Casting method for exhaust branch pipe of thin-wall ball iron triplet

A technology of exhaust branch pipe and ductile iron, which is applied in casting molding equipment, casting mold, casting mold composition, etc., to achieve the effect of improving dimensional accuracy, preventing blisters, and improving mold filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific examples, but the protection scope of the present invention should not be limited thereby.

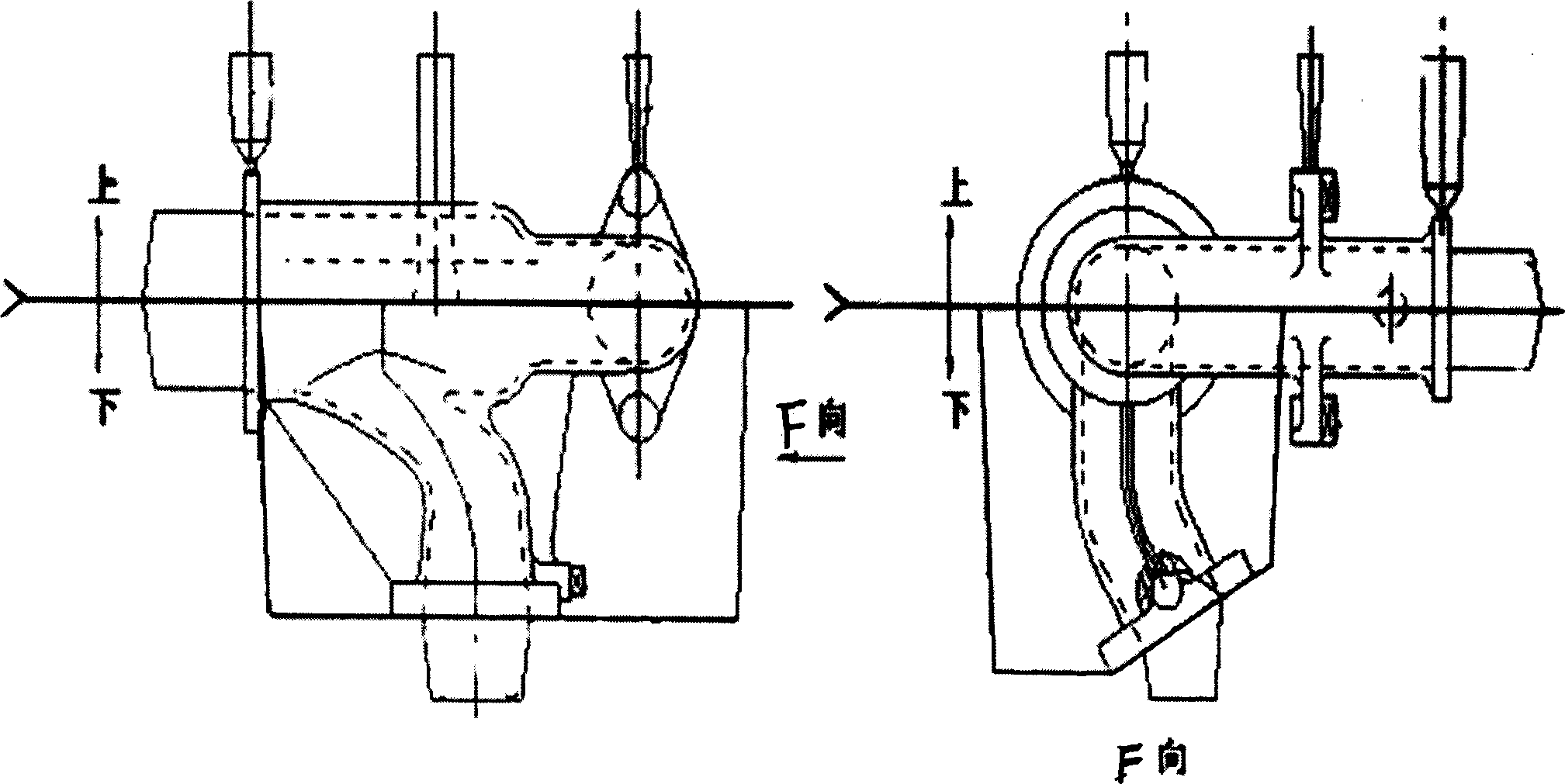

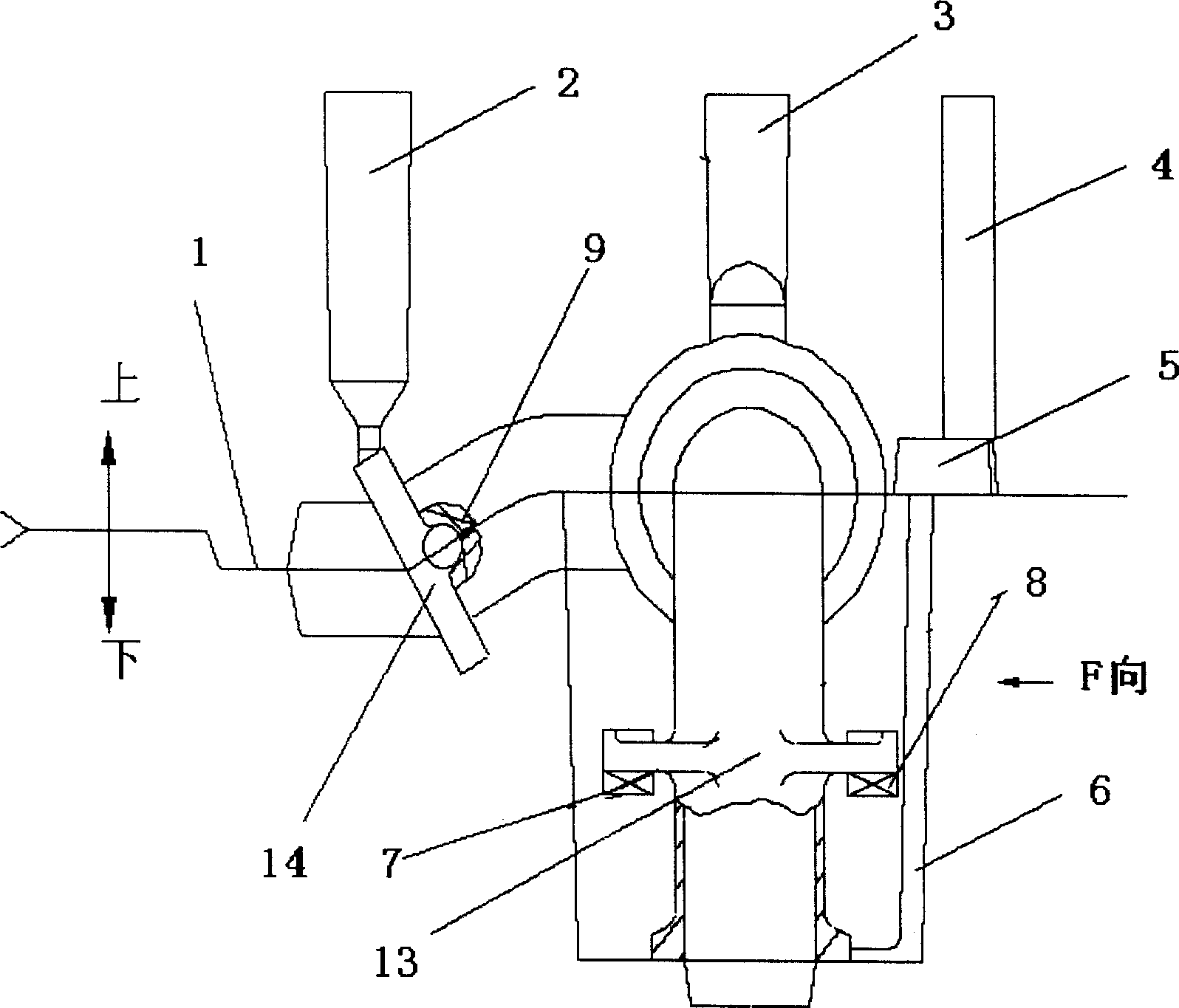

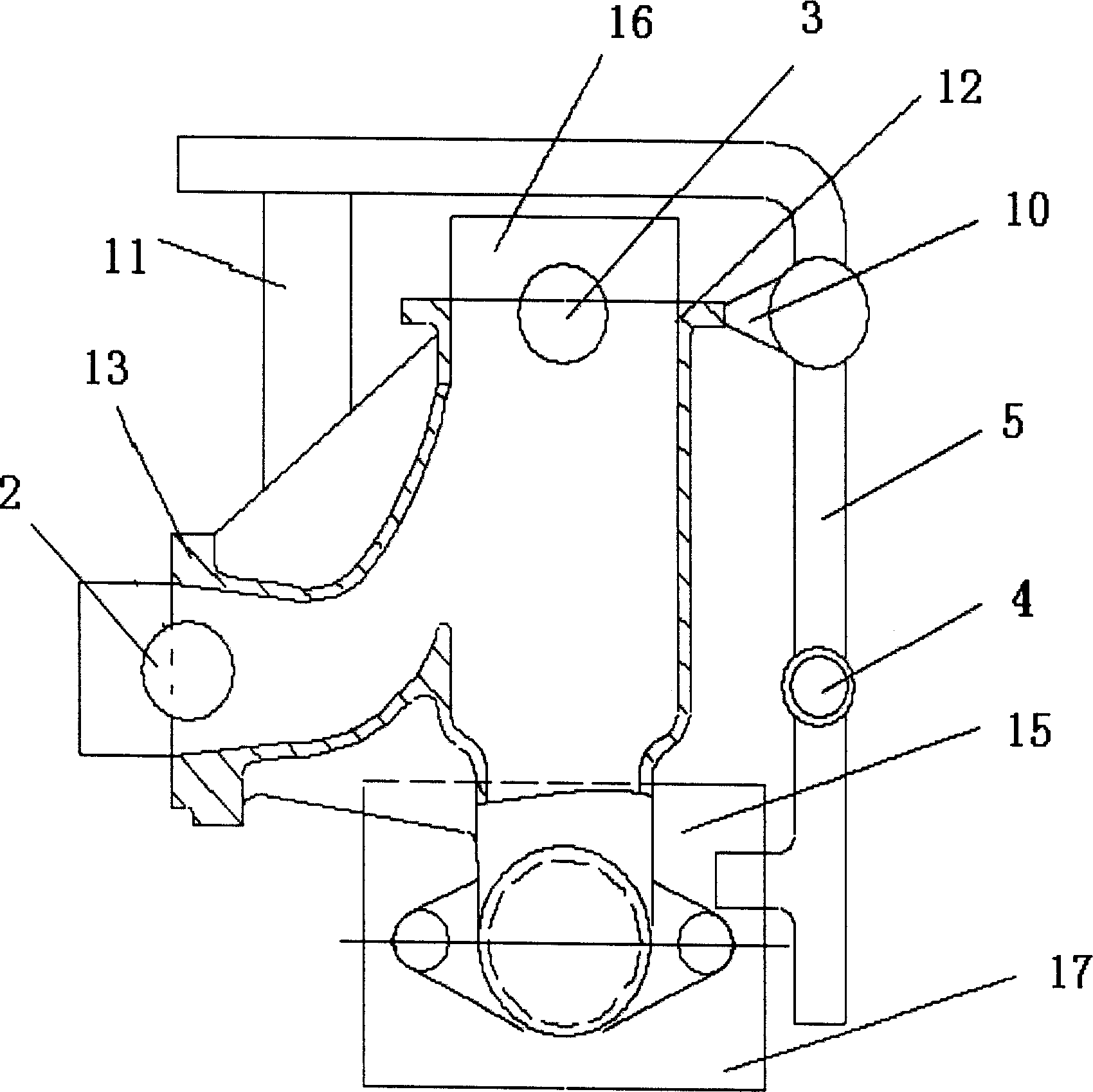

[0044] see figure 2 , image 3 and Figure 4 , figure 2 The front view of the curved surface parting in the casting method of the three-way exhaust branch pipe of the present invention, image 3 The top view of the curved surface parting in the casting method of the three-way exhaust branch pipe of the present invention, Figure 4The F-direction view of the curved surface parting in the casting method of the three-way exhaust branch pipe of the present invention. The curved surface formed by the center line of C exhaust branch pipe 14 with three bending angles and the center line of A exhaust branch pipe 12 is the curved surface parting surface 1 of the upper and lower sand boxes, so that the C row with three bending angles The air branch pipe 14 and the A exhaust branch pipe 12 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com