Self-assembly preparation of organic/inorganic compound film by transient metal substitution of polyoxometallate and polyamide-amine

A polyoxometalate, transition metal technology, applied in the field of organic-inorganic composite thin film preparation, achieves the effects of high stability, simple operation, and short film-forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

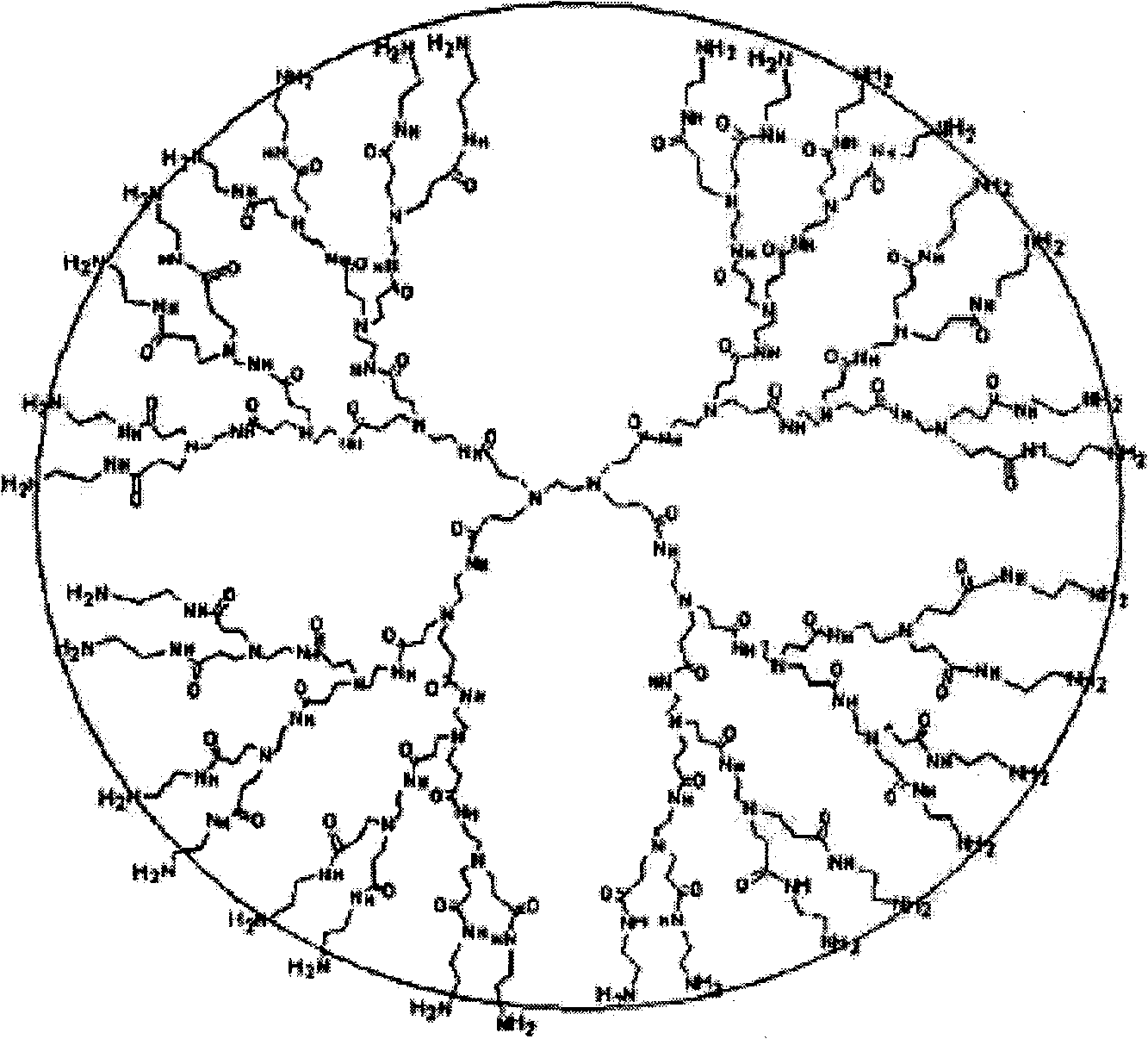

Image

Examples

Embodiment 1

[0020] 1. Cleaning:

[0021] Sonically clean the conductive glass substrate in acetone solution for 5 minutes, take it out and rinse it with distilled water, immerse it in NaOH solution and ultrasonically clean it for 5 minutes, take it out and rinse it with distilled water, and dry it with nitrogen gas to get the cleaned conductive glass substrate for use.

[0022] 2. Cationization:

[0023] The cleaned conductive glass substrate was immersed in 1% (wt%, mass fraction) PDDA solution for 30 minutes, rinsed with deionized water, and dried with nitrogen to obtain a cationized conductive glass substrate.

[0024] 3. Film self-assembly:

[0025] Put the cationized conductive glass substrate in 5mmol·L -1 PMo 11 In the solution of Cu, within the potential range of -0.1 ~ 0.65V, at 100mV s -1 The scanning speed was scanned for 25 weeks, and then washed with ethanol solution and deionized water and placed in 1% (wt%) PAMAM solution at 100mV·s -1 The speed scan scans for 25 weeks...

Embodiment 2

[0029] 1. Cleaning:

[0030] The glassy carbon electrode substrates were sequentially coated with 1.0, 0.3 and 0.05 μm α-Al 2 o 3 Powder polishing, ultrasonic cleaning in ethanol solution and distilled water for 10min, at 0.5mol L -1 h 2 SO 4 Control the potential range of -0.1 to 0.65V in the solution for cyclic potential scanning until a stable standard cyclic voltammogram is obtained.

[0031] 2. Cationization:

[0032] Place the cleaned glassy carbon electrode substrate in 5mmol·L -1 Soak in the ethanol solution of p-aminothiophenol for 15 hours, take it out, wash it with distilled water, and dry it with nitrogen to obtain a cationized glassy carbon electrode substrate.

[0033] 3. Film self-assembly:

[0034] Put the cationized glassy carbon electrode substrate in 5mmol·L -1 PMo 11 In the solution of Cu, in the range of potential -0.1 ~ 0.65V at 100mV s -1 The scanning speed was scanned for 25 weeks, washed with ethanol solution and deionized water, and then pla...

Embodiment 3

[0037]The specific preparation method is with reference to the preparation process of the multilayer composite thin film in embodiment 1, and the X-ray photoelectron spectrum of thin film and atomic force microscope characterization result show that this method has successfully prepared PMo 11 Compared with the traditional immersion method, the Cu / PAMAM multilayer composite film has a simple preparation process, a short time, and better uniformity of the prepared film.

[0038] The cyclic voltammetric behavior test result of different layers thin films shows that the PMo prepared by the method in embodiment 2 11 Compared with the traditional immersion method, the Cu / PAMAM composite film has better uniformity, higher order and better reproducibility.

[0039] With reference to the composite film prepared by the method of Example 1 and Example 2, in the potential range of -0.1-0.65V, 0.5mol L -1 H 2 SO 4 , at a scan rate of 0.1V·s -1 After 50 scans, only 2.7% of the peak cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com