Dissolvent hot liquid state phase-change method for synthesizing superhard micro nano material

A micro-nano, solvothermal technology, applied in the process of applying ultra-high pressure, polycrystalline material growth, chemical instruments and methods, etc., can solve the problem that the product is easy to be polluted, the consistency of product performance is deteriorated, and the input-output ratio is high. problems, achieving uniformity and improved isotropy, simplified post-processing, and reduced temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

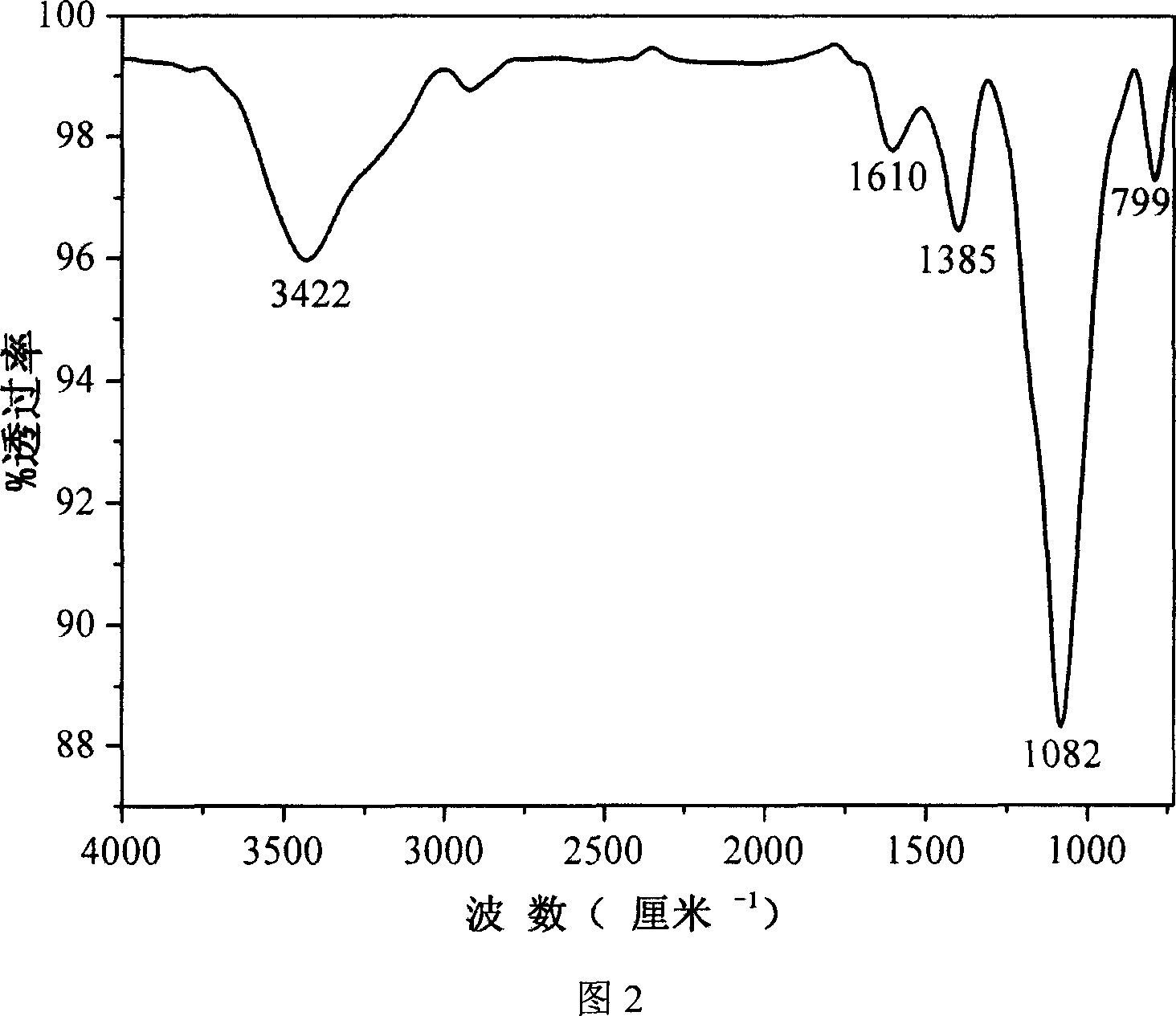

[0043] Embodiment 1: Firstly add metal sodium flakes in the solvent benzene, and distill after standing for 24 hours to remove the water and oxygen contained in the benzene. Under the protection of high-purity nitrogen, weigh an appropriate amount of hexagonal boron nitride nanopowder (average particle size is 8 nanometers) and grind for 15 to 30 minutes, then disperse it in redistilled benzene to obtain a hexagonal boron nitride content of 19.0 grams / L of suspension. After ultrasonic dispersion, the suspension was put into an autoclave, and the autoclave was sealed. Apply a pressure of 80 MPa on the autoclave, and then control the temperature of the autoclave to rise to 280 °C at a rate of 0.87 °C / min. After 4 hours of constant temperature and pressure, the autoclave is naturally cooled to room temperature.

[0044] After the above-mentioned hot pressing process is completed, the solvent is first filtered off, and then the obtained solid product is redispersed in acetone an...

