Spinning method for bottle neck part of electrically conductive contact finger and matched spinning device

A technology of conductive contact finger and processing device, which is applied in the field of spinning processing, can solve the problems of reducing the processing cost of the conductive contact finger, cannot guarantee the wall thickness of the bottle neck of the conductive contact finger, etc., and achieves good flow capacity, convenient implementation, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

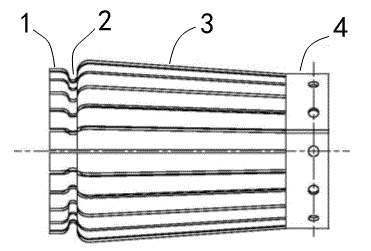

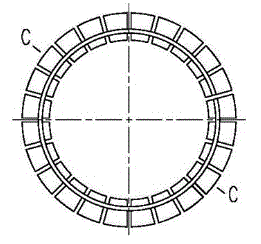

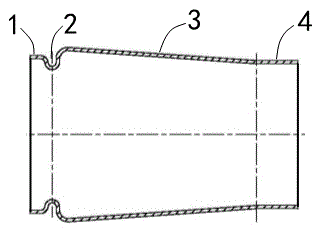

[0026] The conductive contact finger spinning processing method of the present invention is mainly to use the spinning wheel and the mandrel to form the bottleneck structure of the conductive contact finger, and at the same time, apply the conductive contact finger cylindrical blank along the axial direction of the mandrel. Axial pressure, thereby changing the material flow direction, ensures that the thinnest part of the conductive contact finger bottle neck is greater than 3 mm. In order to realize the spinning processing method, the present invention provides a spinning processing device dedicated to implementing the spinning processing method. The specific embodiment of the spinning processing device is as follows: Figure 4 to Figure 13 As shown, the processing device has a core mold for supporting and cooperating with the inner wall surface of the conductive contact finger cylindrical blank 60. and a mold core for supporting between the outer peripheral surface of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com