Process for preparing benzaldehyde and benzoic acid by methylbenzene gas-solid phase catalytic oxidation and micro reactor

A catalytic oxidation and micro-channel reactor technology, applied in the field of petrochemical product synthesis, can solve problems such as the increase in selectivity of benzaldehyde, and achieve the effects of improving the utilization rate of raw materials, high safety, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] 1, embodiment a and comparative example b, c, d, e

[0038] Table 1 illustrates the advantages of the method described in the present invention compared to other methods.

[0039] example

Embodiment a

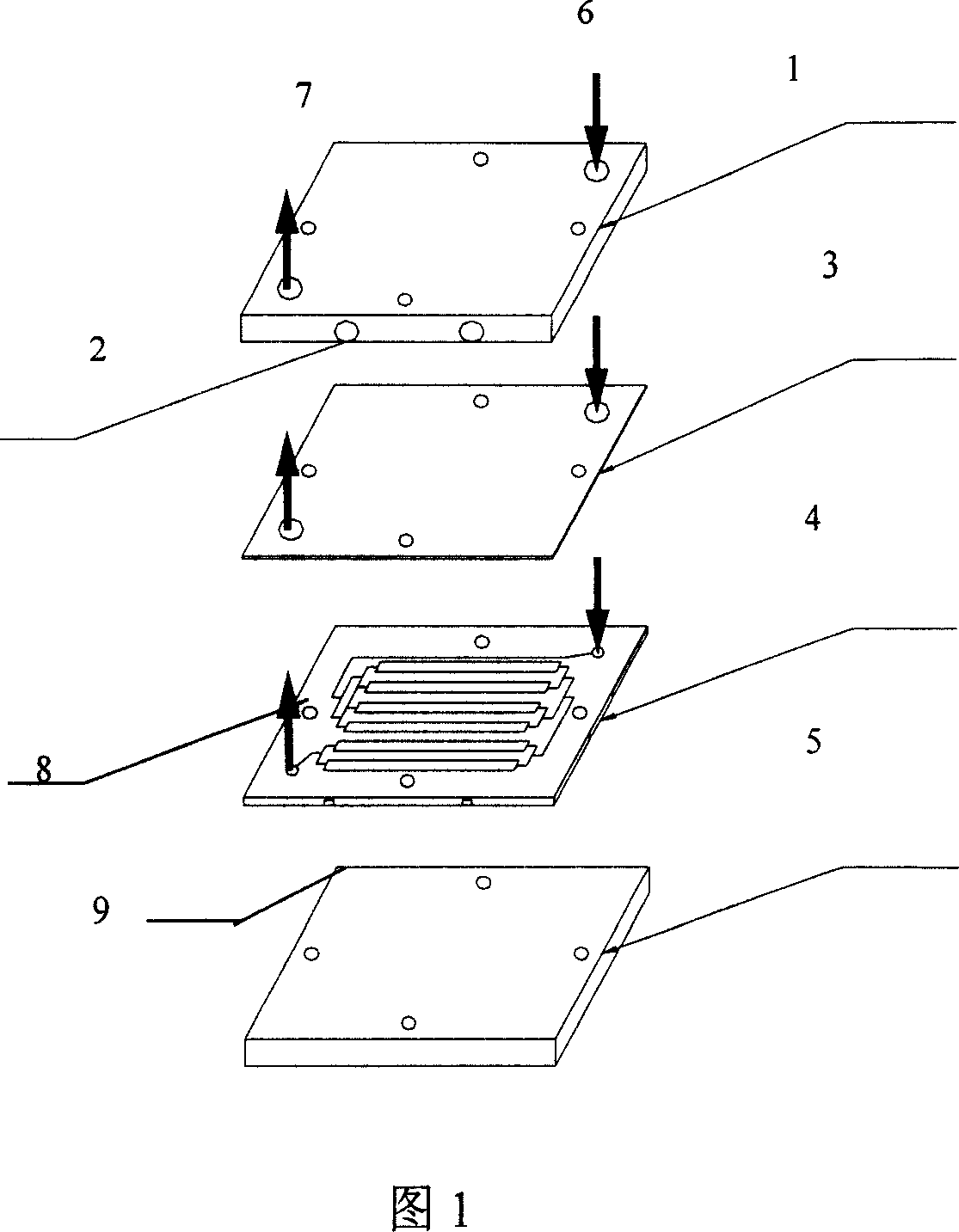

[0040] Embodiment a: Catalyst is the V / TiO that has added Ag promoter 2 Catalyst, the reaction is carried out in the microreactor shown in Figure 1, the catalyst is not diluted, and pure oxygen is used as the oxidant.

Embodiment 1--7

[0047] The selected V / TiO with silver as auxiliary agent in the present invention 2 The catalyst has higher reactivity and product selectivity at the same time, and is the most economical and efficient.

[0048] Table 2 has listed operating conditions and reaction performance and characteristics of the present invention. The catalyst is the particularly preferred AgV / TiO 2 , V 2 o 5 The supported amount was 5.0 wt%, and the Ag / V atomic ratio was 0.5.

[0049] Example

temperature

o 2 / toluene

X

BAc

BA

℃

h -1

%

1

2

3

4

5

6

7

360

360

360

360

330

380

360

3.6

3.6

1.68

8.03

3.86

3.86

3.86

15870

47589

31000

31000

31000

31000

31000

27.0

14.4

11.7

23.7

7.7

36.2

19.3

44.4

36.8

38.1

29.1

28.3

25.7

37.3

29.2

41.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com