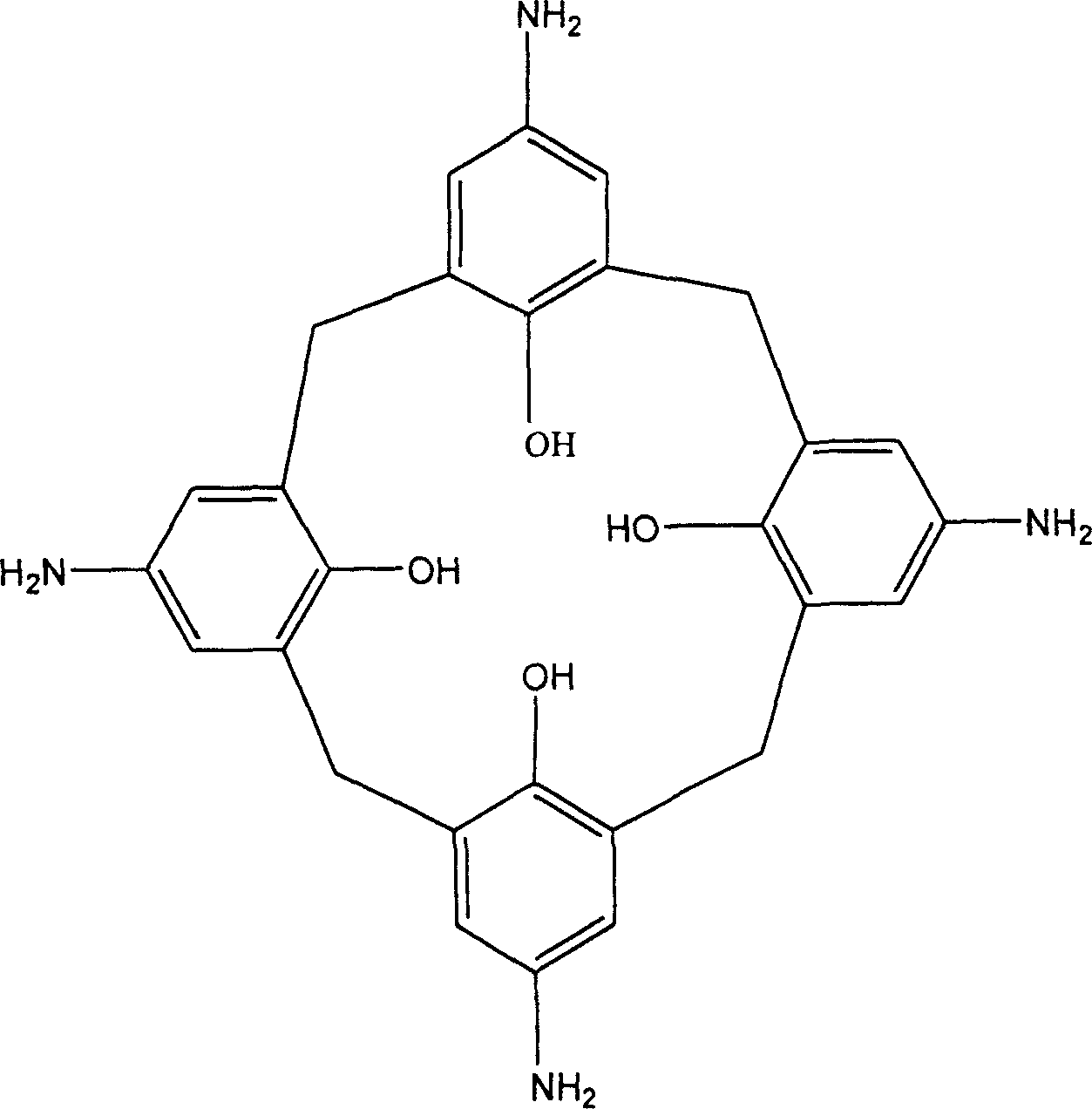

Multi oxometallate and amination calixarene self assembled organic-inorganic composite film

A technology for amide calixarene and polyoxometalate, which is used in organic chemistry, metal material coating technology, technology for producing decorative surface effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: (BW 12 / pAC4) n Preparation of multilayer organic-inorganic thin films

[0010] First, clean the quartz sheet: put the quartz glass sheet in 98% H 2 SO 4 with 30%H 2 o 2 (7:3v / v) dipping treatment at 80°C for 40min, take it out and wash it with distilled water; then immerse in H 2 O:H 2 o 2 : NH 3 =5:1:1 (v / v / v) dipping treatment at 80°C for 20 minutes, take it out, wash it with distilled water, and dry it with nitrogen to obtain a film-forming substrate for use.

[0011] Then perform PEI cationization on the substrate: immerse the substrate after the above-mentioned treatment procedure in 10 mg / mL polyethyleneimine PEI solution for 20 minutes, take it out, wash it with distilled water, and dry it with nitrogen.

[0012] Then the PEI cationized substrates were alternately immersed in 4.0×10 -2 M's BW 12 solution and 2.0 x 10 -3 In the MpAC4 solution (through hydrochloric acid cationization), place respectively 20min, wash with distilled water a...

Embodiment 2

[0014] Embodiment 2: ([Co 4 II (H 2 O) 2 (PW 9 o 34 ) 2 ] 10- / pAC4) n Preparation of multilayer organic-inorganic thin films

[0015] Synthesis steps and testing steps refer to Example 1. The immersion solution of PEI cationized substrate adopts 5.0×10 -3 M's [Co 4 II (H 2 O) 2 (PW 9 o 34 ) 2 ] 10- solution.

[0016] The UV-Vis spectrum shows that the prepared film is at the wavelength of 250nm and 300nm [Co 4 II (H 2 O) 2 (PW 9 o 34 ) 2 ] 10- The absorbance of / pAC4 increases linearly with the increase of the number of layers, indicating that the prepared film has good uniform growth.

Embodiment 3

[0017] Embodiment 3: (BW 12 / pAC4) n Characterization of Electrochemical Behavior of Multilayer Organic-Inorganic Thin Films

[0018] The electrochemical behavior was carried out using an Epsilon type electrochemical workstation produced by BAS Company of the United States. A glassy carbon electrode (3mm) was used as the working electrode, a platinum wire electrode was used as the counter electrode, and Ag / AgCl / KCl (3M) was used as the reference electrode. The supporting electrolyte is 0.1M NaCl solution. The electrochemical method was cyclic voltammetry.

[0019] The working electrode modification steps are as follows: first, the glassy carbon electrode (3 mm in diameter) was pretreated with 1.0, 0.3 and 0.05 μm α-Al 2 o 3 The polishing powder is polished separately, cleaned with acetone and distilled water ultrasonically after each polishing, and finally dried with nitrogen; then immersed in 10mg / mL polyethyleneimine PEI solution for 20min, washed with distilled water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com