Process for high performance treatment of organic sewage and reduction of excess sludge output

A technology for excess sludge and organic wastewater, which is applied in the field of biological technology to treat sewage, can solve the problems of insignificant sludge reduction effect, alarming dosage, environmental safety and other problems, so as to reduce the cost of sewage treatment and sludge treatment and disposal. , Improve the effect of sewage purification and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

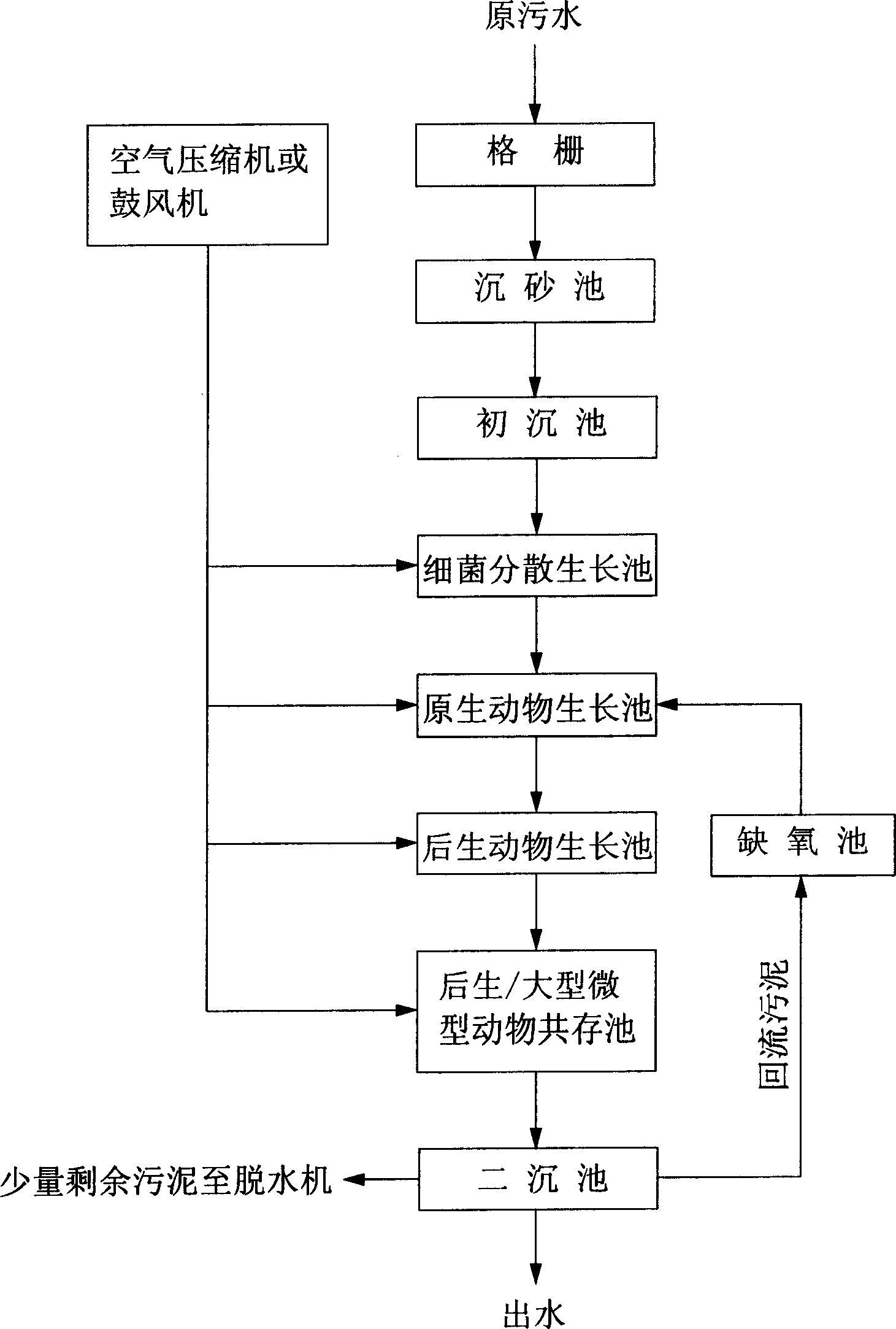

[0015] Specific implementation mode one: combine figure 1 , this embodiment uses biological predation to reduce the amount of excess sludge according to the following method:

[0016] 1. First, the raw sewage is lifted to a certain height by the lifting pump station to meet the water head required for the subsequent section to rely on gravity flow.

[0017] 2. Grille: It is used to intercept large suspended or floating objects, such as plastic products, fiber scraps, hair, wood chips, fruit peels, vegetables, etc., so as to reduce the load of subsequent processing structures and make them operate normally.

[0018] 3. Grit chamber: remove the dense sand and gravel particles in the sewage, such as silt, cinder, etc., to reduce the load of the primary sedimentation tank and improve the treatment conditions of the sludge treatment structure. The grit chamber can aerate the grit chamber Preliminary removal of organic matter attached to the particles.

