Special-shaped wall integral anchor rod

An integrated, anchor injection technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of pipe wall thickness thinning, poor sealing, easy to rust, etc., to achieve enhanced tensile strength and tightness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

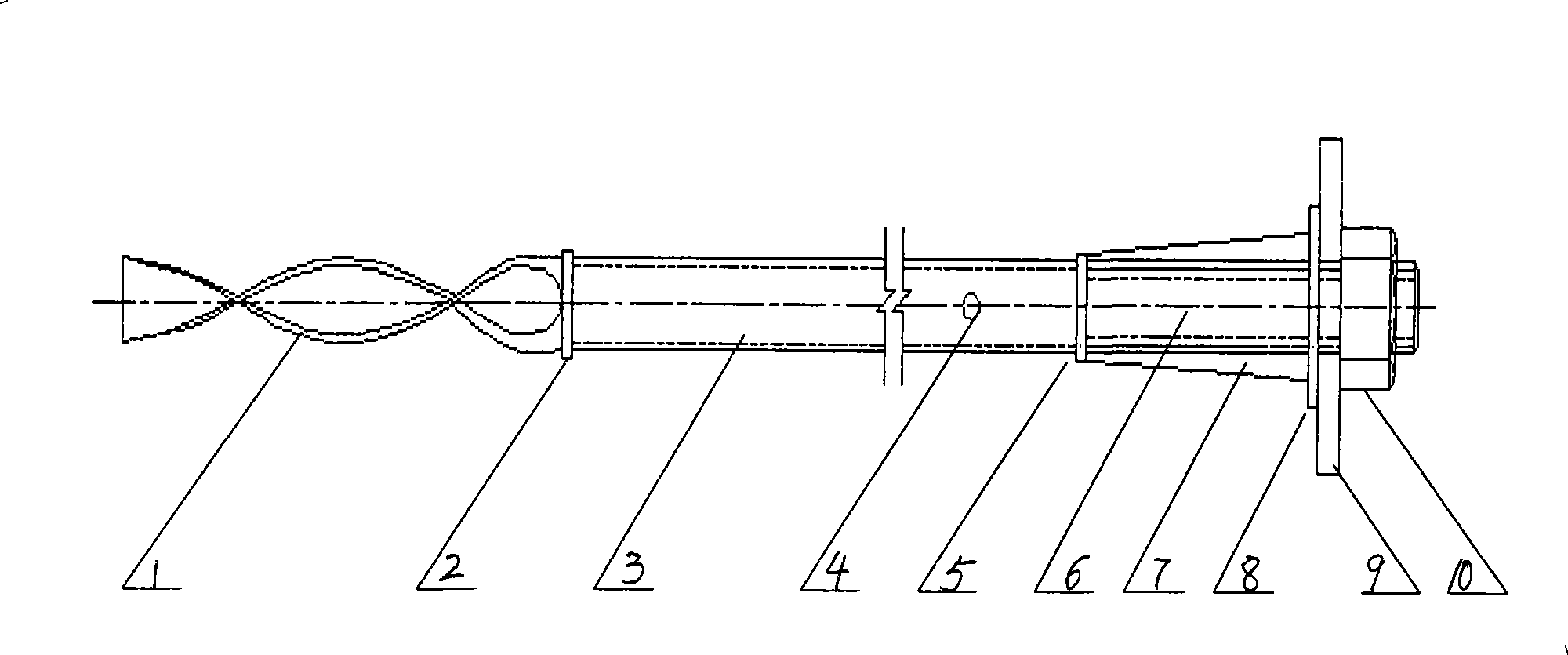

[0018] The implementation of the present invention will be further described below according to the accompanying drawings.

[0019] It includes a steel pipe body 3 whose length is compatible with the grouting depth. The tail of the steel pipe body 3 is connected to the exposed section 6 to form a different-walled steel pipe. Grouting holes 4 with a diameter of 6 mm are drilled at intervals of 120 mm in the axial direction of the steel pipe body 3 . The front end of the body 3 is processed into a twist shape to become the anchor end 1, and at the same time, a retaining ring 2 is processed at the initial part of the anchor end 1 to prevent the coagulant from flowing out when stirring. Threads are processed on the exposed section 6, and the diameter-reducing part forms a convex ring 5 during butt joint processing.

[0020] When installing the anchor rod, cover the synthetic rubber grout stopper 7, the compression washer 8 and the tray 9 from the orifice, and tighten the nut 10 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com