Thermolysis cream, and prepartion method

A technology of heat dissipation paste and thermal conductivity, which is applied in the field of heat dissipation paste and its preparation, and can solve the problems of affecting heat transfer effect and low thermal impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

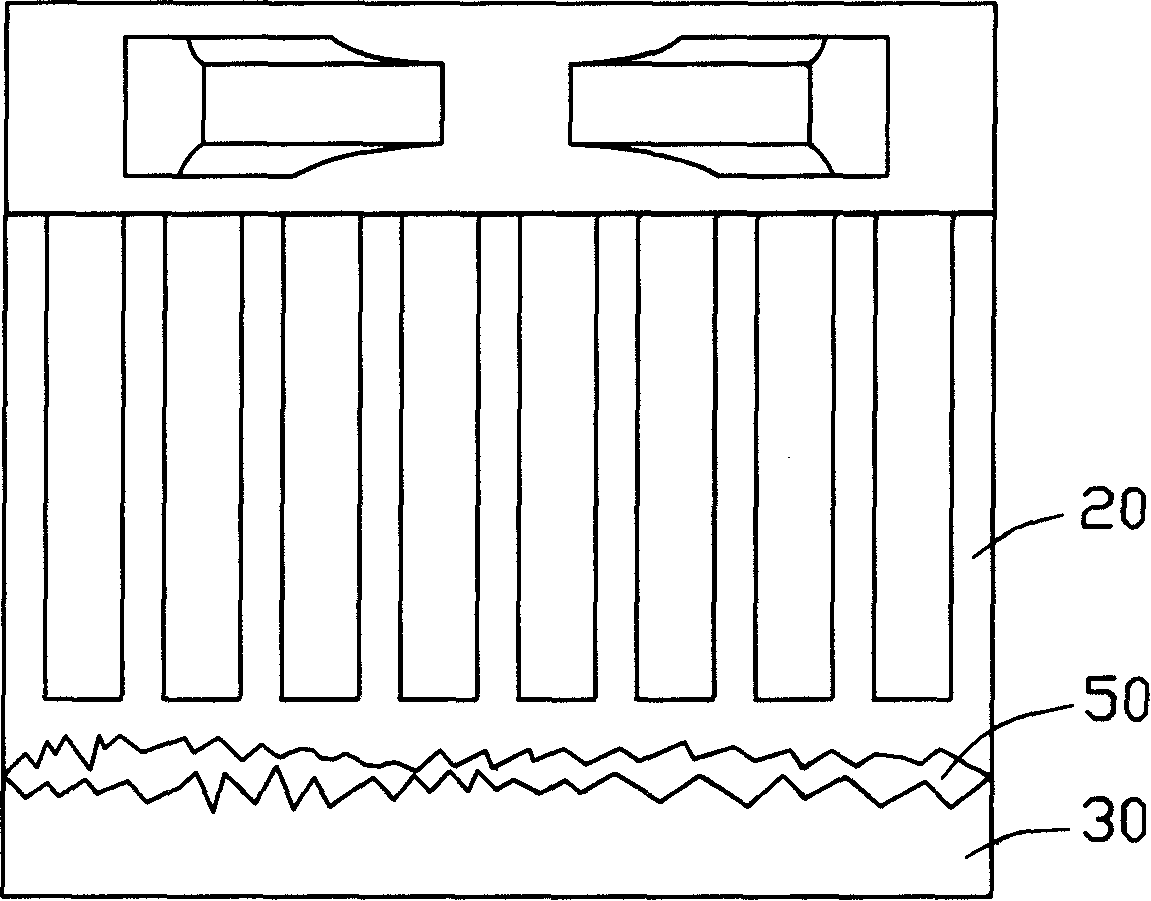

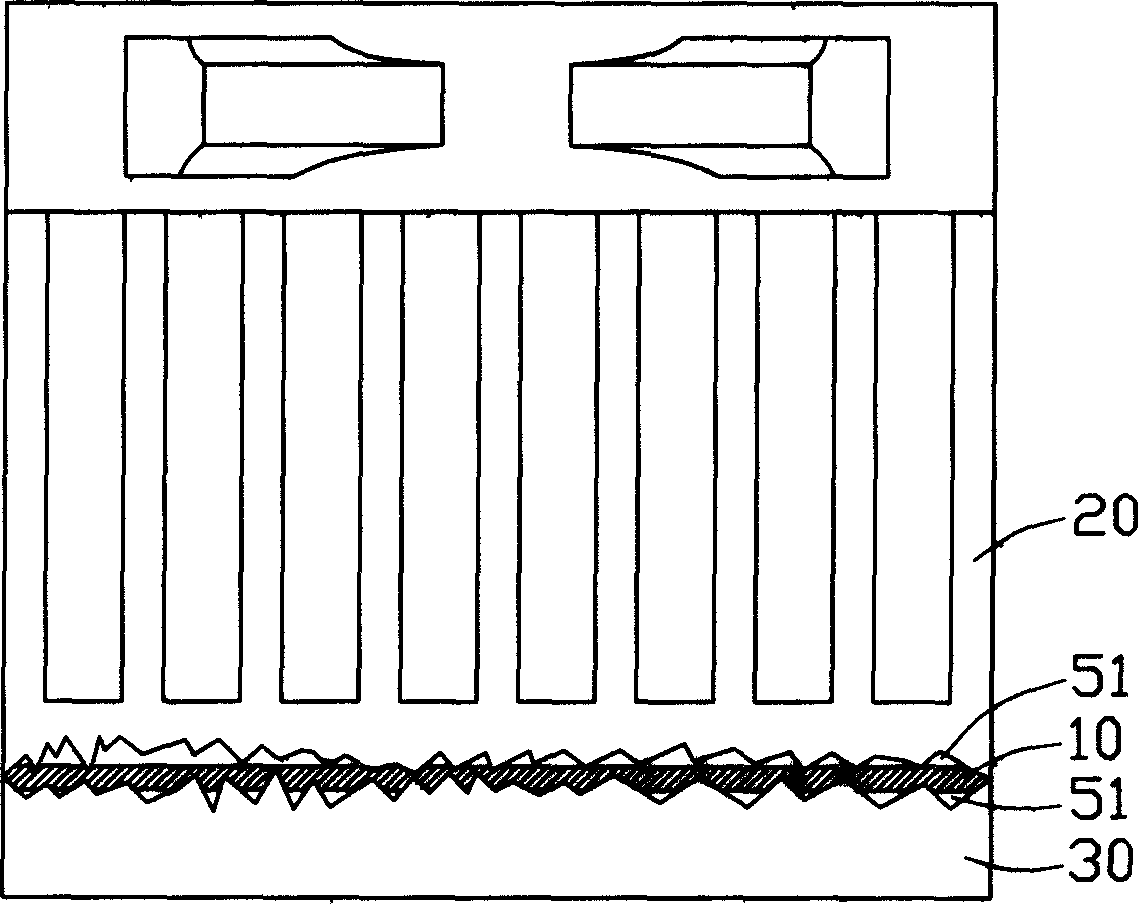

[0022] The thermal paste and its preparation method will be further described in detail below with reference to the accompanying drawings and embodiments.