[0019] 4. Primary sediment...

specific Embodiment approach 2

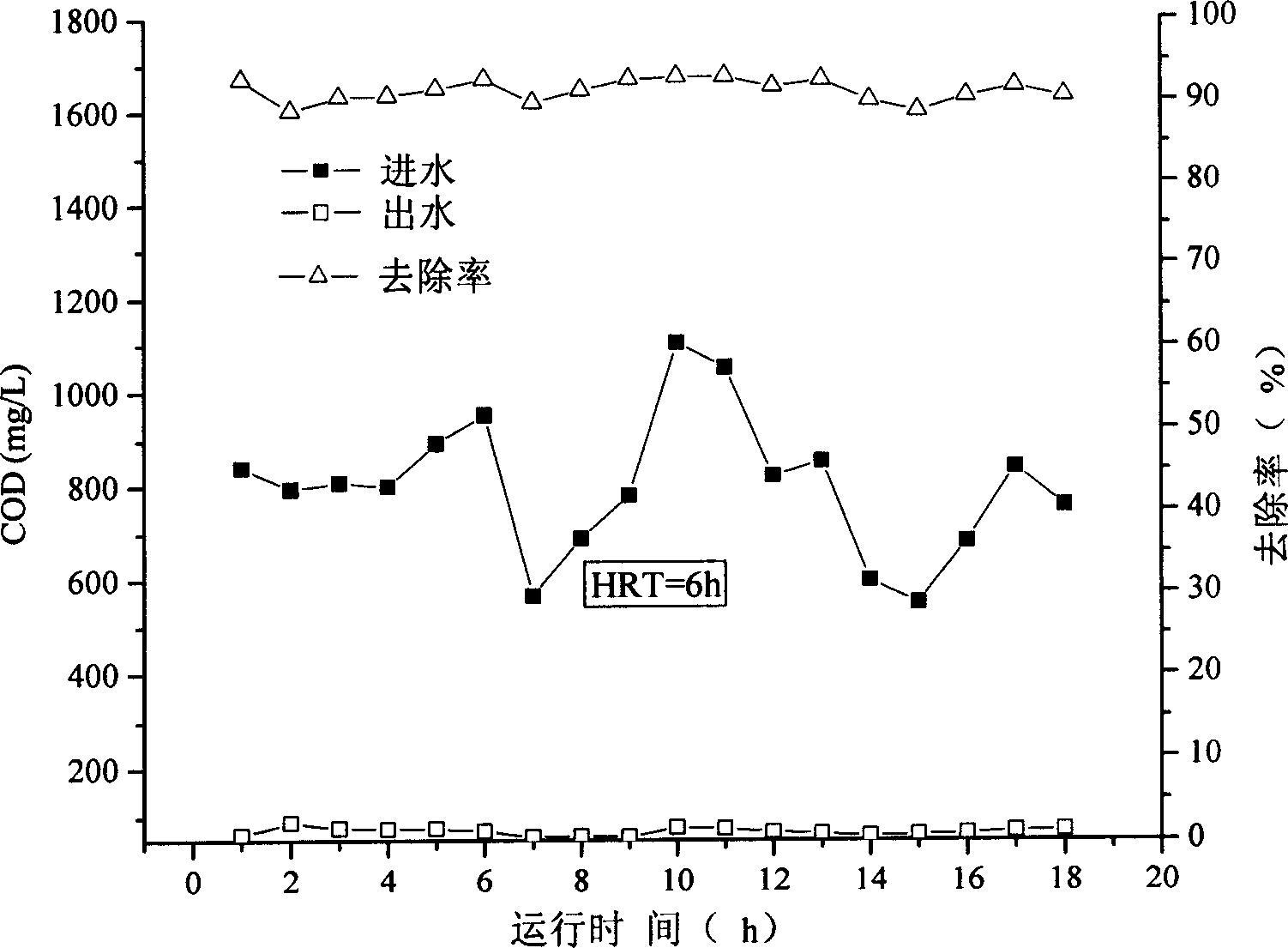

[0035] Embodiment 2: Taking raw water as restaurant sewage as an example, the concentration of influent organic matter (calculated as COD) is 600-1200 mg / L.

[0036] Such as figure 2 , when the biological predation method is used to treat restaurant sewage, in order to achieve the two purposes of reducing sludge and degrading organic matter, the reasonable HRT is 6 hours. Under this condition, the average COD removal rate is 90%, and the effluent COD value is less than 100mg / L, which meets the first-level discharge standard (GB28978-2002).

[0037] It can be seen from Table 1 that the organic matter in the raw water is mainly removed in the bacterial dispersion tank, and the removal rate exceeds 40%, while the removal rates of the primary, metazoan and large micro-animal growth tanks are all lower than 20%, and in turn reduce. The total COD removal rate of the system is about 90%.

[0038] R1 section removal rate

R2 section removal rate

R3 section removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com