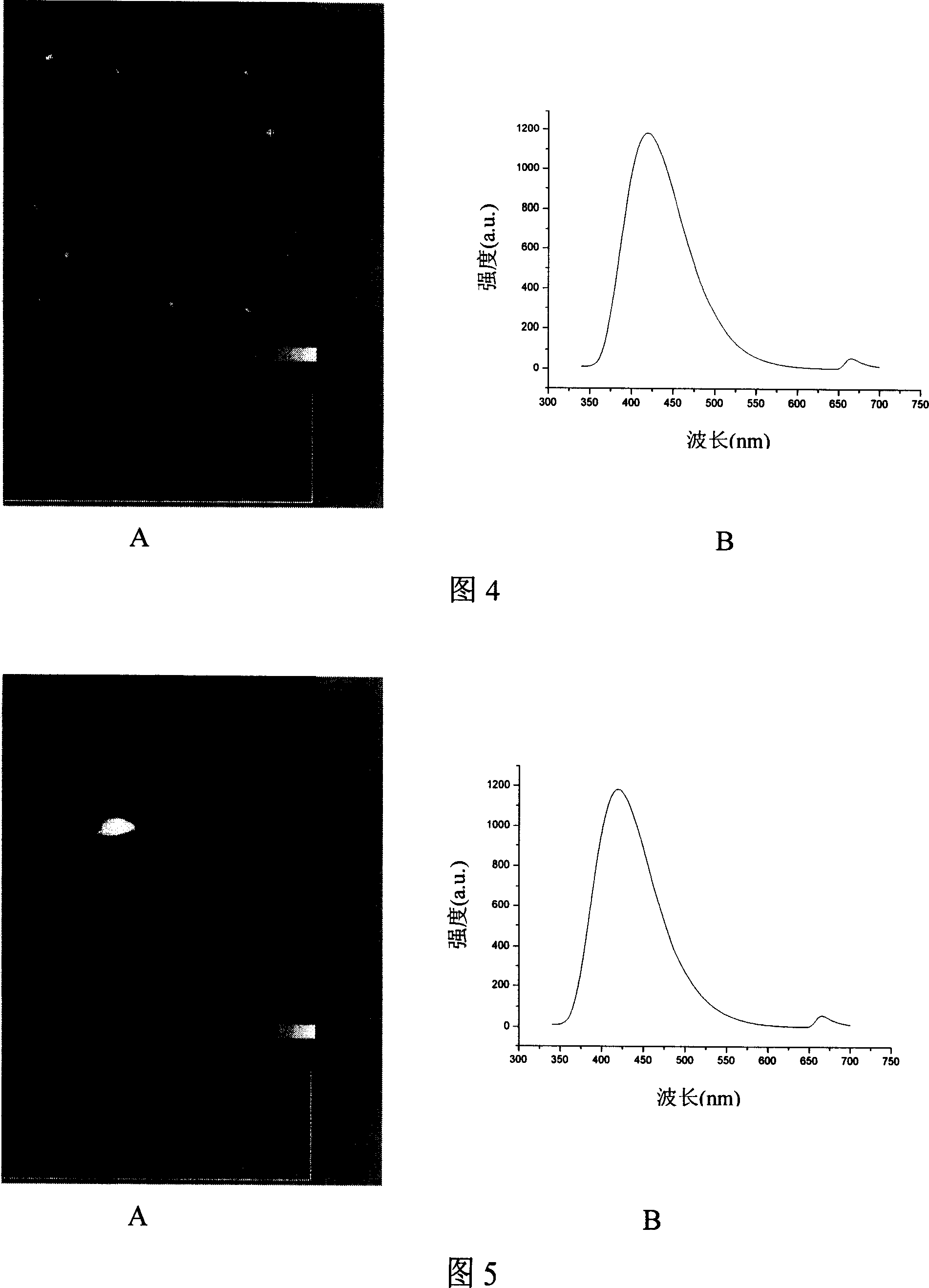

[0029] Measure 0.05 (mol / L) cadmium acetate 60ml and 0.05 (mol / L) L-cysteine 60ml according to 1 and mix them in the liner of the autoclave (the concentration of cadmium acetate in the reaction system is 25mmol) / L, the reaction concentration of L-cysteine is 25mmol / L), and be 1mol / L potassium hydroxide solution with concentration to regulate the acidity and alkalinity of solution, make it pH be 12. The autoclave was sealed, heated and pressurized to 130° C., and magnetically stirred. The high temperature stage is kept warm for 7 hours. After cooling down naturally and ensuring that the pressure in the autoclave drops to normal pressure, open the lid of the autoclave, transfer the materials in the autoclave to a ground bottle, and store in the dark. Obtained product characterization data: atomic force microscope (AFM) photos and fluorescence emission spectra are shown in Figure 3, the size of the cadmium sulfide quantum dots is 2.0nm, λmax is 416nm, and the half-peak widt...

Embodiment 3

[0031] Measure 60ml of 0.10 (mol / L) cadmium acetate and 50ml of 0.10 (mol / L) L-cysteine according to the ratio of Cd / S of 1.2 and mix them in the liner of the autoclave (the concentration of cadmium acetate in the reaction system is 54.5 mmol / L, the reaction concentration of L-cysteine is 45.4mmol / L), and with a concentration of 1mol / L potassium hydroxide solution, the pH is adjusted to be 12. The autoclave was sealed, heated and pressurized to 130° C., and magnetically stirred. Keep warm for 6 hours in the high temperature stage. After cooling down naturally and ensuring that the pressure in the autoclave drops to normal pressure, open the lid of the autoclave, transfer the materials in the autoclave to a ground bottle, and store in the dark. Obtained product characterization data: Atomic force microscope (AFM) photo and fluorescence emission spectrum are shown in Figure 4, the size of the cadmium sulfide quantum dots is 4.998nm, 10.469nm, the latter is about twice the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com