Wall adhesive powder

A wall and rubber powder technology, applied in the direction of adhesives, adhesive types, inorganic adhesives, etc., can solve problems such as water seepage, hollowing, poor adhesion, etc., to reduce environmental pollution, reduce costs, and improve adhesion strong effect

Inactive Publication Date: 2007-03-21

SHANGHAI XINSHENG BUILDING MATERIAL SCI TECH DEV

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

New thermal insulation materials such as expanded perlite, EPS-expanded polystyrene board, XPS-extruded polystyrene board, GS-closed-cell foam glass board, Fine-external wall decoration insulation board, etc. There are a large number of domestic manufacturers producing the aforementioned products, but If these products are to be firmly bonded to the wall, it is also necessary to ensure that these insulation materials can withstand the erosion of the external natural environment. Temperature changes, cold radiation, heat radiation, wind and rain, blowing, etc. will cause damage to the insulation materials, so , it is necessary to have a bonding material with firm bonding, tensile resistance, compression resistance, crack resistance, etc.

[0003] At present, most of them use cement mortar as the bonding material, but the use shows that there are defects in the crack resistance, tensile strength, compression resistance and anti-seepage performance of cement. Due to poor adhesion, in order to enhance the bonding effect, it is necessary to increase the amount of use. , but this will increase the load of the wall and insulation materials, which not only increases the cost and construction troubles, but also the insulation materials are easy to fall off, posing safety hazards, hollowing, water seepage, and cracking will occur after a long time, and the insulation and energy saving requirements cannot be guaranteed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

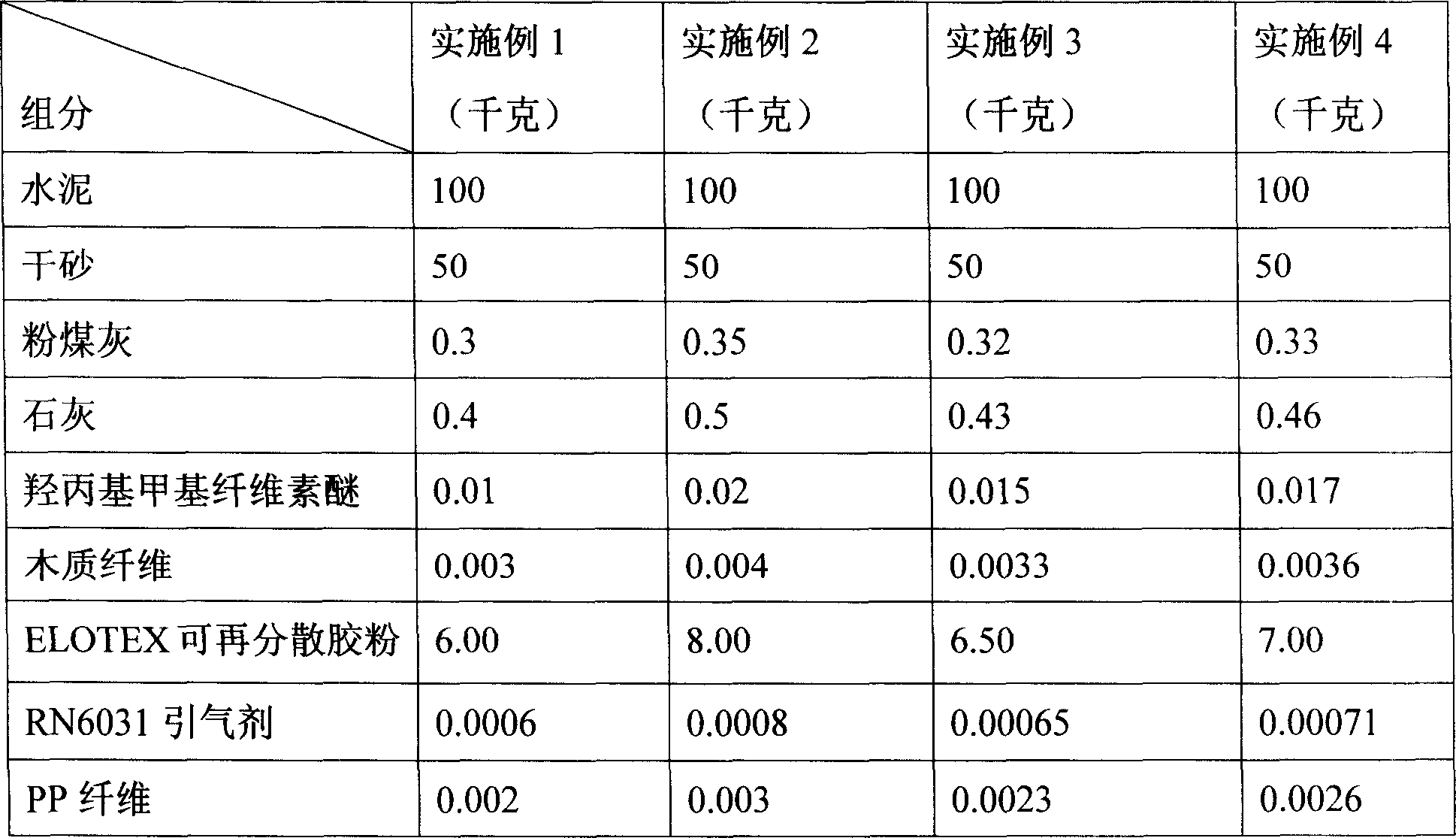

[0046] The components of the present invention are further described below in conjunction with specific examples:

[0047] With the weight parts of cement being 100 calculations, the content of each component by parts by weight proportioning in each embodiment is shown in the table below,

[0048]

[0049] Test items

[0050] detection item

[0051] Test items

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

The wall adhesive powder consists of cement 100 weight portions, dry sand 50 weight portions, fly ash 30-35 weight portions, lime 40-50 weight portions, hydroxypropyl methyl cellulose ether 1-2 weight portions, wood fiber 3-4 weight portions, redispersive gelatin powder 6-8 weight portions, air entraining agent 0.06-0.08 weight portions, and PP fiber 0.2-0.3 weight portions. The wall adhesive powder for building has the advantages of firm adhering, high pressure strength, high tensile strength, excellent antiseepage performance, anticracking, low cost, etc.

Description

technical field [0001] The invention relates to a building material, in particular to a bonding rubber powder for walls. Background technique [0002] At present, the residential area of our country has increased from 40 billion m 2 , Building energy consumption accounts for 30% of the total energy consumption of the society, only a few tenths of percent of old-fashioned residential buildings meet energy-saving standards, and only 15% of new-built residential buildings meet energy-saving standards. With the rapid development of marketization of commercial housing, people's living conditions have been greatly improved. The requirements for housing have developed from the pursuit of area to the pursuit of quality. Designs to improve energy efficiency, improve indoor environment, building facilities and high-performance housing have become the most recent and The focus of future development, in developed countries in Europe and America, wall insulation measures have become a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J1/00C09J101/26

Inventor 杨峻

Owner SHANGHAI XINSHENG BUILDING MATERIAL SCI TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com