End supporting apparatus for controlling backstay cable

A technology of supporting device and cable, applied in the direction of linear motion axis, etc., can solve problems such as poor operation feeling, and achieve the effect of improving operation feeling, ensuring vibration absorption, and slowing the surge of spring characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, one embodiment of the present invention will be described based on the drawings.

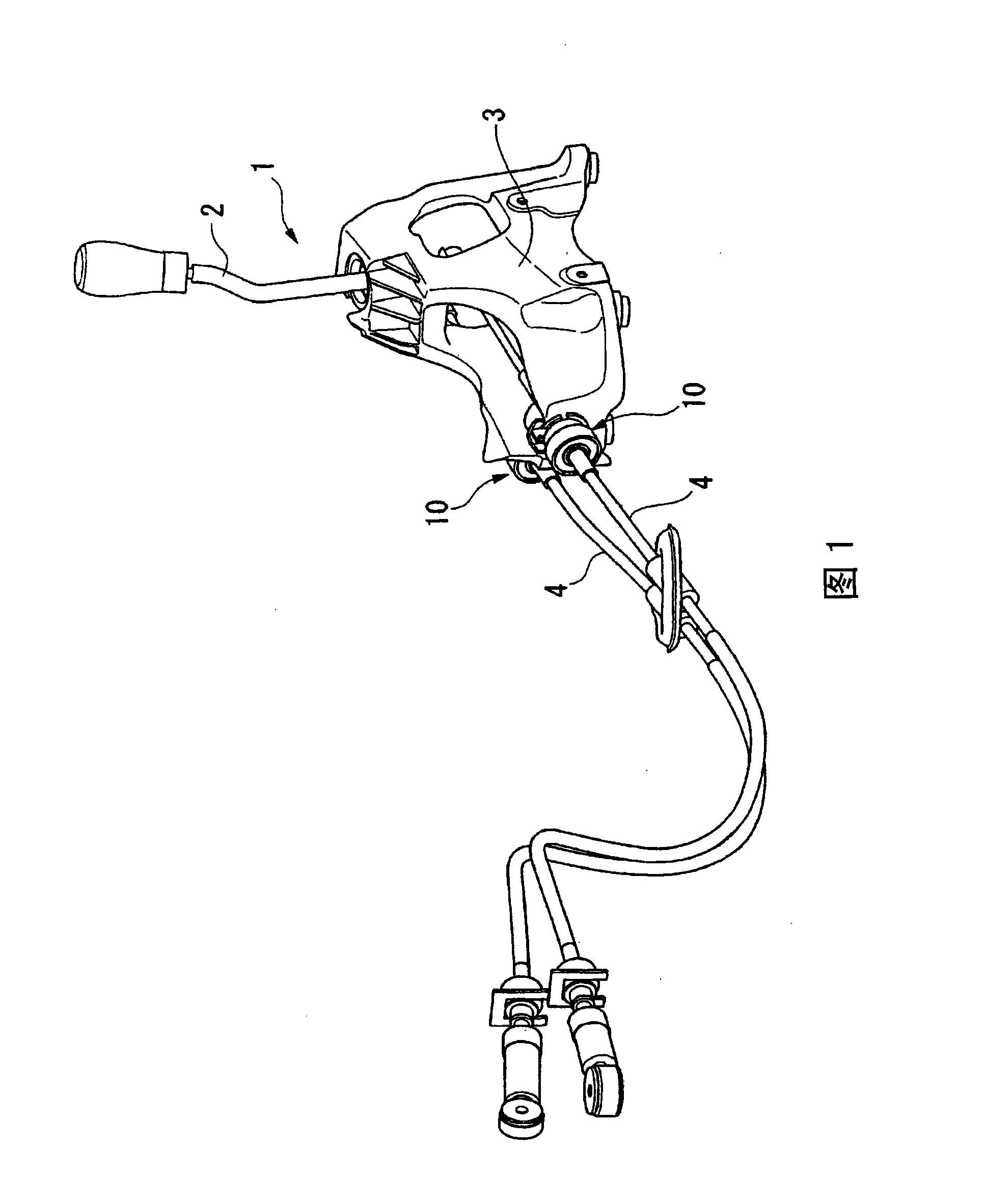

[0034] figure 1 It is a perspective view showing the operation system on the shift lever 2 side of the shift device 1 to which the end support device 10 of the present invention is applied.

