Method for preparing Nano carbon white from fly ash based on gas phase sol gel method

A sol-gel method, nano-silica technology, used in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Such as figure 1 , grind the fly ash sample with a mortar, soak it in 4mol / L nitric acid, stir it continuously for 2 hours with an electric mixer, filter it with suction, wash it, and dry it in a vacuum oven for 8 hours, and put it in a muffler furnace at a high temperature of 800°C Burn for 4 hours to remove residual combustible substances such as charcoal. The burnt fly ash was put into 4mol / L nitric acid solution and stirred with an electric mixer for 1 hour to remove impurities such as iron and aluminum, and obtained silica by washing, suction filtration and vacuum drying. Put 3g of sodium fluoride and 5g of silicon dioxide into a four-neck flask, add concentrated sulfuric acid dropwise, the rate of concentrated sulfuric acid is controlled at 40 drops / min, the gas generated is passed into concentrated sulfuric acid to dry, and the temperature of the oil bath is controlled at 140°C , the gas is then fed into a 4.5g / L sodium dodecyl sulfate (SDS) solution for hydroly...

example 2

[0021] Such as figure 2 , Obtain the silicon dioxide needed for the experiment in the same way as example 1. Put 5g of sodium fluoride and 15g of silicon dioxide into a four-necked flask, add concentrated sulfuric acid dropwise, the rate of concentrated sulfuric acid is controlled at 30 drops / min, the gas generated is passed into concentrated sulfuric acid for drying, and the temperature of the oil bath is controlled at 100°C , the gas is then passed into a 5.5g / L sodium lauryl sulfate solution for hydrolysis, the pH of the solution is kept at 6.3, a sol is formed, the aeration is stopped, the sol is placed in a beaker, sealed, and gelled in a 60°C water bath. Wash the gel with distilled water until the conductivity of the filtrate is less than 50 μs / cm, dry in an oven at 80°C, and burn in a muffle furnace at 350°C to obtain nano-silica. Its specific surface area is 151.27 / m 2 g -1 .

example 3

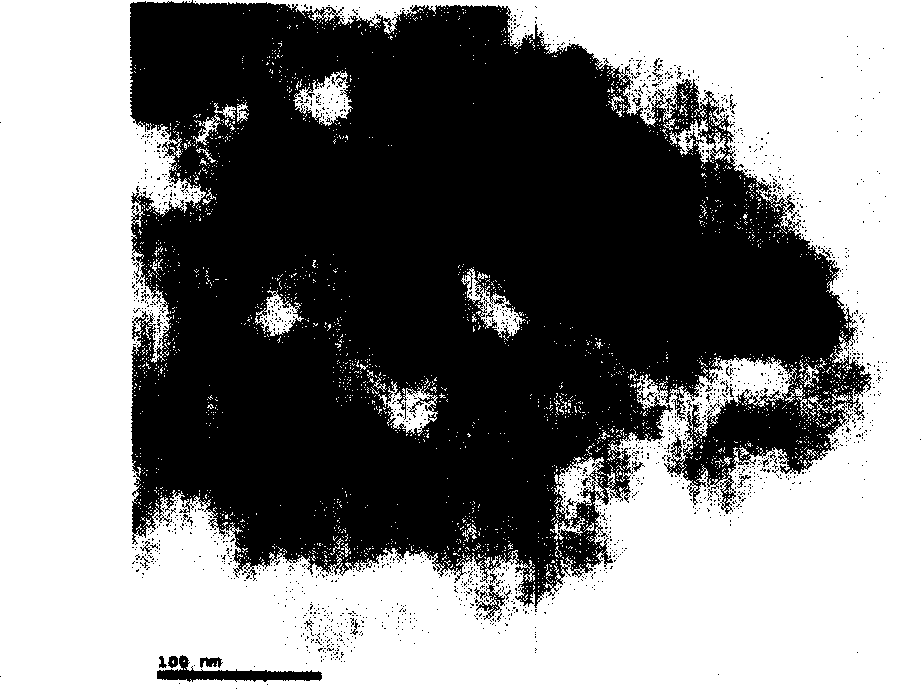

[0023] Such as image 3 , Obtain the silicon dioxide needed for the experiment in the same way as example 1. Put 8g of sodium fluoride and 25g of silicon dioxide into a four-neck flask, add concentrated sulfuric acid dropwise, the rate of adding concentrated sulfuric acid is controlled at 10 drops / min, the generated gas is passed into concentrated sulfuric acid for drying, and the temperature of the oil bath is controlled at 180°C , the gas is passed into a 2.5g / L sodium dodecyl sulfate solution for hydrolysis, the pH of the solution is kept at 1.85, a sol is formed, the ventilation is stopped, the sol is placed in a beaker, sealed, and gelled in a water bath at 25°C. Wash the gel with distilled water until the conductivity of the filtrate is less than 50 μs / cm, dry it in an oven at 100°C, and burn it in a muffle furnace at 450°C to obtain nano-silica. Its specific surface area is 631.78 / m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com