Embodiment 2

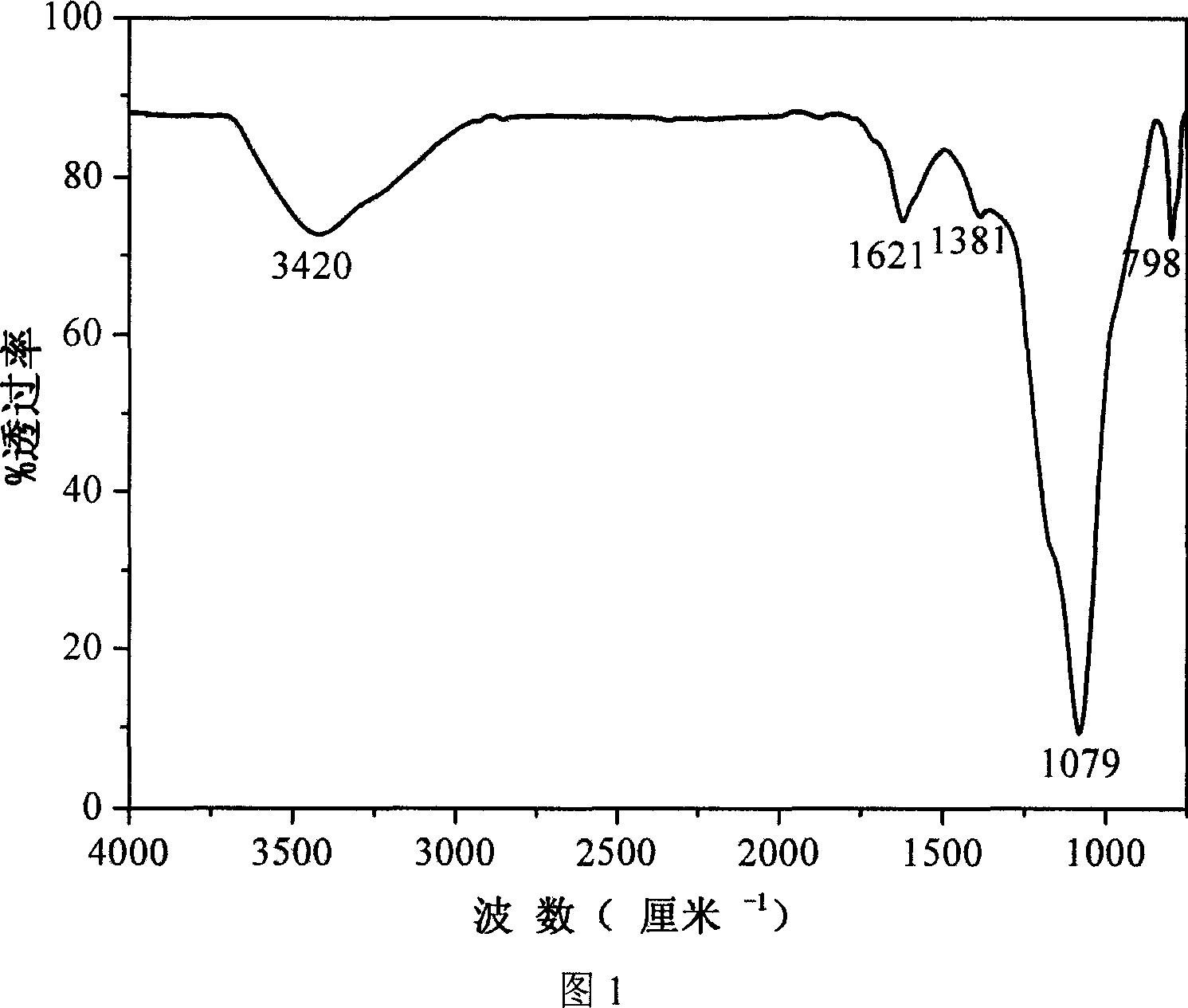

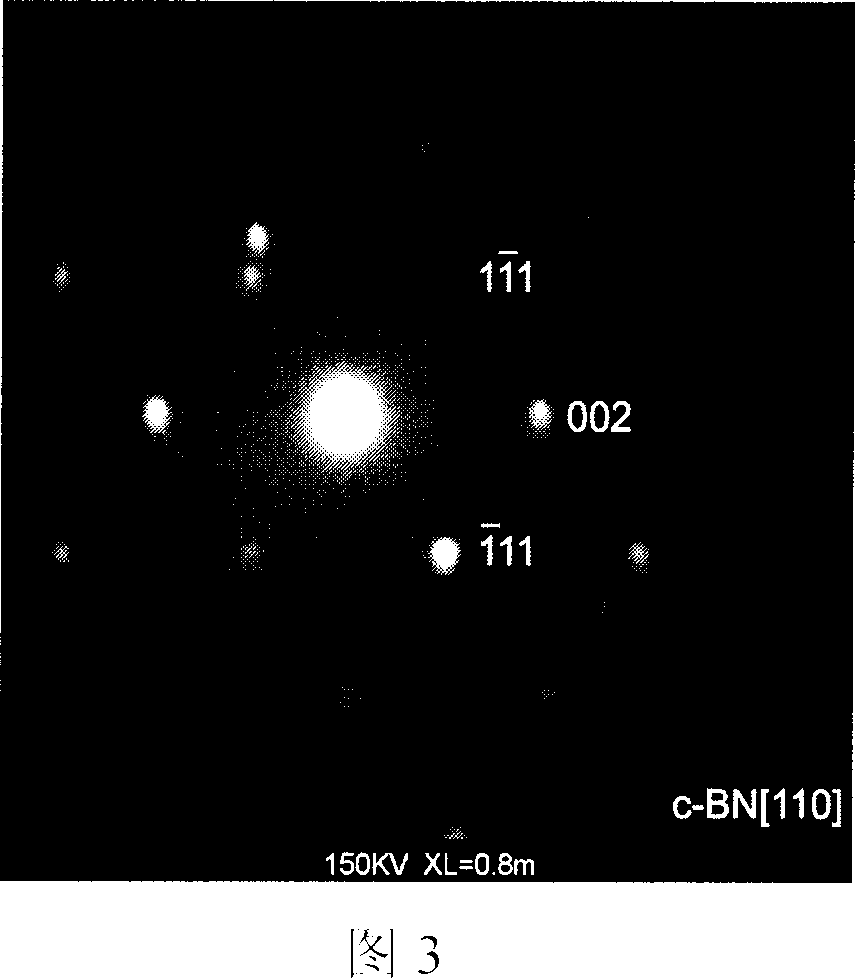

[0045] Example 2: As described in Example 1, the difference is that the hot pressing temperature is 300° C., the heating rate is 0.93° C. / minute, and the hot pressing time is 6 hours. The infrared absorption spectrum of the cubic boron nitride nanocrystal obtained in this way is shown in Figure 1, the selected area electron diffraction diagram is shown in Figure 3, and the transmission electron microscope photo is shown in Figure 5.

Embodiment 3

[0046] Embodiment 3: As described in Embodiment 1, the difference is that the hot pressing temperature is 300° C., the heating rate is 0.93° C. / minute, and the hot pressing pressure is 160 MPa. The selected area electron diffraction pattern of the obtained cubic boron nitride nanocrystal sample is shown in Figure 4, and the microscopic morphology of a single cubic boron nitride grain is shown in Figure 6. The microscopic appearance of the sample is shown in Figure 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com