[0035] As shown in the figure, the ends of the two control cables 4 are supported by the end support device 10 on the vehicle body side lever support portion 3 holding the shift lever 2 (fixed portion on the vehicle body side). One end side of each control cable 4 is connected to the shift lever 2 side, and the other end side is connected to the main body portion (transmission) side of the transmission device 1 .

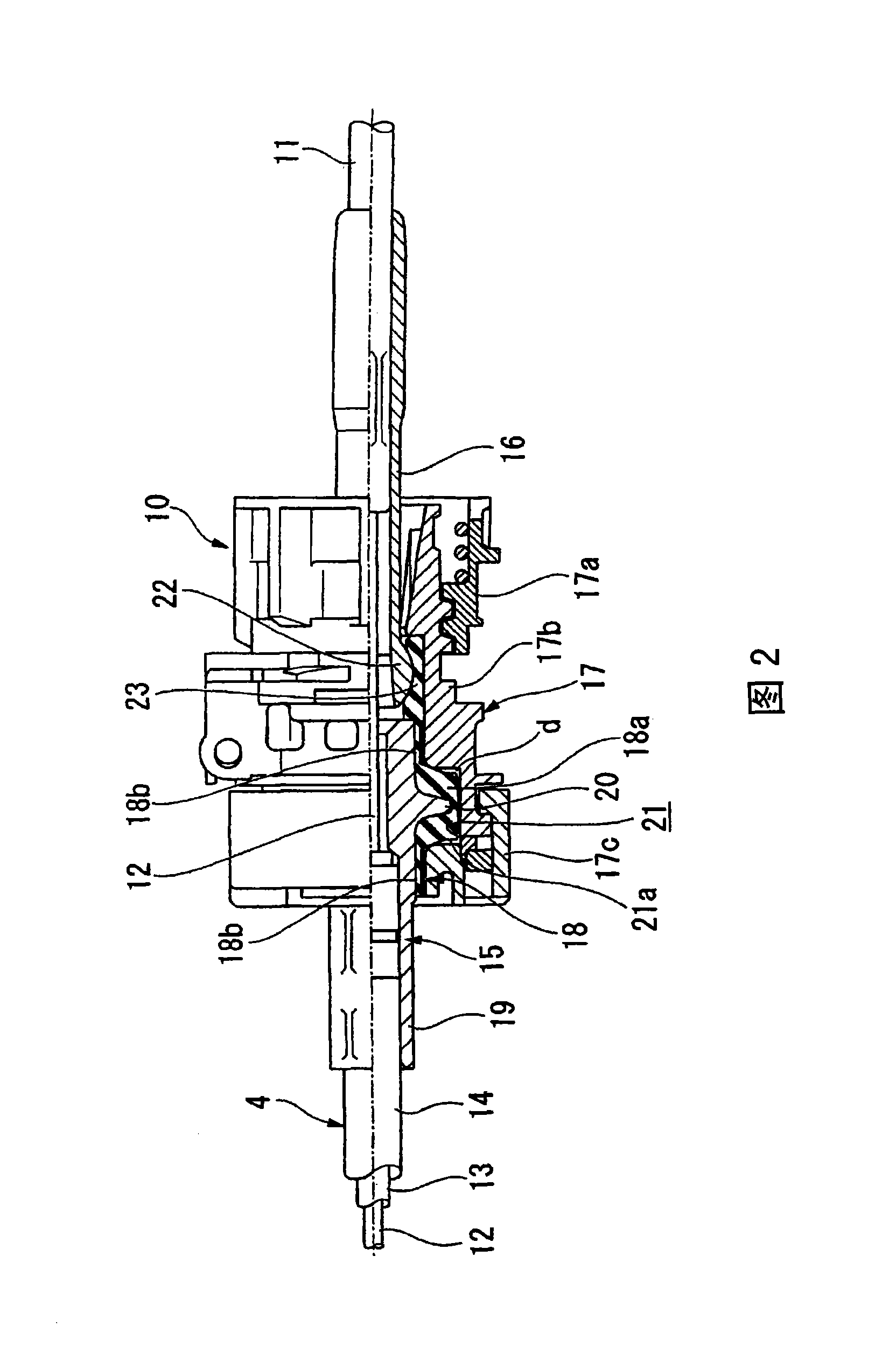

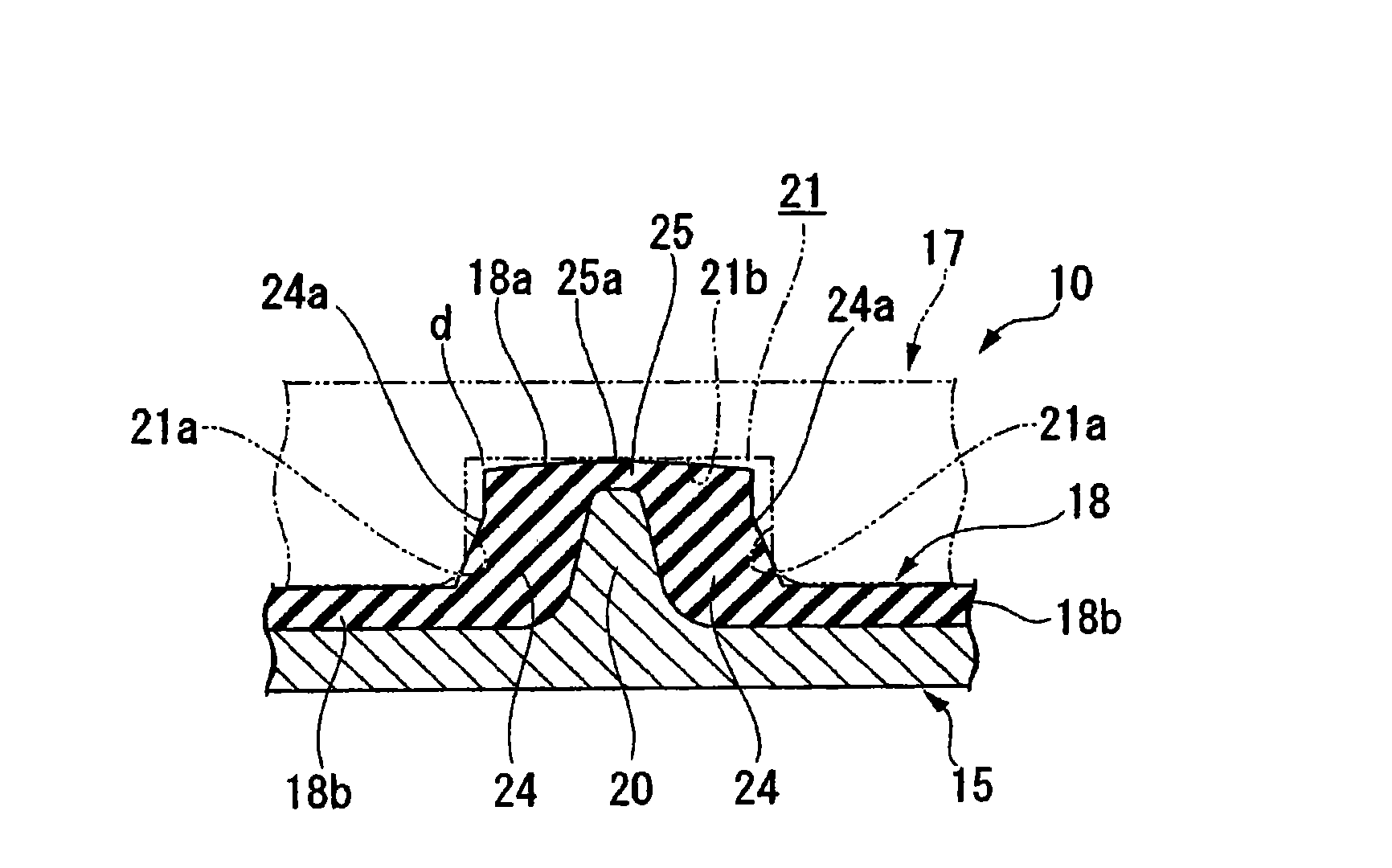

[0036] figure 2 It is a cutaway side view of the lower half of the end support device 10 .

[0037] The control cable 4 is composed of an internal cable 12 whose both ends are directly connected to a lever 11 on the shift lever 2 side and a lever (not shown) on the main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com