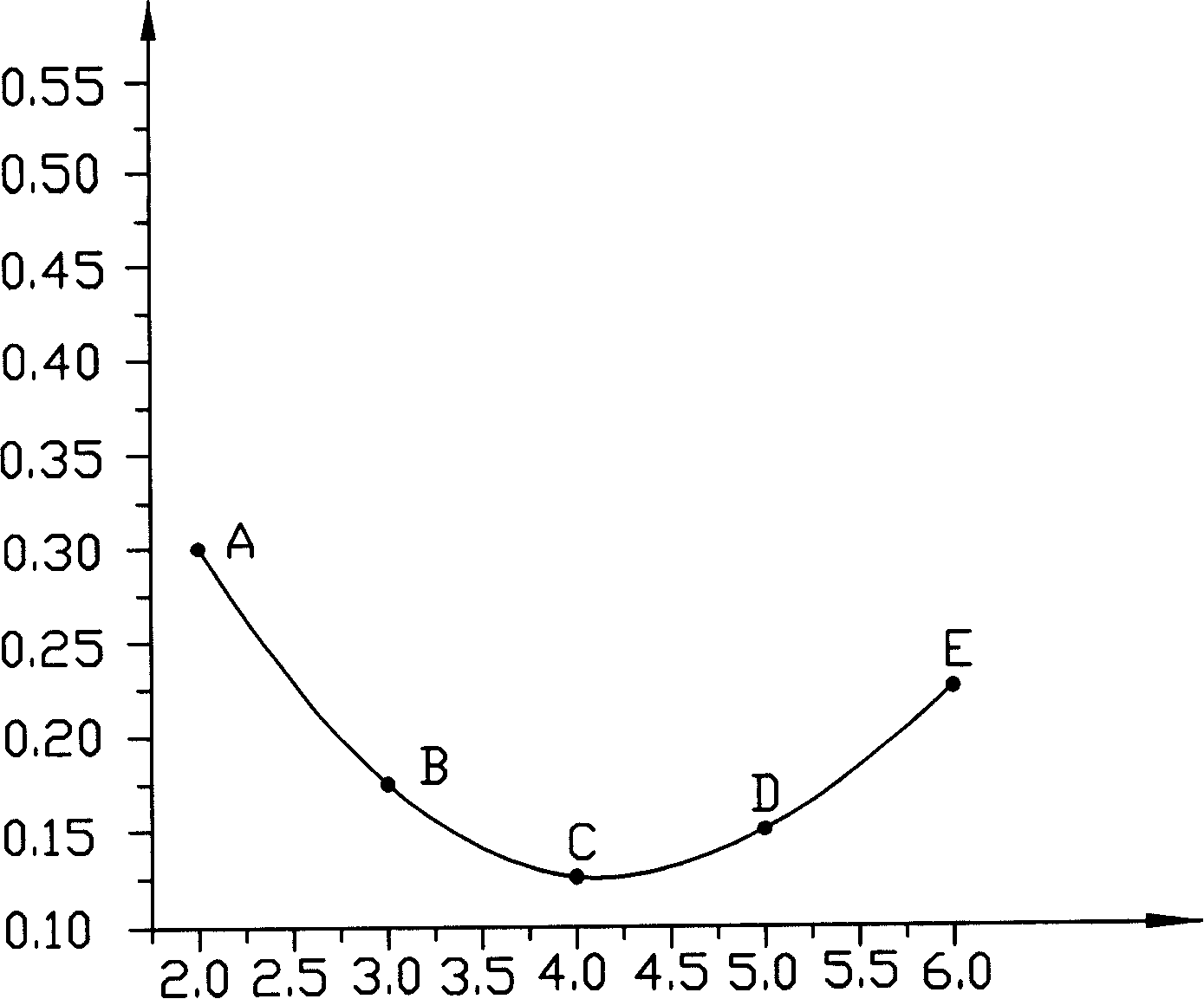

[0023] The thermal paste of this embodiment includes a polymer matrix with a thermal conductivity of 0.1-0.2W / mK (W / m·K) and a thermally conductive filler with a thermal conductivity of 20-1000W / mK. The thermally conductive filler and the polymer matrix The mass ratio is 3:1~7:1.

[0024] The optimal mass ratio of the above-mentioned thermally conductive filler to the polymer matrix is 4:1, and the resulting heat dissipation paste has the best heat dissipation effect and the minimum thermal resistance. The polymer matrix is a polyhydroxy ester substance. The particle size of the thermally conductive filler is less than 1 μm, preferably 0.5-1 μm. The thermally conductive filler includes zinc oxide powder, aluminum nitride powder, silicon carbide powder and the like.

[0025] The preparation method of the thermal past...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com